Mid-West Instrument 109 Series User manual

Mid-West

®

Instrument

Installation and Operating Instructions -

Model 109 Series

B

ulletin No: IM

1

09

/1

8

Supersedes IM109/01

F

1. Safety

Before installing verify compatibility to the process

media and temperature in contact with the wetted

parts. Incompatible media and / or operation at

temperature extremes can cause premature

degradation of materials which could result in

safety risk to personnel.

Verify the selected pressure range (differential

pressure and working pressure) are within

specification for your application.

arning! Remaining media may result in a

risk to personnel, environment etc.

Use sufficient precautionary

measures when removing and

transporting the product.

1.1

Intended use: The differential pressure gauges

are used for monitoring differential pressures in

industrial applications. The manufacturer shall not

be liable for any claims if the product is used in

applications contrary to the intended use.

1.2

Personnel: Personnel installing and putting this

instrumentation into service shall be suitably trained

and qualified in accordance with local codes,

practices and regulations.

PRODUCT DESCRIPTION

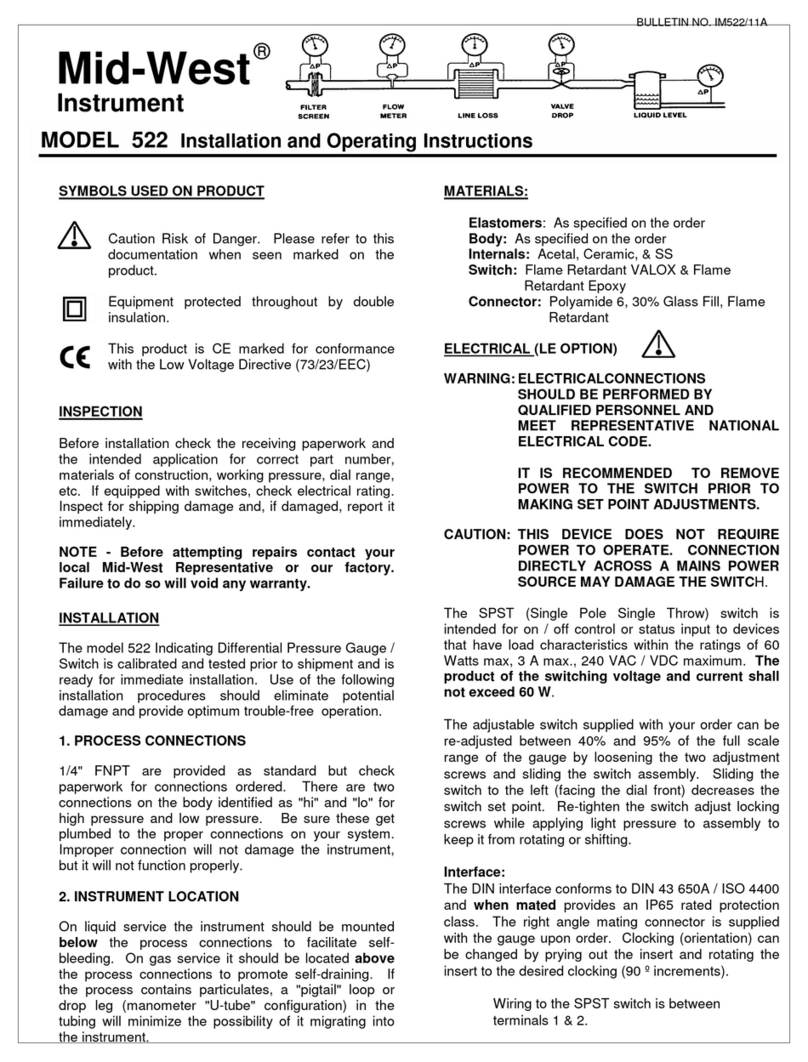

The Model 109 is a precision differential pressure

gauge capable of wor ing in systems requiring medium to

high differential pressure readout. A test quality bourdon

tube assembly is used to sense the differential pressure.

The assembly is encapsulated in a high pressure chamber

that is fitted with a pressure connection to the inside of the

bourdon tube and a second connection to the pressure

chamber.

The output shaft of the bourdon tube and gauge

movement is magnetically coupled through the solid wall

of the pressure chamber to a sensitive jeweled pointer

shaft in the dial housing outside the chamber. The

bourdon tube is protected against over-range, in either

direction, to the rated wor ing pressure by a bi-directional

relief valve.

