Bredel APEX35 User manual

1

Translation of the manual

To get the translation of the manual in your language,

use the disc or scan the QR code.

Gebruik de schijf of scan de QR code om de vertaling van de

handleiding in uw taal te krijgen.

Um die Übersetzung des Handbuchs in Ihrer Sprache zu erhalten,

verwenden Sie die Disk oder scannen Sie den QR-Code.

Para obter a tradução do manual no seu idioma,

use o disco ou faça a leitura do código QR.

Para obtener la traducción del manual en su idioma,

utilice el disco o escanee el código QR.

Pour accéder à la traduction du manuel dans votre langue,

utilisez le disque ou scannez le code QR.

Per ottenere la traduzione del manuale nella propria lingua,

utilizzare il disco o acquisire il codice QR.

Chcete-li získat překlad příručky ve vašem jazyce,

použijte disk nebo naskenujte QR kód.

Ha a kézikönyvet saját nyelvén szeretné, akkor használja

a lemezt vagy szkennelje be a QR kódot.

Aby pobrać instrukcję przetłumaczoną na Państwa język,

prosimy skorzystać z płyty lub zeskanować kod QR.

Для получения руководства на своем языке установите

диск или отсканируйте QR-код.

For at se en oversættelse af vejledningen på dit sprog,

skal du bruge disken eller scanne QR-koden.

Saadaksesi käyttöoppaan omalla kielelläsi,

käytä levykettä tai skannaa QR-koodi.

For å lese håndboken oversatt til ditt eget språk,

bruk platen eller scan QR-koden.

För att få en översättning av handboken på ditt språk,

använda skivan eller skanna QR-koden.

尐噆♥㦻㓚␛ⅴ㌷䤓幼岏⛗䘿䤓幠㦻᧨∎䞷⏘䥧㒥㓺㙞45ⅲ䪐ᇭ

English

Nederlands

Deutsch

Português

Español

Français

Italiano

Česky

Magyar

Polski

Pусский

Dansk

Suomi

Norsk

Svenska

中国

2

Available documents

For the models APEX28 and APEX35, the following documents are available on disc

and website:

•User manual in multiple languages

•Quick reference instructions for the replacement of the pump hose

System requirements

How to use the disc

1 Put the disc in the disc drive.

The disc will start automatically.

2 Select the required language.

The PDF reader program shows the selected user manual.

How to use the website

1 Go to the website www.wmftg.com.

2 Select ‘Bredel’, ‘Manual’ and then the required language.

3 Open or save the user manual.

The PDF reader program shows the selected user manual.

How to use the QR code

1 Scan the QR code with your smartphone or tablet.

The app forwards you to the webpage that contains the required language.

2 Open or save the user manual.

The PDF reader program shows the selected user manual.

The replacement instructions are only for users that are familiar with the

replacement procedures in the user manual.

Source Hardware Software

Disc PC with CD drive - internet browser

- PDF reader

Website PC or tablet - internet browser

- PDF reader

QR code Smartphone or tablet with

camera - internet browser

- PDF reader

- App that can scan QR codes

3

Hose pump series

APEX28 and APEX35

Installation, Operation and Maintenance Manual

Environmental

Management

ISO

14001

Quality

Management

ISO

9001

4

© 2015 Watson-Marlow Bredel B.V.

All rights reserved.

The information provided herein may not be reproduced and/or published in any form,

by print, photoprint, microfilm or any other means whatsoever (electronically or

mechanically) without the prior written authorisation of Watson-Marlow Bredel B.V.

The information provided can be changed without prior notification. Watson-Marlow

Bredel B.V. or one of its representatives cannot be held liable for possible damage

resulting from use of this manual. This is an extensive limitation of the liability which

applies to all damage, inclusive of (without limitation) compensating, direct, indirect or

consequential damage, loss of data, income or profit, loss or damage to possessions

and claims of third parties.

Watson-Marlow Bredel B.V. provides the information in this manual "as is" and does not

take any responsibility and does not give any guarantee on this manual or its content.

