2

Table of contents

1 General Information........................................................................................................................ 3

1.1 Introduction............................................................................................................................. 3

1.2 Use of the reducer................................................................................................................... 3

1.3 Terminology and types of alerts.............................................................................................. 3

2 Safety instructions........................................................................................................................... 4

2.1 General inustrctions................................................................................................................ 4

2.2 Installation of the reducer....................................................................................................... 4

2.3 Operation of the reducer ........................................................................................................ 5

2.4 Disposal ................................................................................................................................... 6

2.5 EU Directive 2006/42/EC......................................................................................................... 6

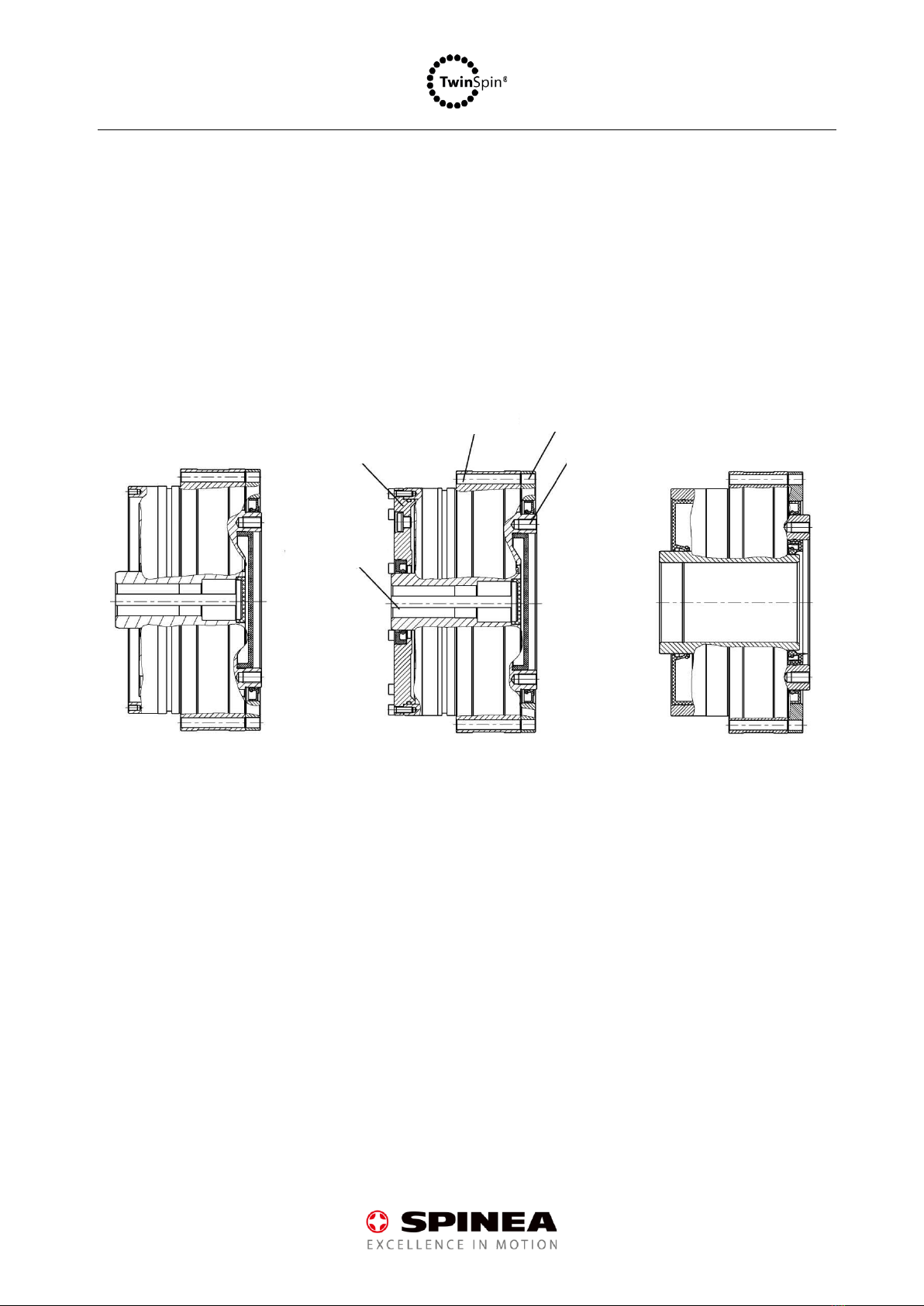

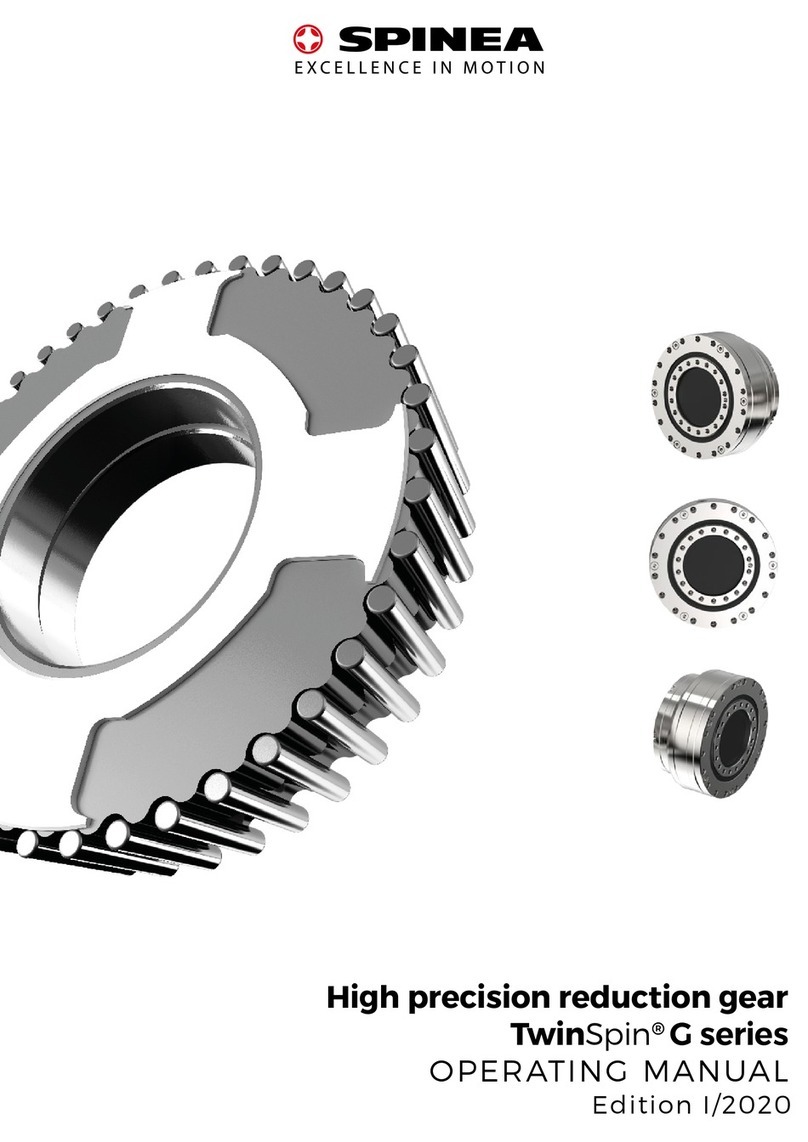

3 Product Description......................................................................................................................... 7

