BRECHTEL STAP 9406 User manual

Instrument Manual Ver. 3.5

STAP 9406

For UAV Reader version 5.4 and firmware version 7.1

BMI PN: 83-00036-01A

February 16, 2021

CONTENTS

Contents

1 Caution 4

1.1 Electro-static discharge .......................... 4

1.2 Shock during shipping ........................... 4

2 Changes 5

3 Contact BRECHTEL 6

3.1 Getting Help ................................. 6

4 Unboxing 7

4.1 Before First Use ............................... 7

5 STAP Overview 9

5.1 Description .................................. 9

5.2 Theory of Operation ............................ 10

Introduction ................................ 10

Absorption Coefficient Correction ................... 11

5.3 Component Technical Descriptions ................... 12

5.4 STAP Options ................................. 13

5.5 STAP Specifications ............................. 15

6 System Setup 16

6.1 Packing List .................................. 16

83-00036-01A STAP 9406 Page 1 of 46

CONTENTS

6.2 Assembly ................................... 16

6.3 Tubing Connections ............................ 17

6.4 Electrical Connections ........................... 17

6.5 Communication Connections ....................... 18

Computer Connections ......................... 20

6.6 Mounting ................................... 20

7 Operating the STAP 23

7.1 Electrostatic Discharge Practices ..................... 24

7.2 Changing the Filters ............................ 25

7.3 White filter check / filter initialization .................. 28

7.4 Startup & Shutdown ............................ 29

7.5 Front Panel & Firmware .......................... 29

SD Card Menu ............................... 30

Filter Menu ................................. 30

STAP Control Menu ............................ 30

Display Menu ............................... 31

Date & Time Menu ............................ 31

COM Defaults Menu ........................... 31

Main Defaults Menu ........................... 31

Diagnostics Menu ............................. 32

Calibration Values Menu ........................ 32

Raw Readings Menu ........................... 32

Manufacture Info Menu ......................... 32

7.6 Data Files ................................... 33

SD Card ................................... 33

Data File Format ............................. 33

7.7 UAV Reader Software ............................ 36

83-00036-01A STAP 9406 Page 2 of 46

CONTENTS

7.8 External Serial Commands ........................ 39

8 Maintenance 41

8.1 Cleaning the STAP .............................. 41

9 STAP Errors 42

10 Troubleshooting 43

11 Appendix 44

11.1 Updating the STAP firmware ....................... 44

11.2 Calibrating the STAP ............................ 45

Sample Flow LFE ............................. 45

83-00036-01A STAP 9406 Page 3 of 46

1 Caution

1 Caution

Read this section before running your BRECHTEL instrument. This device has the fol-

lowing operating conditions that can be hazardous or harmful to your product without

proper care.

1.1 Electro-static discharge

WARNING:

EXTREME ELECTRICAL SHOCK SENSITIVITY!

Ground yourself before handling STAP

Move STAP only after placing in anti-static bag

Ground STAP using supplied grounding strap after install

Remove RED BRACKET RED SCREWS before first use – replace for ship-

ping – use supplied shorter ‘non-red-head’ screws for operation

Handle the unit during filter changes and other activities by the metal

components, avoid touching the circuit boards and ground yourself be-

fore touching the unit.

1.2 Shock during shipping

If the shock watch installed on the shipping case has tripped, contact BRECHTEL. Oper-

ate the unit to confirm proper operation before using for actual measurements.

83-00036-01A STAP 9406 Page 4 of 46

2 Changes

2 Changes

Change Description Page Date Author

v2.6 Update commands N/A 5/24/2018 FJB

v3.1 Update software discussion Various 10/26/2018 FJB

v3.2 Add new pictures, ESD Various 12/8/2018 FJB

v3.3 RS232 hexadecimal command Various 12/12/2018 FJB

v3.4 Add firmware update procedure Appendix 5/14/2019 FJB

v3.5 Add calibrator description Appendix 2/16/2021 FJB

83-00036-01A STAP 9406 Page 5 of 46

3 Contact BRECHTEL

3 Contact BRECHTEL

3.1 Getting Help

Contact BRECHTEL for any questions or assistance with this product. Include the model and

serial numbers when

contacting Brechtel.

1789 Addison Way

Hayward, California 94544

Telephone: (510) 732-9723

Fax: (510) 732-9153

Email: [email protected]

83-00036-01A STAP 9406 Page 6 of 46

4 Unboxing

4 Unboxing

Each BRECHTEL STAP is inspected and tested in-house at BRECHTEL to ensure out of

the box operation upon delivery. Prior to opening, inspect the packaging container and

ShockWatch impact indicators.