Watson-Marlow Bredel B.V. rejects all responsibilities and guarantees. Furthermore,

Watson-Marlow Bredel B.V. does not take responsibility for and does not guarantee that

the information in this manual is accurate, complete or up to date.

Names, trade names, brands, etc. used by Watson-Marlow Bredel B.V. may not, as per

the legislation concerning the protection of trade names, be considered as available.

5

CONTENTS

1GENERAL

1.1 How to use this manual .......................................................................... 8

1.2 Original instructions ................................................................................ 8

1.3 Other supplied documentation ................................................................ 8

1.4 Service and support ................................................................................ 8

1.5 Environment and disposal of waste ........................................................ 9

2SAFETY

2.1 Symbols ................................................................................................ 10

2.2 Intended use ......................................................................................... 10

2.3 Use in potentially explosive atmospheres ............................................. 11

2.4 Responsibility ........................................................................................ 11

2.5 Qualification of the user ........................................................................ 12

2.6 Regulations and instructions ................................................................. 12

3 WARRANTY CONDITIONS

4 DESCRIPTION

4.1 Identification of the product ................................................................... 14

4.1.1 Identification of the product ....................................................... 14

4.1.2 Identification of the pump .......................................................... 14

4.1.3 Identification of the gearbox ...................................................... 14

4.1.4 Identification of the electric motor .............................................. 15

4.1.5 Identification of the frequency controller .................................... 15

4.1.6 Identification of the pump hose ................................................. 15

4.2 Construction of the pump ...................................................................... 16

4.3 Operation of the pump .......................................................................... 17

4.4 Pump hose ............................................................................................ 18

4.4.1 General ...................................................................................... 18

4.4.2 Hose compression force adjustment ......................................... 19

4.4.3 Lubrication and cooling ............................................................. 19

4.5 Gearbox ................................................................................................ 20

4.6 Electric motor ........................................................................................ 20

4.7 Available options ................................................................................... 20

5 INSTALLATION

5.1 Unpacking ............................................................................................. 21

5.2 Inspection ............................................................................................. 21

6

5.3 Installation conditions ........................................................................... 21

5.3.1 Ambient conditions .................................................................... 21

5.3.2 Setup ......................................................................................... 21

5.3.3 Pipework ................................................................................... 22

5.3.4 Motor ......................................................................................... 23

5.3.5 Frequency controller ................................................................. 23

5.4 Lifting and moving the pump ................................................................ 24

5.5 Placing the pump .................................................................................. 24

6 COMMISSIONING

6.1 Preparations ......................................................................................... 25

6.2 Commissioning ..................................................................................... 25

7 OPERATION

7.1 Temperature ......................................................................................... 27

7.2 Power rating ......................................................................................... 27

7.3 Performance graphs ............................................................................. 28

7.4 Dry running ........................................................................................... 31

7.5 Hose failure .......................................................................................... 31

7.6 Fluid leakage ........................................................................................ 33

8 MAINTENANCE

8.1 General ................................................................................................. 34

8.2 Maintenance and periodic inspections ................................................. 34

8.3 Cleaning the pump hose ...................................................................... 36

8.4 Changing lubricant ............................................................................... 36

8.5 Replacing the pump hose ..................................................................... 37

8.5.1 Removing the pump hose ......................................................... 37

8.5.2 Cleaning the pumphead ............................................................ 39

8.5.3 Fitting the pump hose ................................................................ 40

8.6 Exchanging replacement parts ............................................................. 42

8.6.1 Replacing the rotor .................................................................... 42

8.6.2 Replacing the bearing, seal ring, shaft and coupling bush ........ 44