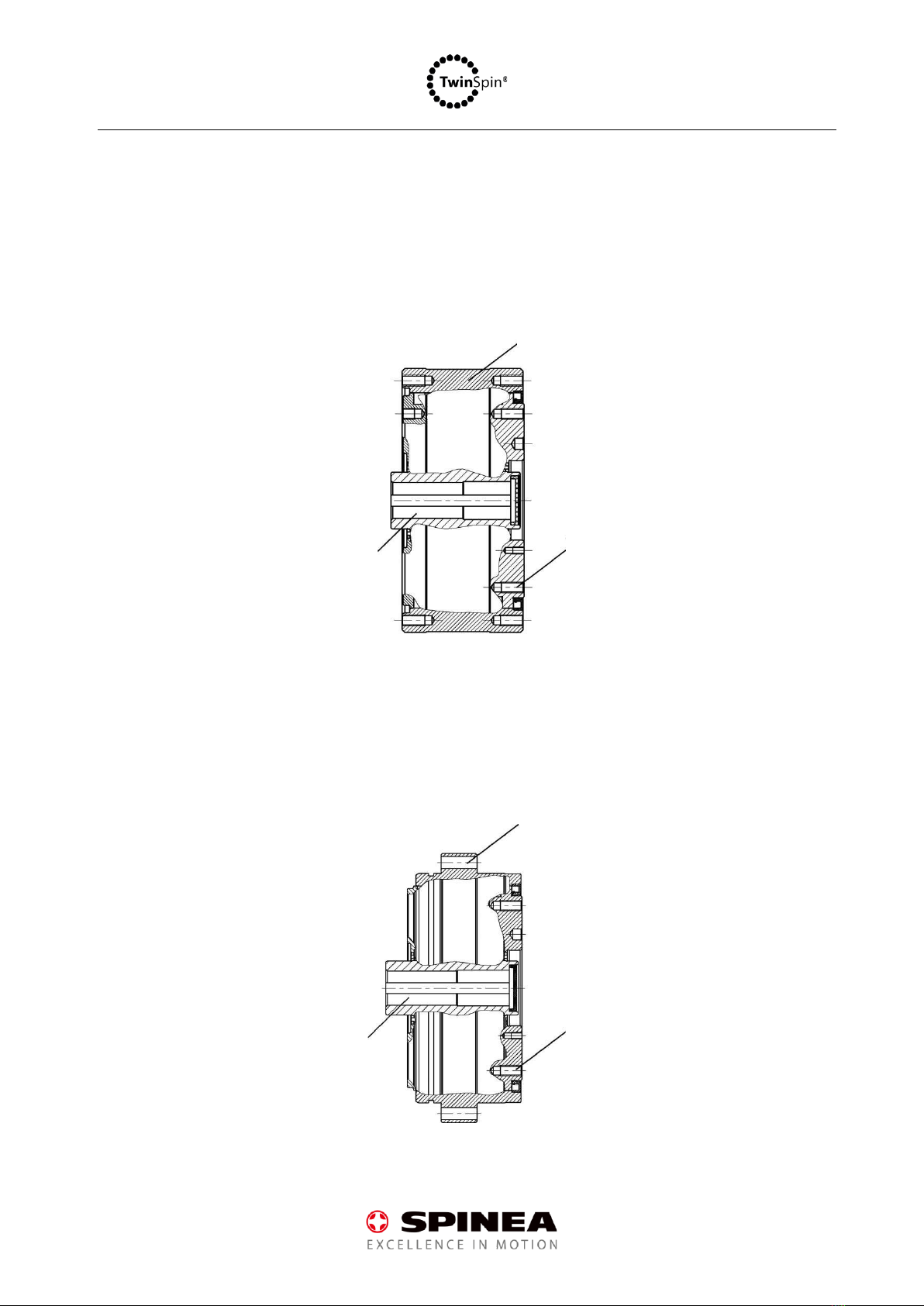

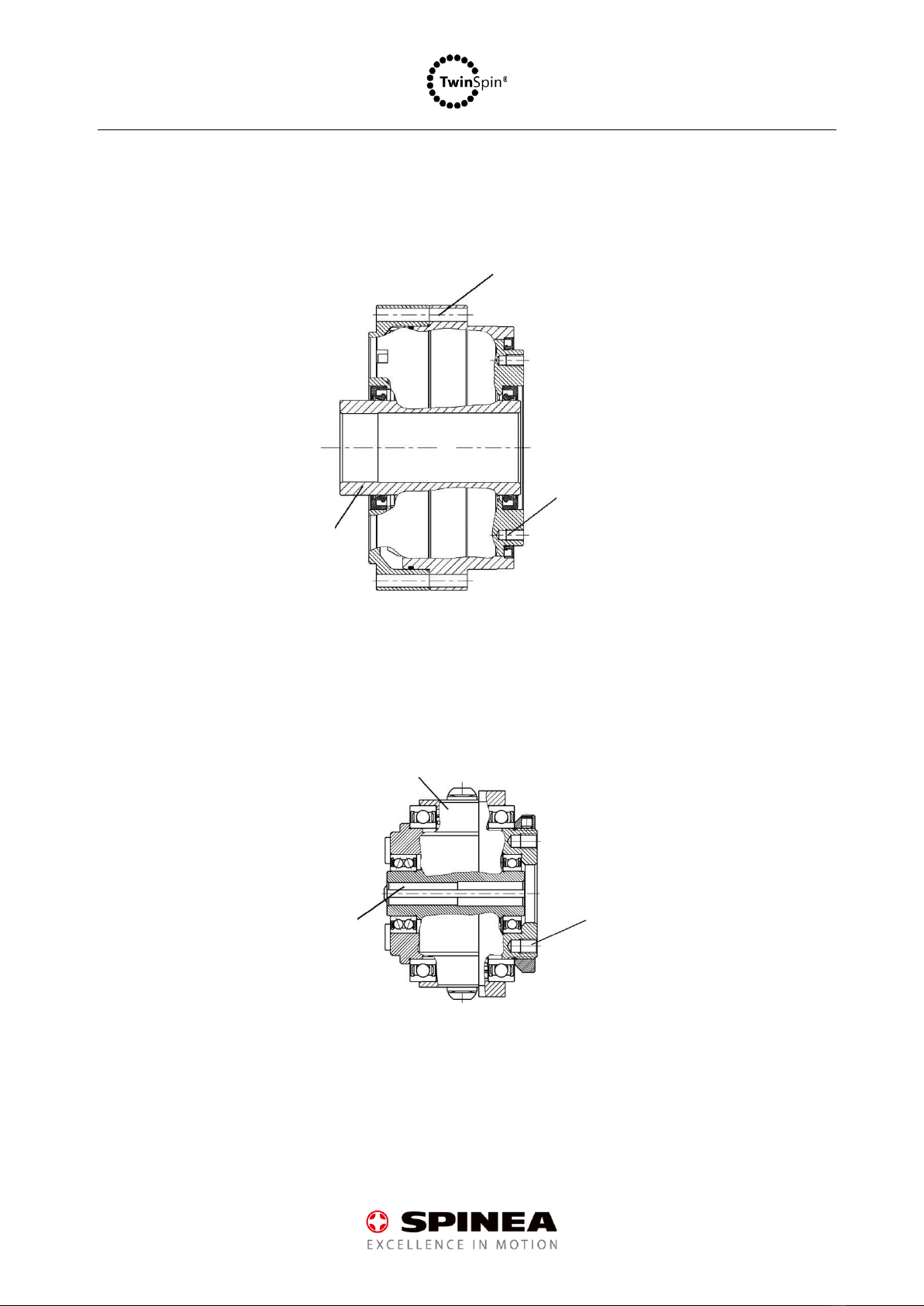

3.1 Reducer versions ..................................................................................................................... 7

4 Chapter Mounting Reducers in Applications................................................................................. 10

4.1 Motor flanges........................................................................................................................ 10

4.2 Bolts and tightening torque for mounting reducers............................................................. 11

4.3 Sealing components for sealed reducers .............................................................................. 13