Carefully open the package and inspect the instrument and any accessories for broken

parts, scratches, dents or other signs of damage incurred during shipping. Notify BMI

within 2 days of receiving the package if the shock indicator (Fig 1) has activated or of

any other visible damage.

Retain all shipping

packaging, foam inserts

and cushions to ensure a

safe delivery should the

instrument need to be

returned.

Notify BMI within 2 days of receiving your product if the shock indicator has activated

and/or there is any other visible damage.

Verify the contents of the shipment using the information provided in this manual.

Figure 1: The black

arrows on the shock-

watch indicate the

package experienced

excessive shock dur-

ing shipping. Red ar-

rows indicate no shock

above the G level indi-

cated.

4.1 Before First Use

The red shipping bracket and two red-headed bolts must be removed before first use.

The red-headed bolts must be replaced with the shorter bolts provided.

83-00036-01A STAP 9406 Page 7 of 46

4 Unboxing

Figure 2: Remove the

red brackets and bolts,

be sure to replace be-

fore shipping.

83-00036-01A STAP 9406 Page 8 of 46

5 STAP Overview

5 STAP Overview

5.1 Description

The STAP has been designed in a small and light form factor for applications where

space, weight and power availability are important constraints. For example, the STAP

has been deployed on-board Unmanned Aerial Vehicles (UAVs) over the Arctic and on

tethered balloons. The STAP measures the change in light attenuation once per second

through a filter upon which the particle sample is collected. A clean reference filter is

employed on which no particles are deposited and through which the light attenuation

is also measured. From the change in light attenuation the aerosol light absorption co-

ecient may be derived. If the mass absorption cross-section (MAC) of the aerosol is

known, then dividing the absorption coecient by the MAC allows the mass concentra-

tion of absorbing aerosol to be determined.

The STAP sample flow rate is measured by a precision laminar flow element on the in-

let and controlled in real-time by modulating the speed of the integrated vacuum pump.

The STAP has a single sample filter and a single reference filter through which the sam-

ple flow passes downstream of the sample filter. For applications requiring multiple

sample channels, Brechtel oers the Model 2901 TAP with 8 sample filter spots and 2

reference filter spots.

The STAP uses 10-mm diameter, glass-fiber filters (Brechtel STAP-FIL100). These fil-

ters are made of two fibrous layers, borosilicate glass fibers overlaying a cellulose fiber

backing material (for strength and stability). The cellulose fiber layer is thought to take

up water under conditions of high humidity, which is one reason the STAP sample flow

should be dried before entering the unit to decrease the risk of condensation within the

instrument. Contact Brechtel if you require a sample flow drying solution.

The STAP does not require an external computer for data logging and instrument con-

trol. The internal software in the STAP provides the functionality for measuring signals

(light intensity reaching the detectors, flow rate, sample temperature and pressure) and

controlling the hardware (light source, vacuum pump, saving data to SD card).

When combined with the STAP Graphical User Interface UAV Reader Software, the STAP

reports the change in light transmission through the filter. The UAV Reader uses the

83-00036-01A STAP 9406 Page 9 of 46

5 STAP Overview

USB connection to communicate with the STAP. All data collected is saved and displayed

in real time for analysis. Software communication to the STAP for remote control of

the instrument is established through the serial port on the main control board of the

instrument using the RS-232 protocol.

5.2 Theory of Operation

Introduction

Light absorption in a medium can be quantitatively described using the Beer-Lambert

Law

I=I0e−σ[λ]l

,(1)

where Iand I0are the output and input intensity of light in Watts per square meter pass-

ing through an absorbing medium, σis the medium’s attenuation coecient in inverse

meters at wavelength λin meters, and lis the path length in meters through the medium.

In order to apply this to a light absorption photometer the critical assumption is made

that absorption through a length of air at a given time is equivalent to filtering out the

absorbing species from the air on a filter and passing the light through this instead. If

this is true, then in a given time period Δtthis can be expressed as

I(t) = I(t−Δt)e

−σPSAP[λ]QPSAPΔt

APSAP ,(2)

where I(t)is the intensity of the light reaching the detector at any given time, σPSAP[λ]is

the average, wavelength-dependent absorption coecient of the air parcel that passed

through the filter in Δt,APSAP is the filter area, and QPSAP is the flow through the filter

area. APSAP,QPSAP, and Δtdefine the length of the air parcel passing through the filter

area.

The PSAP label is used here to match the equations described below for further correc-

tions of the absorption coecient. This analysis is not unique to the PSAP.