8.7 Fitting options ....................................................................................... 48

8.7.1 Fitting a high-level float switch .................................................. 48

8.7.2 Replacing the revolution counter ............................................... 49

9 STORAGE

9.1 Hose pump ........................................................................................... 52

9.2 Pump hose ........................................................................................... 52

7

10 TROUBLESHOOTING

11 SPECIFICATIONS

11.1 Pumphead ............................................................................................ 58

11.1.1 Performance .............................................................................. 58

11.1.2 Materials .................................................................................... 59

11.1.3 Surface treatment ...................................................................... 60

11.1.4 Lubricant table pump ................................................................. 60

11.1.5 Weights ..................................................................................... 61

11.1.6 Torque figures ........................................................................... 62

11.2 Lubricant table gearbox ........................................................................ 63

11.3 Gearbox ................................................................................................ 64

11.4 Electric motor ........................................................................................ 64

11.5 Variable Frequency Drive (VFD) (optional) ........................................... 64

11.6 Parts list ................................................................................................ 65

11.6.1 Ordering parts ........................................................................... 65

11.6.2 Overview ................................................................................... 66

11.6.3 Cover assembly ......................................................................... 67

11.6.4 Pumphead assembly ................................................................. 68

11.6.5 Support assembly ...................................................................... 70

11.6.6 Flange assembly ....................................................................... 71

11.6.7 Lubricant .................................................................................... 71

SAFETY FORM

NOTES

GENERAL

8

1GENERAL

1.1 How to use this manual

This manual is intended as a reference book by means

of which qualified users are able to install, commission

and maintain the hose pumps mentioned on the front

cover.

The manual on the internet

You can find the most recent version of the manual and

translations on www.wmftg.com/literature. On this page,

select ‘Bredel’, ‘Manual’ and the required language.

1.2 Original instructions

The original instructions for this manual have been

written in English. Other language versions of this

manual are a translation of the original instructions.

1.3 Other supplied documentation

Documentation of components such as the gearbox, the

motor and the frequency controller is not included in this

manual. However, if additional documentation is

supplied, you must follow the instructions in this

additional documentation.

1.4 Service and support

For information with respect to specific adjustments,

installation, maintenance or repair jobs which fall

beyond the scope of this manual, contact your Bredel

representative. Make sure you have the following data

at hand:

•Serial number of the hose pump

•Article number of the pump hose

•Article number of the gearbox

•Article number of the electric motor

•Article number of the frequency controller

GENERAL

9

You will find these data on the identification plates or

stickers on the pumphead, the pump hose, the gearbox

and the electric motor. Refer to § 4.1.1.

1.5 Environment and disposal of waste

Inquire within your local government about the

possibilities for reuse or environment-friendly

processing of packaging materials, (contaminated)

lubricant and oil.

CAUTION

Always observe the local rules and regula-

tions with respect to processing (non reus-

able) parts of the hose pump.

SAFETY

10

2SAFETY

2.1 Symbols

In this manual the following symbols are used:

2.2 Intended use

The hose pump is exclusively designed for pumping

suitable products. Every other or further use is not in

conformance with the intended use.

Flammable fluids are not suitable products to be

pumped by this hose pump. This pump is not intended

to operate in potentially explosive atmospheres.

The "Intended use" as laid down in EN 292-1 is "... the

use for which the technical product is intended in

accordance with the specifications of the manufacturer,

inclusive of his indications in the sales brochure". In

case of doubt it is the use, which appears to be its

intended use judging from the construction, execution

and function of the product, and its description in the

user's documentation.

Only use the pump in conformance with the intended

use described above. The manufacturer cannot be held

responsible for damage or harm resulting from use that

WARNING

Procedures which, if not carried out with

the necessary care, may result in serious

bodily harm.

CAUTION

Procedures which, if not carried out with

the necessary care, may result in serious

damage to the hose pump, the surrounding

area or the environment.

Remarks, suggestions and advice.

SAFETY

11

is not in conformance with the intended use. If you want

to change the application of your hose pump, contact

your Bredel representative first.

2.3 Use in potentially explosive atmospheres

The pumphead and drive mentioned in this manual may

be configured to be suitable for use in a potentially

explosive atmosphere. Such a pump meets the

requirements as stated in the European Directive 94/9/

EC (ATEX Directive). Such a pump belongs to: Group II

appliances, category 2 GD bck T4.

See Bredel’s ATEX Instruction manual which is supplied

with pumps configured as mentioned above.