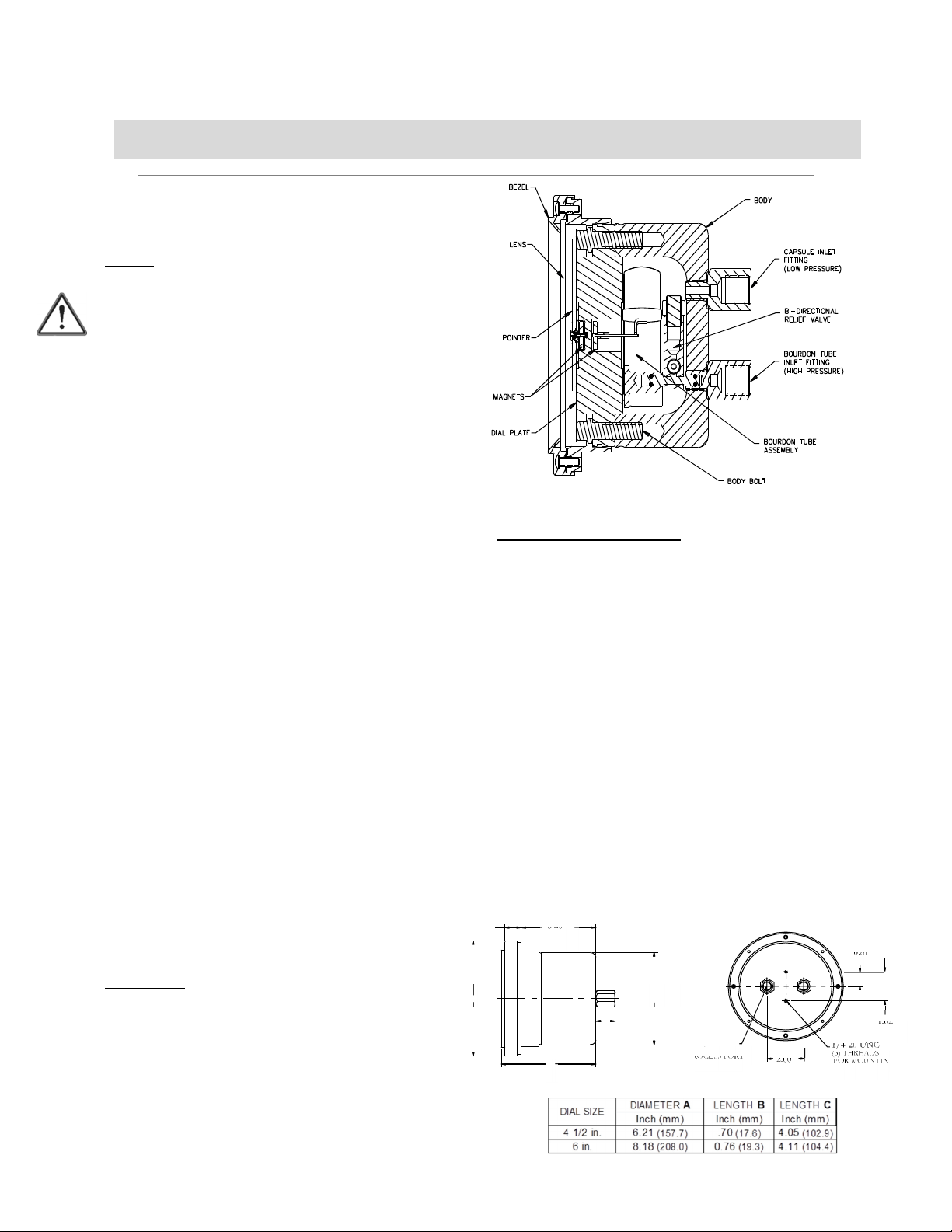

5.00

.82

3.20

[81.3 mm]

[20.9 mm]

[126.5 mm]

B

C

2.00

[50.8 mm]

1/4-20 UNC

(5) THRE DS

FOR MOUNTING

(2) PL CES

1/4 NPT

PROCESS PORT

(2) PL CES

1.62

[41.3 mm]

0.81

[20.6 mm]

