Electrostatic Technology 802 User manual

Electrostatic Technology, Inc. Model 802 Armature Coater

Serial #15681 i

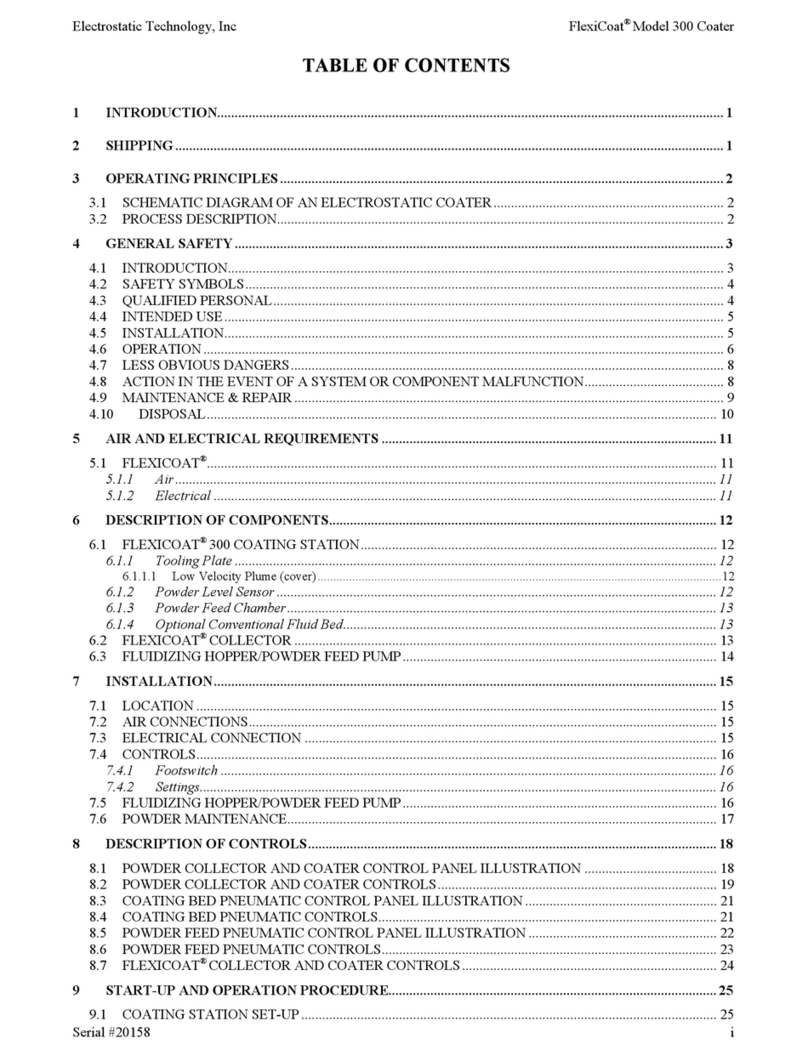

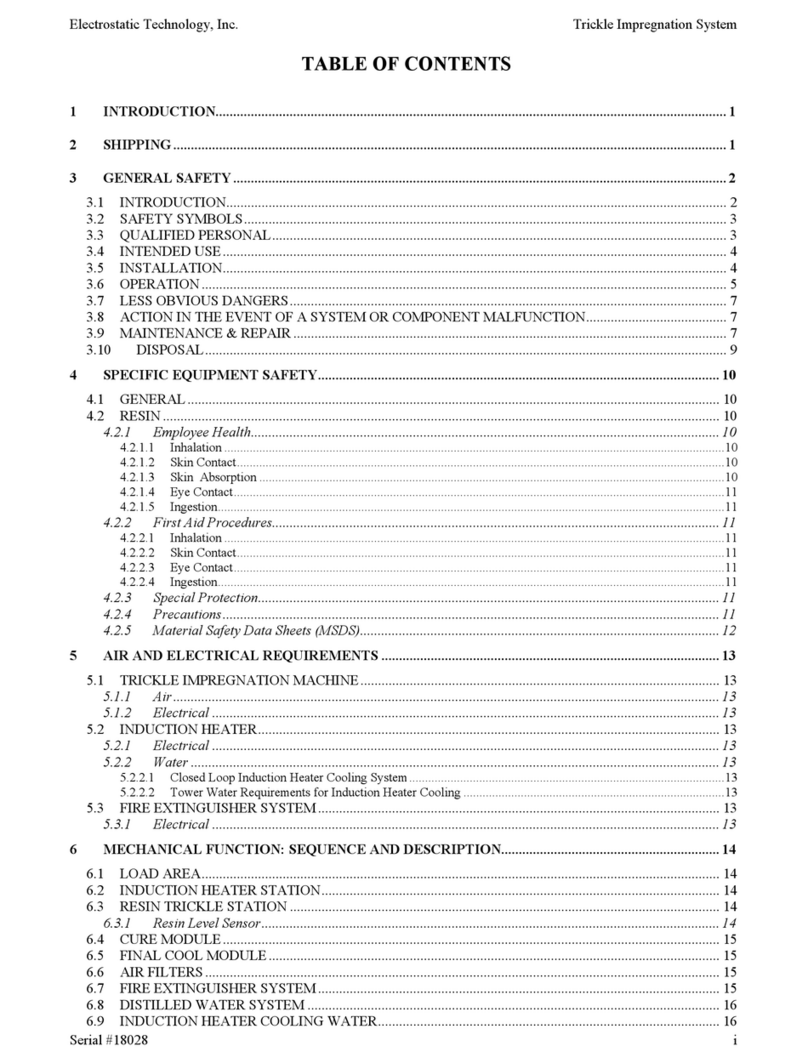

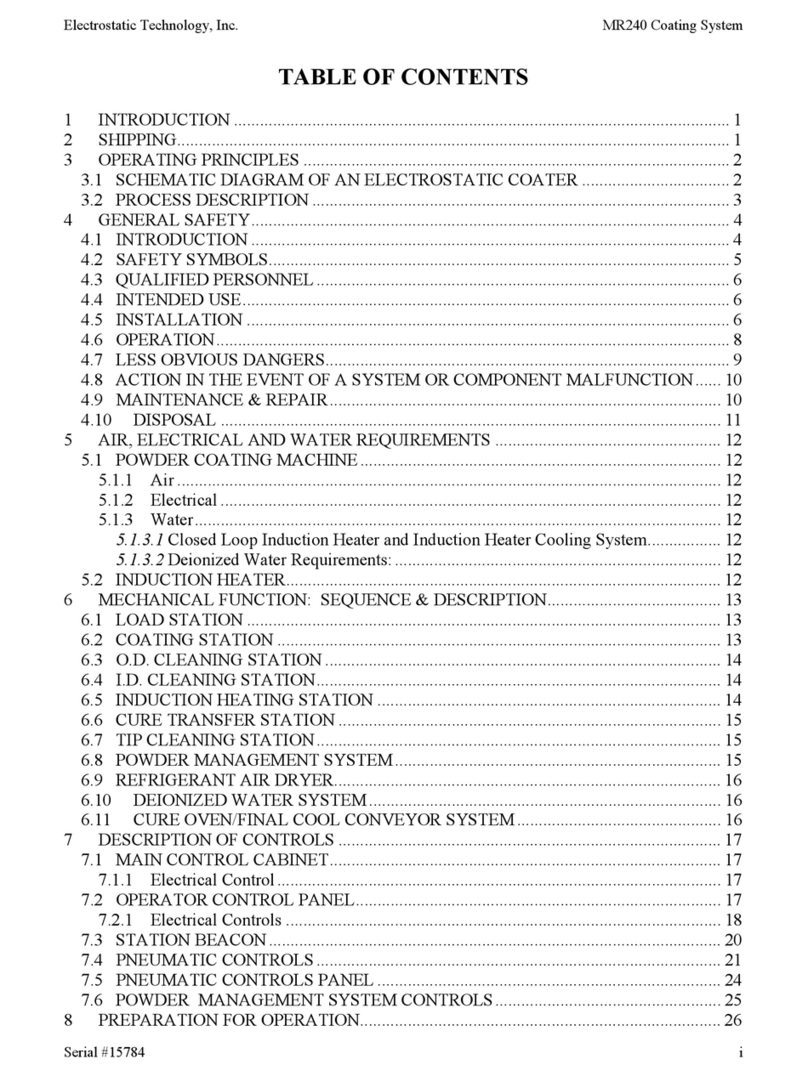

TABLE OF CONTENTS

1 INTRODUCTION.............................................................................................................................1

2 SHIPPING .........................................................................................................................................1