2.4 Responsibility

The manufacturer does not accept any responsibility for

damage or harm caused by not observing the safety

regulations and instructions in this manual and other

supplied documentation, or by negligence during

installation, use, maintenance and repair of the hose

pumps mentioned on the front cover. Depending on the

specific working conditions or accessories used,

additional safety instructions can be required.

Immediately contact your Bredel representative if you

notice a potential danger while using your hose pump.

Use in potentially explosive atmospheres

requires special configuration of the pump.

Contact your Bredel representative for use

in explosive atmospheres.

WARNING

The user of the hose pump is fully respon-

sible for observing local safety regulations

and directives. Observe these safety regu-

lations and directives when using the hose

pump.

SAFETY

12

2.5 Qualification of the user

The installation, use and maintenance of the hose

pump should only be performed by well-trained and

qualified users. Temporary staff and persons in training

may use the hose pump only under the supervision and

responsibility of trained and qualified users.

2.6 Regulations and instructions

•Everyone who works with the hose pump must

be aware of the contents of this manual and

observe the instructions with great care.

•Never change the order of the actions to be

carried out.

•Always store the manual near the hose pump.

WARRANTY CONDITIONS

13

3 WARRANTY CONDITIONS

The manufacturer offers a two-year warranty on all

parts of the hose pump. This means that all parts will be

repaired or replaced free of charge, with the exception

of consumables such as pump hoses, ball bearings,

wear rings, seals and compression rings, or parts which

have been used wrongly, misused, whether or not they

have been intentionally damaged. If genuine Watson-

Marlow Bredel (hereafter called Bredel) parts are not

used, any warranty claim is void.

Damaged parts which are covered by the applicable

warranty conditions can be returned to the

manufacturer. The parts must be accompanied by a

fully filled in and signed safety form, as present in the

back of this manual. The safety form must be applied to

the outside of the shipping carton. Parts which have

been contaminated or which have been corroded by

chemicals or other substances which can pose a health

risk must be cleaned before they are returned to the

manufacturer. Furthermore, it should be indicated on

the safety form which specific cleaning procedure has

been followed, and that the equipment has been

decontaminated. The safety form is required even if the

parts have not been used.

Warranties purporting to be on behalf of Bredel B.V.

made by any person, including representatives of

Bredel B.V., its subsidiaries, or its distributors, which do

not accord with the terms of this warranty shall not be

binding upon Bredel B.V. unless expressly approved in

writing by a Director or Manager of Bredel B.V.

DESCRIPTION

14

4 DESCRIPTION

4.1 Identification of the product

4.1.1 Identification of the product

The hose pump can be identified by identification plates

or stickers on:

A: Pumphead

B: Gearbox

C: Electric motor

D: Pump hose

E: Frequency controller (option)