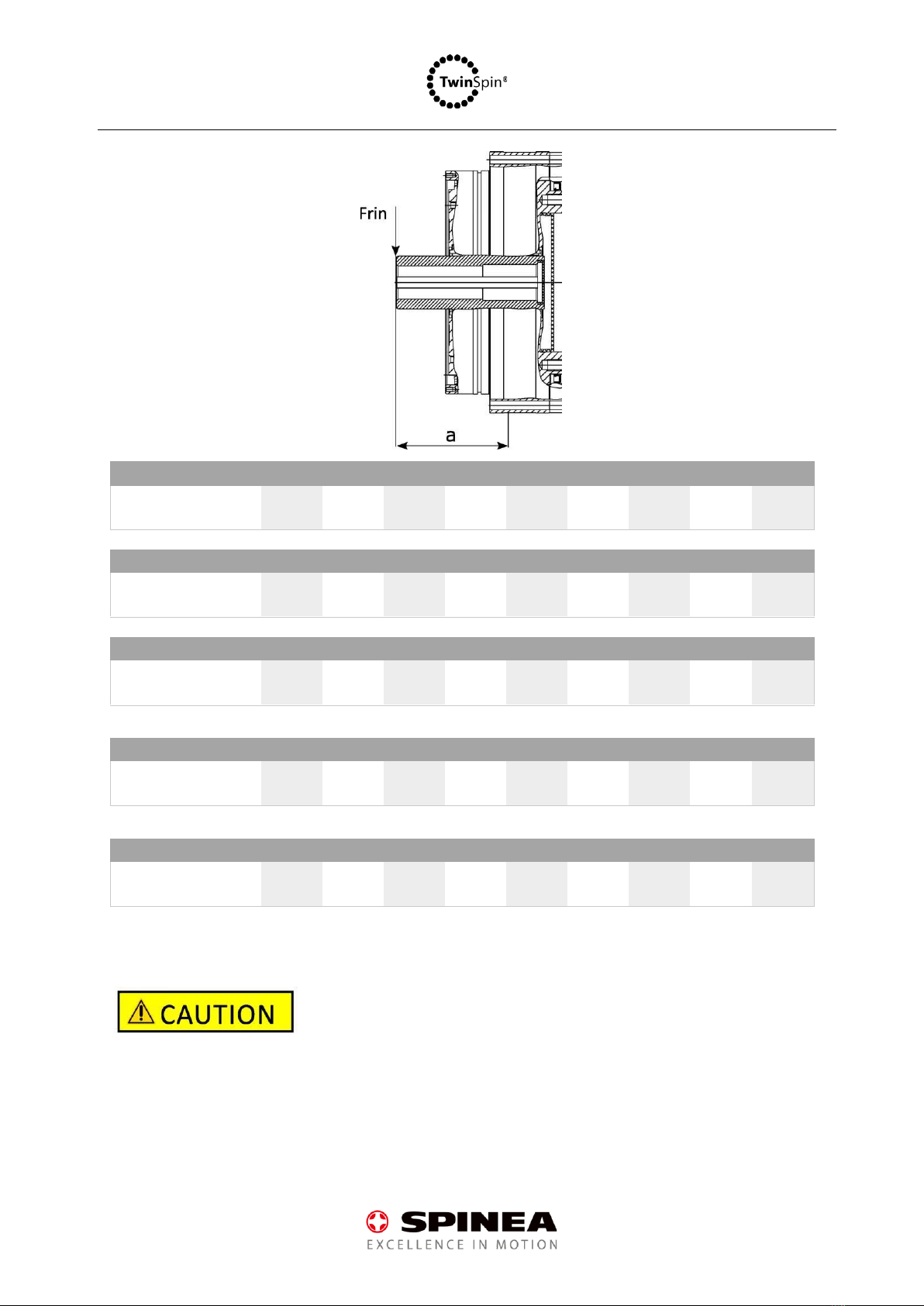

4.4 Permissible input shaft load.................................................................................................. 13

4.5 Installation of TwinSpin reducers.......................................................................................... 14