3 OPERATING PRINCIPLES ...........................................................................................................2

3.1 SCHEMATIC DIAGRAM OF AN ELECTROSTATIC COATER..........................................2

3.2 PROCESS DESCRIPTION .......................................................................................................3

4 GENERAL SAFETY ........................................................................................................................4

4.1 INTRODUCTION .....................................................................................................................4

4.2 SAFETY SYMBOLS.................................................................................................................5

4.3 QUALIFIED PERSONNEL ......................................................................................................5

4.4 INTENDED USE.......................................................................................................................6

4.5 INSTALLATION ......................................................................................................................6

4.6 OPERATION.............................................................................................................................8

4.7 LESS-OBVIOUS DANGERS .................................................................................................10

4.8 IN THE EVENT OF A SYSTEM OR COMPONENT MALFUNCTION .............................10

4.9 MAINTENANCE & REPAIR.................................................................................................11

4.10 DISPOSAL ..............................................................................................................................12

5 AIR, ELECTRICAL, AND WATER REQUIREMENTS ..........................................................13

5.1 POWDER COATING MACHINE ..........................................................................................13

5.1.1 Air ................................................................................................................................13

5.1.2 Electrical ......................................................................................................................13

5.1.3 Water............................................................................................................................13

5.1.3.1 Closed Loop Induction Heater Cooling System............................................13

5.1.3.2 Tower Water Requirements For Induction Heater Cooling .........................13

5.2 INDUCTION HEATER...........................................................................................................13

5.2.1 Electrical........................................................................................................................13

6 MECHANICAL FUNCTION: SEQUENCE AND DESCRIPTION ........................................14

6.1 LOAD/RELOAD AREA .........................................................................................................14

6.2 INDUCTION HEATER DEGREASER MODULE ................................................................14

6.3 COATING MODULE .............................................................................................................14

6.3.1 Coating Bed .................................................................................................................14

6.3.2 Powder Level Sensor ...................................................................................................15

6.4 CLEANING STATION ...........................................................................................................15

6.4.1 Bulk Box ......................................................................................................................15

6.4.2 O.D. Belt Cleaner.........................................................................................................15

6.4.3 Air Knives....................................................................................................................16

6.4.4 Screw Cleaner ..............................................................................................................16

Electrostatic Technology, Inc. Model 802 Armature Coater

ii Serial #15681

6.5 POWDER MANAGEMENT SYSTEM ..................................................................................17

6.6 INDUCTION HEATING MODULE.......................................................................................19

6.7 CURE MODULE.....................................................................................................................19

6.8 FINAL COOL MODULE........................................................................................................19

6.9 REFRIGERANT AIR DRYER................................................................................................19

6.10 DEIONIZED WATER SYSTEM ............................................................................................19

6.11 INDUCTION HEATER COOLING WATER ........................................................................20

6.12 MAIN CONTROL CABINET.................................................................................................20

7 DESCRIPTION OF CONTROLS.................................................................................................21

7.1 OPERATOR MAIN CONTROL PANEL ...............................................................................21

7.2 OPERATOR MAIN CONTROLS...........................................................................................22

7.3 COATER CONTROL PANEL................................................................................................25

7.4 COATER CONTROLS ...........................................................................................................25

7.5 CLEANING CONTROL PANEL ...........................................................................................26

7.6 CLEANING CONTROLS .......................................................................................................27

7.7 POWDER MANAGEMENT SYSTEM CONTROLS ............................................................28

8 SPECIFICE EQUIPMENT SAFETY...........................................................................................29

8.1 GENERAL...............................................................................................................................29

8.2 POWDER.................................................................................................................................29

8.2.1 Employee Health..........................................................................................................29

8.2.1.1 Inhalation......................................................................................................29

8.2.1.2 Skin Contact..................................................................................................29

8.2.1.3 Eye Contact...................................................................................................30

8.2.1.4 First Aid Procedures.....................................................................................30

8.2.2 Special Protection ........................................................................................................30

8.2.3 Precautions...................................................................................................................30

8.2.4 Material Safety Data Sheets (MSDS) ..........................................................................30

9 PREPARATION FOR OPERATION...........................................................................................31

9.1 INITIAL SYSTEM INSTALLATION ....................................................................................31

9.2 GENERAL...............................................................................................................................33

9.3 COATER..................................................................................................................................34