Unfortunately, this assumption does not take into account the filter material or the prop-

erties of the bulk developed in depositing the particles both on and in the filter, but we

83-00036-01A STAP 9406 Page 10 of 46

5 STAP Overview

can define a filter-loading correction factor, f(τ), determined empirically, to correct for

this, resulting in

I(t) = I(t−Δt)e

−σPSAP[λ]QPSAPΔt

APSAP

1

f(τ)(3)

With some minor rearrangement this becomes

σPSAP[λ] = f(τ)APSAP

QPSAPΔtln I(t−Δt)

I(t),(4)

the most basic description of an absorption photometer’s operation.

Absorption Coefficient Correction

The analysis below follows ”Comment on ‘Calibration and Intercomparison of Filter-

Based Measurements of Visible Light Absorption by Aerosols’” by John A. Ogren 2010.

Eqn. 12 in the above work is

σap[λ] = 0.85 QPSAP

Qmeas Ameas

APSAP σPSAP[λ]

K2

−K1

K2

σsp[λ].(5)

Here σap is the aerosol absorption coecient, σsp is the aerosol scattering coecient,

K1=0.02 ±0.02 and K2=1.22 ±0.20 are empirical coecients defined by the

equation

0.85σPSAP =K1σsp +K2σap,(6)

and Qis the sample flow through both the sample and reference channel, and Ais the

area of each sensor spot. Here

f(τ) = (1.0796τ+0.71)−1(7)

is the experimentally determined correction function for filter loading,

I(t) = ⟨color −dark⟩t

⟨colorref −darkref⟩t

(8)

83-00036-01A STAP 9406 Page 11 of 46

5 STAP Overview

is the ratio of the average intensity of one color at the sample spot to the reference spot

over time period Δt, and τ=I(t)

Iwf is the filter transmission. To calculate the transmission

we use the color ratio from the most recent △t, e.g. for a 5 sec average use the color

ratio from the current 5 second interval, not the previous 5 second interval, or the full

10 seconds used for each measurement. Iwf is the intensity ratio measured while doing

the white filter check. In our instrument QPSAP =Qmeas and APSAP =Ameas, so Eqn. 12

simplifies to

σap[λ] = 0.85 σPSAP[λ]

K2

−K1

K2

σsp[λ].(9)

Depending on the version of software you have, you may have an option to define σsp. If

you don’t have this option, then the program actually calculates

σap[λ] = 0.85 σPSAP[λ]

K2

(10)

instead.

Due to computational limitations in the STAP firmware, absorption co-

ecient values calculated in real-time by the firmware have higher un-

certainties (15%) than values calculated by post-processing the raw data

using the IGOR software routine provided by BRECHTEL. The post-processing

also allows the scattering correction to be applied, which is NOT applied

within the firmware.

5.3 Component Technical Descriptions

The BRECHTEL STAP includes four separate components.

Component 1 STAP main assembly (body, detector board, main board, pump all

integrated to ’L’ bracket mount)

Component 2 A front panel display connected by ribbon cable to the main board.

Component 3 A sample laminar flow element (LFE) assembly to measure the sam-

ple volume flow rate.

83-00036-01A STAP 9406 Page 12 of 46

5 STAP Overview

Component 4 A ship kit with weatherproof case, power supply, spare filters, tweez-

ers, orings, cables and other items to operate the unit and change

filters.

Figure 3: Major compo-

nents of the STAP.

5.4 STAP Options

There are several optional accessories external to the device that can be added at any

time depending on your changing measurement needs.

83-00036-01A STAP 9406 Page 13 of 46

5 STAP Overview

Table 1: STAP Accessories

PN Option Description

8008 0.5 µm Round Jet Impactor Remove particles larger than 0.5 µm at

0.6 l min−1

8009 1.0 µm Round Jet Impactor Remove particles larger than 1.0 µm at

0.6 l min−1

STAP-

FIL250

Pack of 250 10 mm glass fiber

filters for 9406 STAP

Consumeable sample and reference filters

ACC-

STAPKit

Maintenance Kit for 9406 STAP Orings, grease, cleaning tools, etc. to

maintain your STAP

ACC-PWR Additional 12 VDC power supply

for ground operation of any

ACCESS module

Duplicate supply to operate STAP in two

locations

ACC-PC Computer loaded with UAV

Reader Software

Easily operate STAP in multiple locations.