HI LO

MODEL 109

LENGTH C

Installation and Operating Instructions

-

Model

1

09

Series

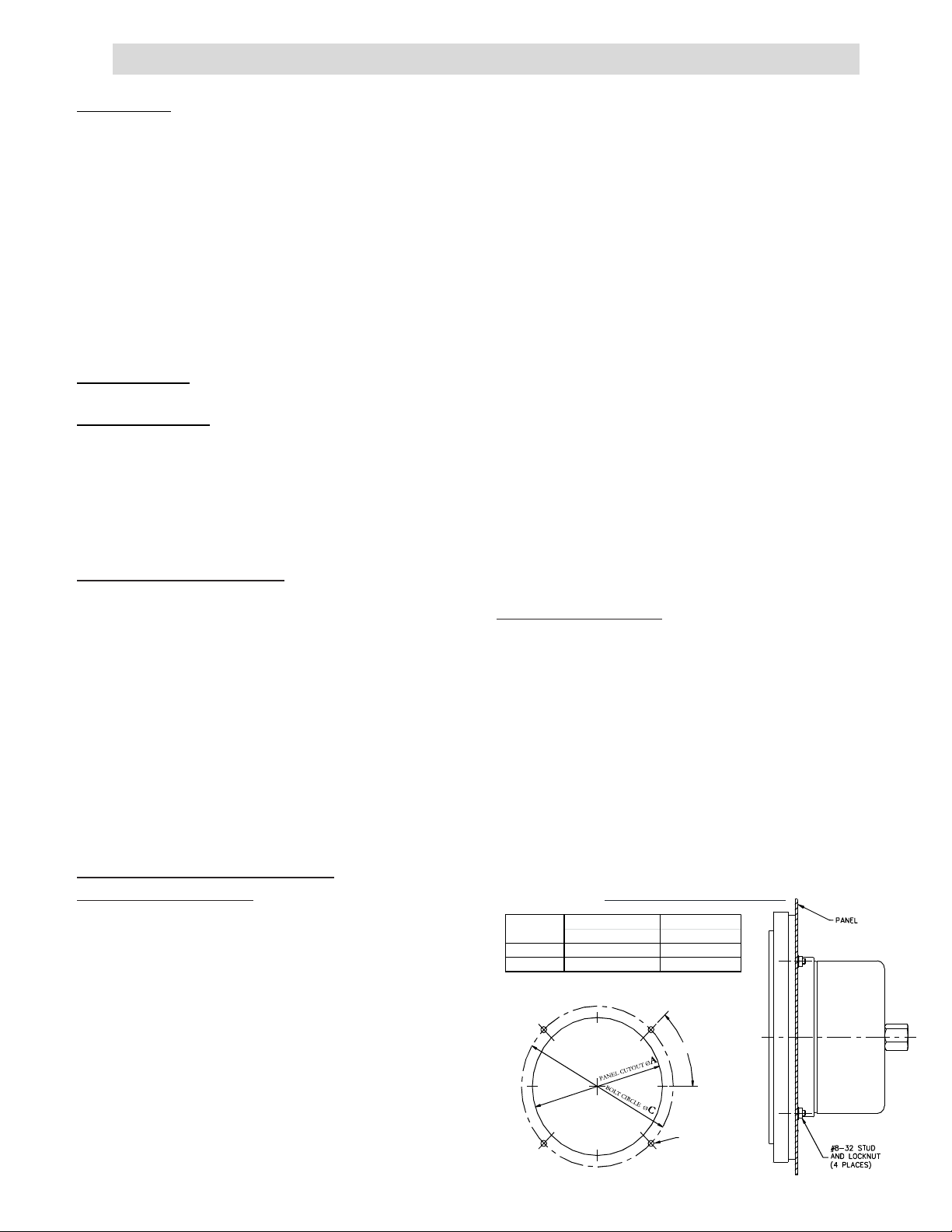

PANEL CUTOUT

A

BOLT CIRCLE

C

Inch (mm) Inch (mm)

4 1/2 in. 5.30

(134.6)

5.63

(143.0)

6 in. 6.50

(165.1)

7.00

(177.8)

DIAL SIZE

INSPECTION

Before installation chec the nameplate on each

instrument against the receiving paperwor and the

intended application for correct part number, materials of

construction, wor ing pressure, dial range, etc. If

equipped with switches, chec electrical rating, type of

enclosure, etc. Inspect for shipping damage and, if

damaged, report it immediately.

NOTE - Before attem ting re airs contact your local

Mid-West Re resentative or our factory. Failure to do

so will void any warranty.

INSTALLATION

1. CONNECTIONS

(2) ¼”FNPT pressure connections (fittings) are provided

on the bac of the gauge body as standard, but chec

paperwor for connections ordered. They are identified

as “HIGH” and “LOW” for high pressure and low

pressure. Be sure that the high gets connected to the

high and the low to the low side of your system.