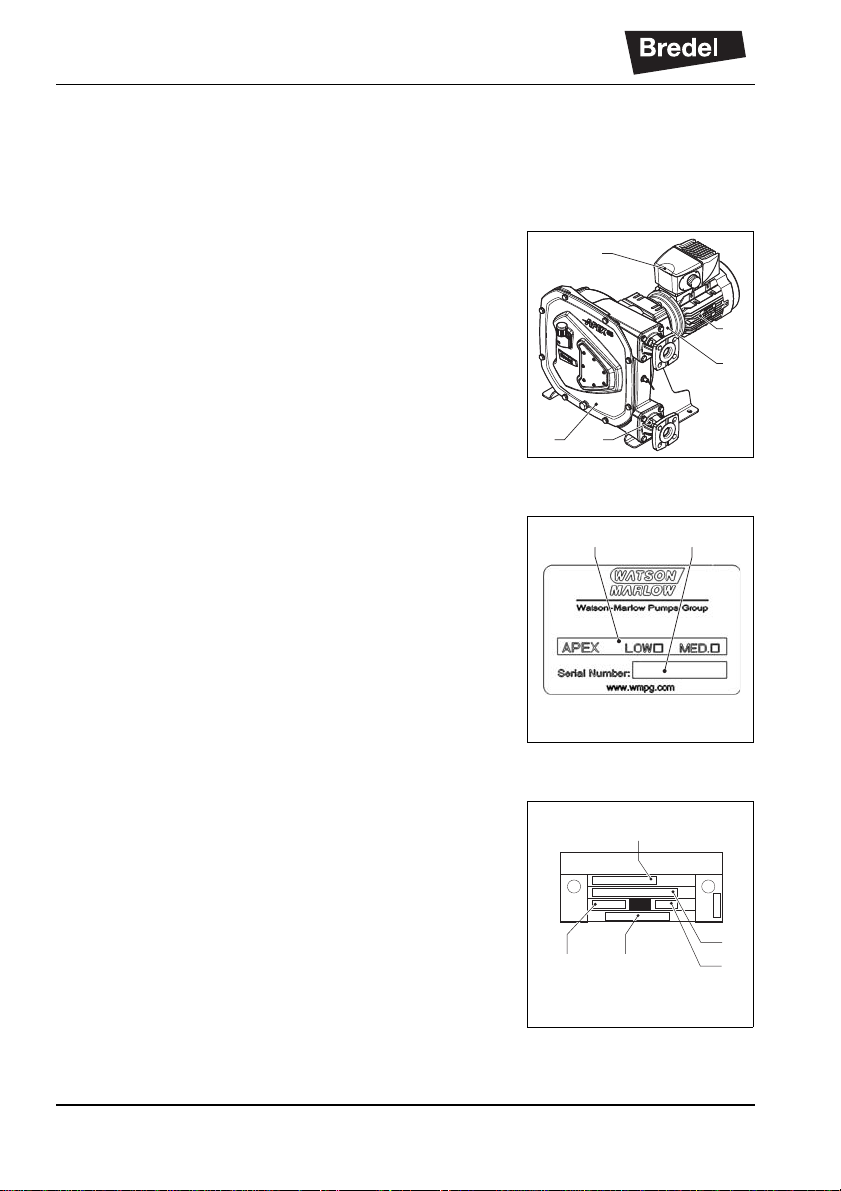

4.1.2 Identification of the pump

The identification plate on the pumphead contains the

following data:

A: Pump type and rotor type (low or medium

pressure)

B: Serial number

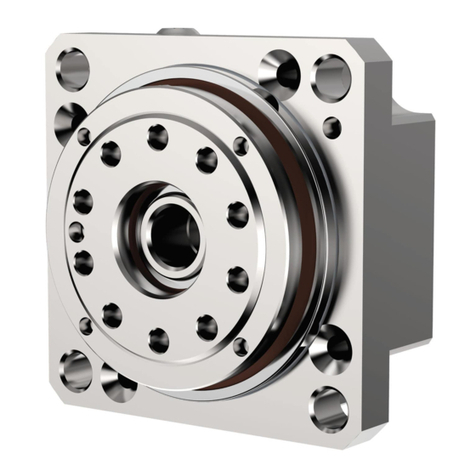

4.1.3 Identification of the gearbox

The identification plate on the gearbox contains the

following data:

A: Article number

B: Serial number

C: Type number

D: Reduction ratio

E: Number of revolutions per minute

E

AD

C

B

BA

min-1

N

o

i

D A B

E

C

DESCRIPTION

15

4.1.4 Identification of the electric motor

The identification plate on the electric motor contains

the following data:

B: Serial number

C: Article number

D: Mains

E: Frequency

F: Speed

G: Power

H: Power factor

I: Current

4.1.5 Identification of the frequency controller

The identification of the Bredel Variable Frequency

Drive (VFD) can be found inside the VFD. Remove the

cover by loosening the two screws. The identification

sticker contains the following data:

A: Article number

B: Serial number

4.1.6 Identification of the pump hose

The identification sticker on the pump hose contains the

following data:

A: Pump type

B: Part code

C: Internal diameter

D: Type of material of inner liner

E: Remarks, if applicable

F: Maximum permissible working pressure

G: Production code

V

S

IP IK

Hz min-1 kW A

COS

C/h%

N

o

U

N

VP

Mf Nm

CF

o

D E F GH I

CB

LS serial number

sn20837003969

Bredel article number E384083

A

B

A

B

C

D

E

F

G

DESCRIPTION

16

4.2 Construction of the pump

A: Cover

B: Rotor

C: Pump hose

D: Pump housing

E: Supports

F: Gearbox

G: Electric motor

H: Frequency controller

A

D

C

E

G

E

F

H

B

DESCRIPTION

17

4.3 Operation of the pump

The heart of the pumphead consists of a specially

constructed pump hose (A) which lies against the inside

of the pump housing (B). The ends of the hose are

connected to the suction and discharge lines (C). A

bearing-mounted rotor (D) with two facing integral

pressing shoes (E) is in the center of the pumphead. It

rotates clockwise.

In phase 1 the lower shoe compresses the pump hose

by the rotational movement of the rotor, forcing fluid

through the hose. As soon as the shoe has passed, the

hose recovers to its original shape due to the

mechanical properties of the material and fluid is drawn

into the hose.

In phase 2 fluid is drawn through the hose by the

(continuous) turning motion of the rotor.

In phase 3, the second integral pressing shoe

compresses the pump hose. Due to the continuous

rotating movement of the rotor new fluid is sucked in

and fluid that is previously drawn in is pressed out by

the shoe. When the first shoe leaves the pump hose,

the second shoe has already occluded the pump hose

and fluid is prevented from flowing back. This method of

liquid displacement is known as the "positive

displacement principle".

AB ECD

DESCRIPTION

18

4.4 Pump hose

4.4.1 General

A: Extruded outer layer made of natural rubber

B: Four nylon reinforcement layers

C: Extruded inner liner

The pump hose liner material should be chemically

resistant to the product being pumped. For each pump

model various hose types are available. Choose the

most appropriate for your application.

The material of the inner liner of the pump hose

determines the hose type. Each hose type is marked by

a unique colour code.

Bredel pump hoses have been carefully machined to

achieve minimum tolerances in wall thickness. It is very

important to guarantee the correct compression of the

pump hose, because:

•When the compression is too high, it creates an

excessive load on the pump and pump hose,

which may reduce the life of the pump hose and

bearings.

•When the compression is too low, it cuts

capacity and causes backflow. Backflow

reduces the life of the pump hose.

B C

A

Hose type Material Colour code

NR Natural rubber Purple

NBR Nitrile rubber Yellow

EPDM EPDM Red

Consult your Bredel representative for

more detailed information about the chemi-

cal and temperature resistance of pump

hoses.

DESCRIPTION

19

4.4.2 Hose compression force adjustment

The compression force on the pump hose can be

adjusted by installing a rotor with a different dimension

between the tips of the integral pressing shoes. The

rotor is chosen to achieve an optimal life of the pump

hose for the intended use of the hose pump. Two rotor

sizes are available: a low-pressure rotor and a medium

pressure rotor.

Low-pressure rotors and medium-pressure rotors can

be recognized by a marked hole near the ‘M’ for

medium-pressure (A) or ’L’ for low-pressure (B) on the

rotor.

Refer to the table for the correct rotor per required

discharge pressure.

If you want to change the application of your hose

pump, contact your Bredel representative.

4.4.3 Lubrication and cooling

The pumphead is filled with Bredel Genuine Hose

Lubricant. This lubricant lubricates the shoes and

dissipates the heat generated by the movement of the

pressing shoes against the pump hose.

The lubricant is food grade. The user is responsible to

ensure the chemical compatibility of the lubricant with

the fluid to be pumped. Refer to § 11.1.4 for the

required quantity and NSF registration.

Refer to § 7.5 for the consequences of a hose failure.

B A

Discharge pressure Rotor size

0 - 400 kPa (58 psi) Low-pressure

0 - 800 kPa (116 psi)*

* Preferably 400 - 800 kPa (58 - 116 psi)

Medium-pressure

Consult your Bredel representative for

lubrication recommendations when operat-

ing the hose pump below 2 rpm.