83-00036-01A STAP 9406 Page 14 of 46

5 STAP Overview

5.5 STAP Specifications

Table 2: STAP Specifications

Description Value

Wavelengths 450, 525, 624 nm

Sample flow 0.5 to 1.7 lpm

Vacuum Requirement None

Noise level (1 sigma) ±0.2Mm−1(0.02ugm−3absorbing mass)

Filter Glass fiber, 10 mm dia

Number of Sample Spots 1

Number of Reference Spots 1

Communications USB and RS-232

Operating Temperature -20 to 35°C

Operating Pressure 200-1,100 mb

Operating Humidity 0-95% RH non-condensing

Physical size 5.3 x 4.3 x 3.9 in/13.5 x 10.9 x 9.9 cm

Weight 1.45 lbs/0.66 kg

Supply voltage 12 VDC

Power usage 10 watts

Mounting Multiple hard mounting points through metal body

brackets

83-00036-01A STAP 9406 Page 15 of 46

6 System Setup

6 System Setup

6.1 Packing List

The STAP will arrive in a sturdy weatherproof case holding the STAP base unit and the

ship kit. If accessories were ordered with the STAP they may be packaged in the case or

in additional boxes.

See the Appendix for a complete list of all the parts that come with the STAP. Table 3

shows the parts needed to prepare the STAP for operation.

6.2 Assembly

The STAP will arrive with the front display and sample LFE uninstalled. Follow the dis-

cussion below together with the figure and table to assemble the various pieces.

Figure 4: View of STAP assembly. Numbers refer to table items.

Table 3: STAP Assembly Parts

# Description QTY

1 STAP Base Unit 1

2 Front Panel Display 1

3 Display Ribbon Cable 1

4 Sample LFE Assy 1

5 Ship Kit 1

6 Power supply 1

83-00036-01A STAP 9406 Page 16 of 46

6 System Setup

6.3 Tubing Connections

Item 7 (filter in ship kit) in Fig. 4 is a pump muer only used to reduce the pump noise

and may be removed. Slide the black tubing of item 7 over the clear tygon tubing from

the pump exhaust to attach the filter if desired.

Connect the sample LFE assembly item 4 in Fig. 4 to the metal barb fitting on the STAP

base unit item 1 as shown in the figure using the black conductive tubing supplied. Be

sure to connect the LFE so the small ports with the red and black tubing are closest to

item 1.

Figure 5: Connecting LFE dierential pressure tubing,

sample thermistor and DC power.

In figure 5 ’PS1’ denotes ’pressure sensor 1’. Connect the red tube labelled ’PS1 Lower’

to the barb on PS1 closest to the green circuit board. Connect the black tube labelled ’PS1

Upper’ to the barb on PS1 farthest from the green circuit board. Connect the red tube

labelled ’PS2’ to the single barb on Ps2, this is the total pressure sensor.

6.4 Electrical Connections

When connecting ribbon cable item 3 in Fig. 4 be very careful that it is inserted per-

pendicular to the mating brown connector on the circuit board. Be sure to connect the

83-00036-01A STAP 9406 Page 17 of 46

6 System Setup

provided display ribbon cable to the main board before applying power if the instrument

will be configured using the user interface via the display.

Warning: Be sure the black colored side at the end of the ribbon is against

the darker brown connector clamping piece on the mating connector.

Do NOT connect or disconnect the ribbon cable while power is applied.

Connect the AC-DC power supply to the power input connector on two-pin connector

item 5 in Fig. 5. Connect item 5 to main board to apply power. To facilitate the use of a

battery to power the STAP, DC voltages between 10 and 15 Volts may be used and should

be connected to the Molex power in connector provided with the unit. Any AC adapter

with an output of 10-15 Volts DC at 1 AMP can be used to power the STAP. The instrument

firmware automatically runs when power is connected. Ensure the power plug is fully

seated in the connector before connecting the instrument to a computer.

Connect the sample thermistor attached to the sample LFE to the connector item 1 in Fig.

5 on the main circuit board.

If the vacuum pump 2-pin connector is not connected to the main board, then connect

it to the receptacle on the main board near the pump head.

6.5 Communication Connections

Connect the various cables provided with the STAP as described in the table below.

Table 4: STAP Cable Connections. Numbers refer to figure below.

Port Description

1. Prog ↔ Data Toggle switch for firmware upgrades. Leave in Data mode

unless performing firmware upgrade.

2. USB Port Micro USB port for communication with computer running

UAV Reader software.

3. COM Port Serial communication port between the STAP and user PC.

4. SPI Bus Not currently used

83-00036-01A STAP 9406 Page 18 of 46

6 System Setup

Figure 6: STAP commu-

nication connections.