2. INSTRUMENT LOCATION

On liquid service the instrument should be located below

the process connections to facilitate self-bleeding and on

gas service it should be located above the process

connections to promote self-draining. If the process

contains particulates, “pigtail” loops or drop legs

(manometer “U-tube” configuration) in the tubing will

minimize the possibility of the particulates migrating into

the instrument.

NOTE: ON LIQUID APPLICATIONS, UNEQUAL

LIQUID HEADS ON THE HIGH OR LOW SIDE

WILL RESULT IN AN INACCURATE

DIFFERENTIAL PRESSURE INDICATION.

3. INSTRUMENT INSTALLATION

RECOMMENDATIONS

Model 109 is calibrated and tested prior to shipment and

is ready for immediate installation. Use of the following

installation procedures should eliminate potential

damage and provide optimum trouble-free operation.

Rapid pressurization can cause severe damage to the

sensing element in pressure instruments. Rapid pressure

change (either increase or decrease) can be described as

a change in pressure occurring fast enough to drive an

instrument full scale in less than one second.

Most better quality instruments have over-range

protection built-in but they are mechanical in design and

cannot be relied upon to react in time to protect the

instrument against a rapid change in pressure.

The simplest method to avoid this problem is by

installation and proper use of a 3-valve manifold. Open

the equalizer valve prior to opening one or both of the

bloc valves to insure pressure is applied simultaneously

to both sides of the sensing element.

If a 3-valve manifold is not used, protection can be

provided by installation of Mid-West Model 150

snubbers to both sides of the instrument. This unit

provides an infinitely adjustable cho e valve and an

excess flow ball chec . The ball chec is designed not to

shut off completely but will restrict flow during sudden

changes in pressure while bleeding pressure to the

instrument, preventing sudden surges from being

transmitted to the instrument.

Refer any questions regarding these recommended

procedures to the local Mid-West representative in

your area or our factory in Sterling Heights, Michigan,

U.S.A.

4. PANEL MOUNTING

The Model 109 is designed for mounting through the

front of the instrument panel and is normally

provided with a panel mounting it. The it consists

of (4) panel mounting studs and nuts.

Ma e the cutouts as indicated in (Fig. 1). Insert the

(4) panel mounting studs, finger tight, into the metal

inserts located in the rear of the bezel.

Insert the gauge through the panel, aligning the

panel mounting studs with the holes in the panel.

Install the #8-32 nuts onto the studs and tighten

securely.

MODEL 109 PANEL CUT-OUT

DIMENSIONS

Ø 0.19 (4.7)

(4 HOLES)

45°

Installation and Operating Instructions

-

Model

1

09

Series

5. PIPE MOUNTING

If specified, your Model 109 will have a pipe mounting it

installed. This provides for mounting on a 2” vertical or

horizontal pipe. See below for details.

6. WALL MOUNTING

If specified, your Model 109 will have a wall mounting it

installed. This provides for mounting on a panel or wall.

See below for details.

TROUBLE

SHOOTING

1. Gauge does not indicate differential

A. Chec for proper hoo up, high to “HIGH” and

low to “LOW”

B. Ma e certain bloc valves are open and, if using

a 3-valve manifold, that the equalizer (balance)

valve is closed.

C. If A & B chec out correctly, loosen or

disconnect the high pressure line to determine if

there is pressure to the instrument.

D. If there is pressure to the instrument, chec to

determine that there is differential across the

unit being monitored. If so, contact the factory

for assistance and/or an “RGA” (return goods

authorization) number to return the instrument

for repair or replacement

2. Indicating ointer off zero. (With block valves

closed, or no system differential)

A. Tap gauge lightly.

B. Make certain block valves are closed and

equalizer valve is open.

C. If A & B do not correct the “off zero”

condition, remove the bezel and lens

assembly by removing the (4) bezel

screws. Slightly loosen the “phillips head”

screw, located in a slot in the dial, in the

lower left dial area at about “7:30”. Rotate

the dial until “zero” is under the pointer by

use of any pointed object inserted in one

of the small notches in the top and bottom

of the dial. Retighten the “phillips head”

screw and reinstall the bezel and lens

assembly.

Recalibration and/or Re air

1. If recalibration or repair is required, secure an

“RGA” (returned goods authorization) number

from Mid- West Instrument and return instrument

to the factory.

2. If (1) is not practical we recommend you discuss

your problem with one of our customer service

representatives and request a “technical service”

manual. Please have both the model and serial

numbers available before calling.

2 INCH PIPE MOUNT (FOR

VERTIC L OR HORIZONT L PIPE)

Other Mid-West Instrument Industrial Equipment manuals