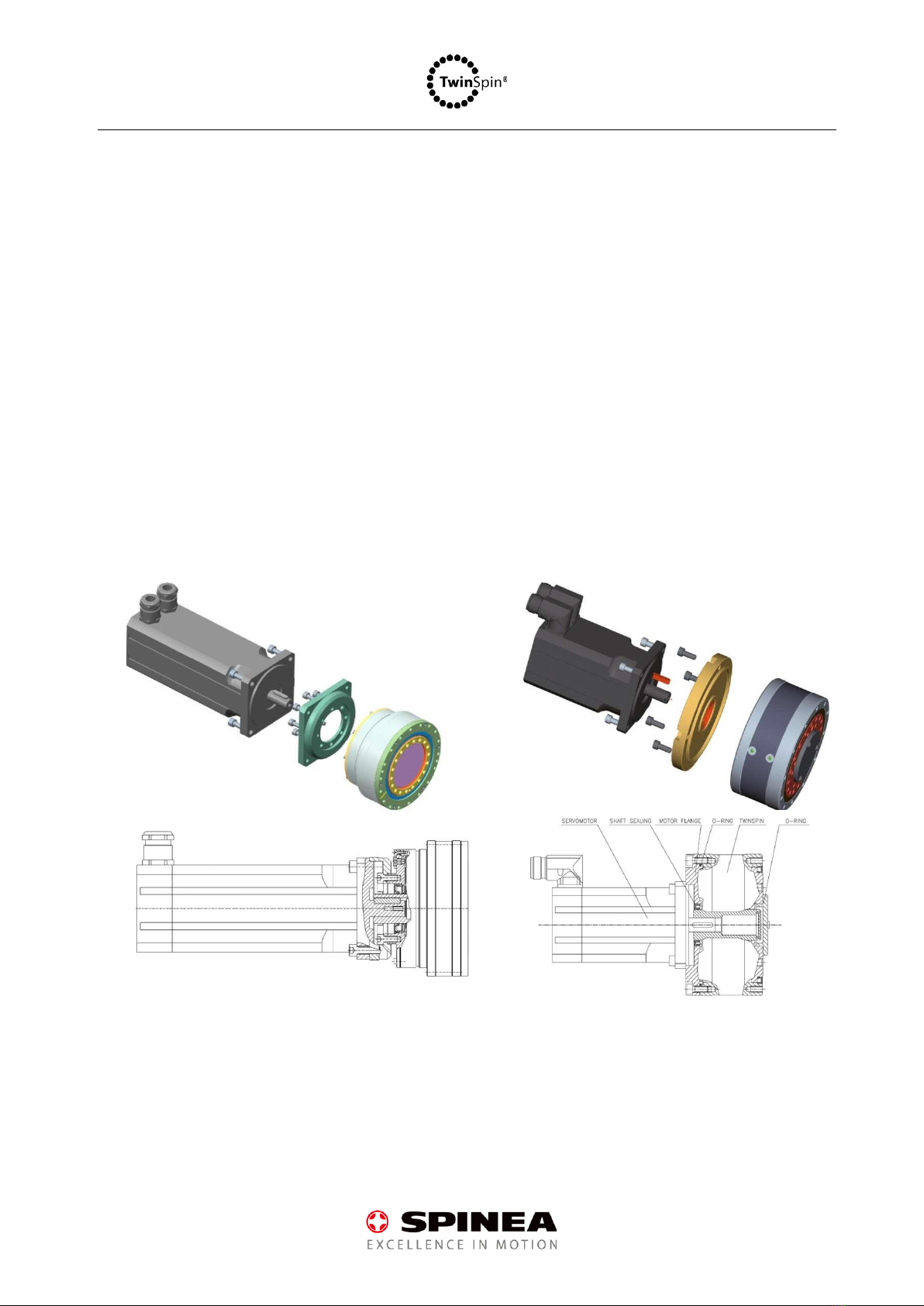

4.5.1 Assembly with direct connection to the motor with the keyway..................................... 16

4.5.2 Mounting with adapter (splined or keyway) with smooth shaft motor ........................... 17

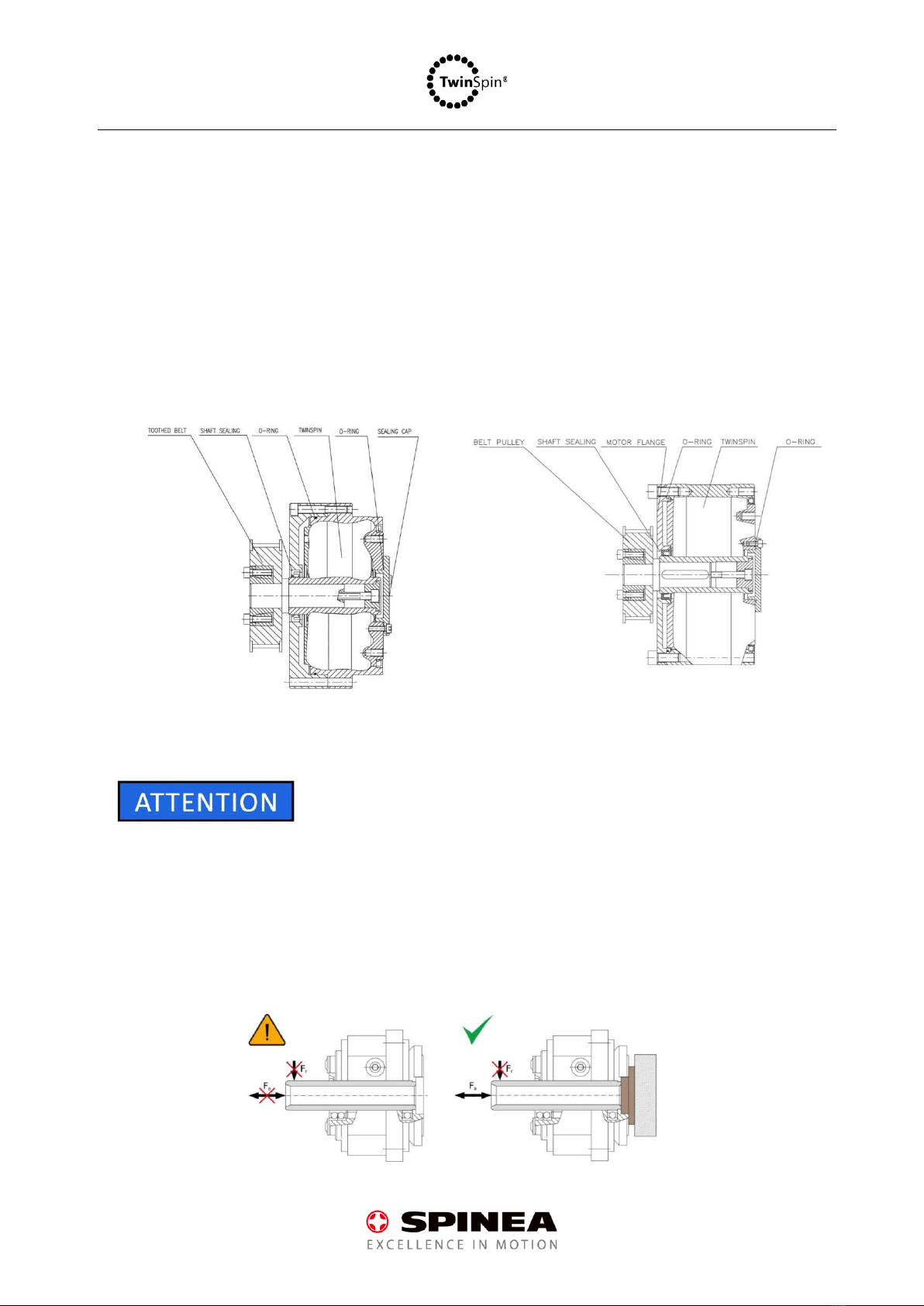

4.5.3 Assembly with coupling..................................................................................................... 18

4.5.4 Mounting with pulley ........................................................................................................ 19

4.5.5 Specific installation warnings............................................................................................ 19

5 Lubrication of reducers ................................................................................................................. 20

6 Storage and transport ................................................................................................................... 21

7 Warranty ....................................................................................................................................... 21

8 Operation of reducers................................................................................................................... 22

9 Labelling of reducers ..................................................................................................................... 23

10 Service ....................................................................................................................................... 23