9.3.1 Coating Bed .................................................................................................................34

9.3.2 Powder Deposition.......................................................................................................34

9.3.3 High Voltage Adjustment ............................................................................................35

9.4 POWDER MANAGEMENT SYSTEM ..................................................................................35

9.4.1 Loading Powder...........................................................................................................35

9.4.2 Powder Maintenance....................................................................................................35

9.5 CLEANERS.............................................................................................................................35

9.5.1 O.D. Cleaner ................................................................................................................35

9.5.2 Air Knives....................................................................................................................36

9.5.3 Screw Cleaners ............................................................................................................36

9.6 INDUCTION HEATERS ........................................................................................................36

Electrostatic Technology, Inc. Model 802 Armature Coater

Serial #15681 iii

10 OPERATION ......................................................................................................................................37

11 START-UP & OPERATION PROCEDURE...................................................................................38

11.1 LOCAL MODE-COATING MACHINE.....................................................................................38

11.2 EXTERNAL MODE-COATING ................................................................................................39

12 SHUTDOWN PROCEDURE ............................................................................................................40

12.1 LOCAL MODE SHUTDOWN-COATER ..................................................................................40

12.2 EXTERNAL MODE SHUTDOWN-COATER...........................................................................40

12.3 POWDER HANDLING...............................................................................................................40

12.3.1 Powder Management System...........................................................................................41

12.4 POWDER/COLOR CHANGE ....................................................................................................41

13 MAINTENANCE................................................................................................................................42

13.1 GENERAL...................................................................................................................................42

13.2 COMPRESSED AIR SYSTEM...................................................................................................42

13.2.1 Air Line ...........................................................................................................................42

13.2.2 Refrigerant Air Dryer.......................................................................................................42

13.3 FLUIDIC BED.............................................................................................................................43

13.3.1 Installation of Porous Plate ..............................................................................................43

13.3.2 Powder Level Sensor .......................................................................................................44

13.4 POWDER COLLECTOR ............................................................................................................44

13.4.1 Lower Fluidizing Hopper.................................................................................................45

13.4.2 Installation of Porous Plate ..............................................................................................45

13.4.3 Filter Cartridges ...............................................................................................................46

13.4.4 Differential Pressure Gauge.............................................................................................46

13.5 O.D. CLEANER ..........................................................................................................................46

13.6 INDUCTION HEATER...............................................................................................................47

13.7 COOLING BLOWERS................................................................................................................47

13.8 ROTO-FLO CONVEYOR...........................................................................................................47

13.9 MOTORS & GEARS...................................................................................................................47

14 PREVENTATIVE MAINTENANCE SCHEDULE ........................................................................48

14.1 DAILY .........................................................................................................................................48

14.2 WEEKLY.....................................................................................................................................48

14.3 MISCELLANEOUS ....................................................................................................................49

15 PART CHANGEOVER......................................................................................................................50

15.1 CHANGEOVER PROCEDURE .................................................................................................50

15.1.1 Changing From Smaller To Larger Parts........................................................................50

15.1.2 Changing From Larger To Smaller Parts.........................................................................50

Electrostatic Technology, Inc. Model 802 Armature Coater

iv Serial #15681

16 TROUBLESHOOTING .....................................................................................................................51

16.1 COATER......................................................................................................................................51

16.2 POWDER COLLECTOR ............................................................................................................55

16.3 CONVEYOR CLUTCH ..............................................................................................................55

16.4 BAD PARTS................................................................................................................................56

17 PATENT INFORMATION................................................................................................................58

18 MANUFACTURER'S MANUALS ...................................................................................................59

19 FLOOR PLAN ....................................................................................................................................60

20 PNEUMATIC SCHEMATIC ............................................................................................................60

21 ELECTRICAL SCHEMATIC ..........................................................................................................60

22 SPARE PARTS ...................................................................................................................................61

Electrostatic Technology, Inc. Model 802 Armature Coater

Serial #15681 v

TABLE OF FIGURES

FIGURE 1A: 5HP POWDER COLLECTOR................................................................................................18

FIGURE 1B: SCRAP POWDER COLLECTOR ..........................................................................................18

FIGURE 2: PIPING DIAGRAM ................................................................................................................32

FIGURE 3: LEVEL SENSOR PROBE TUBE...........................................................................................34

Table of contents

Other Electrostatic Technology Industrial Equipment manuals