DESCRIPTION

20

4.5 Gearbox

The hose pump types described in this manual use

helical gearbox units. Other gearbox types are available

as option. The gearboxes are fitted with a flange

connection. The standard fasteners are bolts, but studs

and nuts are packed separately for your convenience.

Refer to § 11.3 for specifications.

Refer to the documentation supplied with the gearbox

for installation and maintenance information. In case of

doubt, consult your Bredel representative.

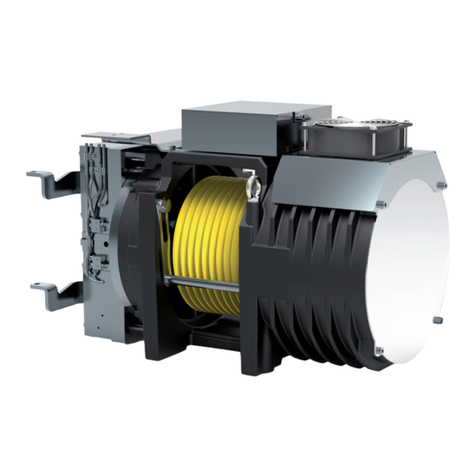

4.6 Electric motor

The standard electric motor is a completely enclosed

three-phase asynchronous motor. The motor

connection must meet the local applicable regulations.

Refer to the documentation supplied with the electric

motor for installation and maintenance information. In

case of doubt consult your Bredel representative. Refer

to § 5.3.4 and § 6.1 for installation and connection

information.

4.7 Available options

The following options are available for the hose pump:

•High level float switch

•Revolution counter

•Medium- or low-pressure rotor (depending on

the discharge pressure)

•Frequency controller1

•Three hose types

•Special configuration for use in explosive

atmospheres

1 Refer to the supplier’s documentation and § 11.5.

This manual suits for next models

2

Table of contents

Other Bredel Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Pakole

Pakole ZENIT CONDENSER Instructions for installation and servicing

LYSON

LYSON PREMIUM PC-03 instruction manual

tornos

tornos DECO 20a installation instructions

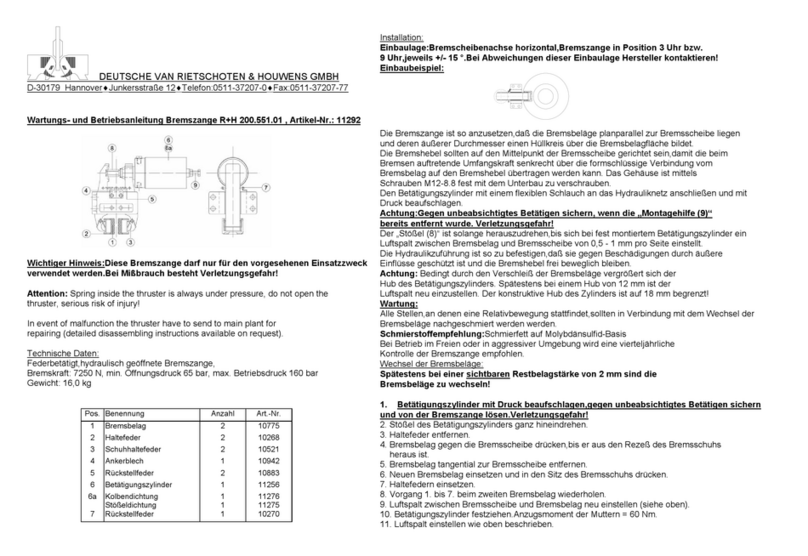

DEUTSCHE VAN RIETSCHOTEN & HOUWENS

DEUTSCHE VAN RIETSCHOTEN & HOUWENS R+H 200.551.01 Maintenance and operating manual

Hoffmann

Hoffmann GARANT VG Basic instruction manual

Mid-West Instrument

Mid-West Instrument 109 Series Installation and operating instructions