Be sure the program/data toggle switch item 1 in figure 6 is in DATA mode (toggled away

from green circuit board) during normal operation. Only toggle the switch to update the

firmware. Switch back to data position after the firmware is updated.

Connect the USB cable provided in the ship kit to the USB mini connector on the main

board, item 2 in figure 6.

The RS232 port item 3 in figure 6 is used to send remote control commands directly to

the STAP from a user computer using the cable provided in the ship kit. The STAP uses a

simple 3 wire RS232 connection. The board connector uses a 3 position C-Grid SL con-

nector. A DB9 adapter is included with each STAP ship kit.

The detailed settings for the serial port: RS232: 8 data bits, 1 stop bit, no parity,

Baud rates: 38.4k, 57.6k, 115.2k and USB with 230k.

83-00036-01A STAP 9406 Page 19 of 46

Table of contents

Popular Industrial Equipment manuals by other brands

SEW-Eurodrive

SEW-Eurodrive DR Series Addendum to the operating instructions

Facom

Facom WV.1105 instruction manual

Fromm

Fromm FS395 Series TRANSLATION OF ORIGINAL INSTRUCTIONS

EASTMAN

EASTMAN TRIGGER PLUS Knifebox Instruction manual & parts list

SICK

SICK SIM2500 operating instructions

ASTEC

ASTEC 40 Series Operation and maintenance manual

Finn

Finn T90-II HydroSeeder Operator's manual

Eaton

Eaton Airflex CB Installation & operation

ABB

ABB HT842223 Operation manual

Electrostatic Technology

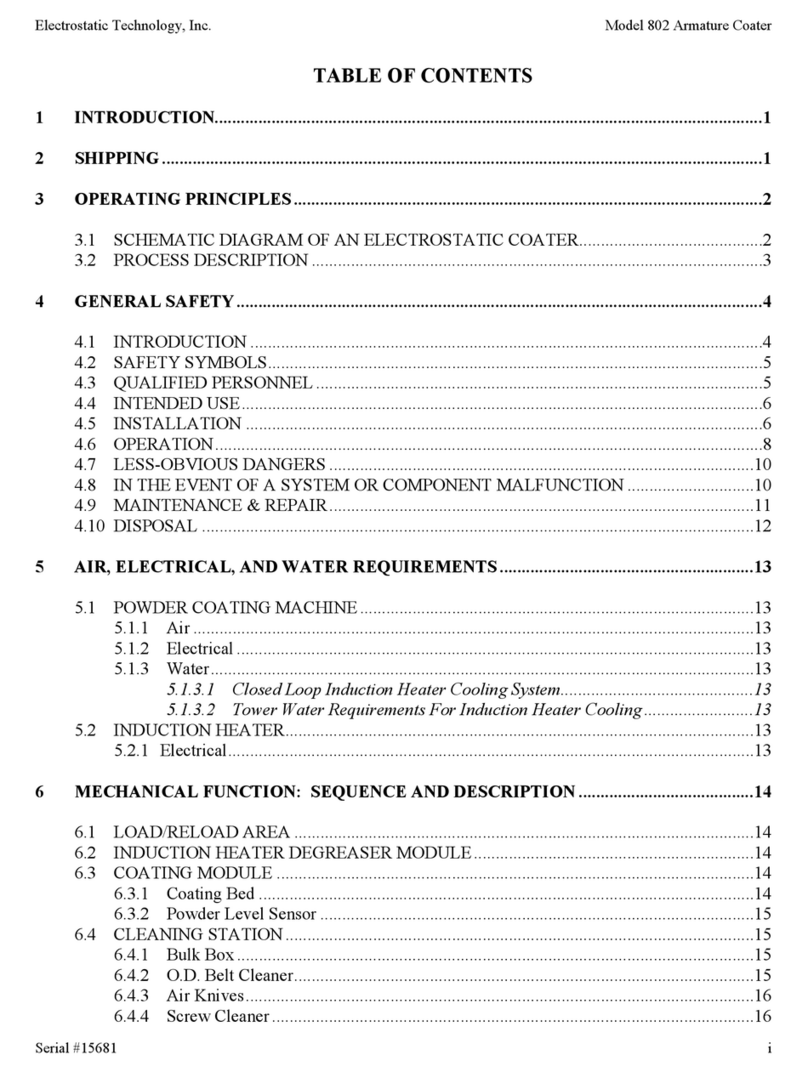

Electrostatic Technology 802 manual

Dustcontrol

Dustcontrol TPR 50 Original instructions

Bastian Solutions

Bastian Solutions Shoe Sorter Installation and maintenance instructions