Bredenoord ESaver III User manual

© Bredenoord Aggregaten 2013

Complete operation manual

ESaver III

HAH0003 - HAH0012

15 kVA

Controller type: Mitsubishi PLC

Bredenoord Aggregaten BV - Zutphensestraat 319, 7325 WT Apeldoorn - Postbus 20122, 7302 HC Apeldoorn

|www.bredenoord.com

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 2

Content

1................................................................................................................................... 3

Safety measures and symbols

................................................................................................................................... 31.1 Safety markings in the text

................................................................................................................................... 31.2 Safety instructions

................................................................................................................................... 31.3 Safety symbols on the ESaver

................................................................................................................................... 41.4 Switching safe

2................................................................................................................................... 5

Protections ................................................................................................................................... 52.1 Control circuit protections

................................................................................................................................... 52.2 Emergency stop

3................................................................................................................................... 6

Installation of the ESaver

4................................................................................................................................... 7

Connection of the ESaver

................................................................................................................................... 74.1 Electrical connections

................................................................................................................................... 74.2 Connecting power cables

5................................................................................................................................... 8

Operating instructions

................................................................................................................................... 85.1 Starting and stopping

................................................................................................................................... 95.2 Testing diesel genset

6................................................................................................................................... 10

Reading data

7................................................................................................................................... 11

Construction

8................................................................................................................................... 12

Timer

9................................................................................................................................... 14

Software ................................................................................................................................... 149.1 User ................................................................................................................................... 169.2 Service

10 ................................................................................................................................... 18

Trouble-shooting

11 ................................................................................................................................... 20

Moving the ESaver

12 ................................................................................................................................... 21

Maintenance

................................................................................................................................... 2112.1 Important points for maintenance

................................................................................................................................... 2212.2 Servicing

13 ................................................................................................................................... 23

Expiring of the warranty

14 ................................................................................................................................... 24

Technical data

............................................................................................................................................. 25EC-Declaration of Conformity IIA

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 3

1 Safety measures and symbols

Every other use of the ESaver than that described in this user manual, can lead to a dangerous working

situation, both for the ESaver and user(s). Bredenoord Aggregaten BV refuses to accept responsibility for any

claim of damage or human harm which has occurred because of not following the instructions in this manual or

by lack of care during use, installation, service, maintenance or repair of the ESaver. It is necessary, before

usage, to read this user manual with care. Always followthe safety instructions! For information regarding

installation, maintenance or repair not included in this manual, please contact Bredenoord Aggregaten BV.

1.1 Safety markings in the text

The safety markings in the text have the following meaning:

BEWARE!

If a comment has additional information, it’s drawing your attention to possible problems or dangers.

WARNING!

Indicates that you can (seriously) injure yourself if you do not carry out the procedures with care.

DANGER!

Indicates that your life is directly threatened if you do not carry out the procedures with care.

1.2 Safety instructions

Only start the machine when all safety measures have been observed.

The ESaver is only permitted to be operated, serviced, maintained and connected by qualified and

adequately trained personnel that is authorized by the customer.

No maintenance, connection, commissioning, usage or other operation before consulting the manual.

Switch the ESaver safe before carrying out maintenance, repairs or other jobs.

Operate the generator only when all protective parts have been correctly installed (again).

Watch out for parts that are under voltage in the electric switchboard cabinets.

Only use the ESaver when the emergency stop is visible and accessible.

Keep the doors of the room and/or ESaver closed during operation because of cooling, noise and entry.

Keep open fires and other combustible elements away from the generator. Also don´t install the ESaver

nearby flammable gasses.

Keep a powder fire extinguisher in the direct proximity of the ESaver.

Be careful with batteries, very high currents will run when short-circuited.

Apply appropriate (personal) safety measures when servicing the ESaver.

Do not use the ESaver if your concentration is diminished for example by tiredness or alcohol

consumption.

The ESaver is exclusively intended for use as (emergency) power supply. All other usage is seen as

unintended use by the manufacturer and is therefore forbidden.

1.3 Safety symbols on the ESaver

In the ESaver are protective measures mounted for electrical parts. When this is not possible due to practical

reasons, warning stickers have been placed. To warn for dangerous situations the following safety symbols can

be used on the ESaver:

Danger! You are close to a life-threatening voltage!

Emergency stop!

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 4

Danger of burns! Hot parts

Beware! This machine can start automatically!

Beware: ventilator

This sticker refers to this manual:

BEWARE!

It is not permitted to make adjustments in the control panel other than by a qualified electrician. In

all other cases only allow the installation to be adjusted by an employee of Bredenoord Aggregaten.

When you make adjustments yourself or have adjustments made, the firm Bredenoord Aggregaten

B.V. is not in any way responsible for possible damage as a result of incorrect installation of the

ESaver.

1.4 Switching safe

Before working on the ESaver, the ESaver first has to be switched safe. The procedure for making an electric

installation voltage free depends on the installation, for this please contact the owner of the installation.

The ESaver is only permitted to be operated, serviced, maintained and connected by qualified and

adequately trained personnel that are authorized by the customer.

Always switch the ESaver safe when you want to work on the ESaver.

To prevent the ESaver from (automatically) starting the following should be done.

Make sure the ESaver isn´t running and switch off the controls.

When you work on or near electric conductors always check that these are not under voltage,

according to the applicable electrical requirements. After this also check the used meter for correct

functioning. With emergency generators also take account of possible voltage from the grid.

Always place warning signs and/or padlocks so that no one will start the ESaver while you´re working

on it. Provide a safety zone around the machine of about 3 meters to block entry of third parties and

unauthorized persons.

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 5

2 Protections

To ensure safety of personnel and machine, various protections are installed on the ESaver.

2.1 Control circuit protections

The panels contain fuses and circuit breakers for the control circuits. The name and function of the breakers

can be found on the cable ducts and in the electrical schematics. For correct operation, all of the breakers in

the control panel should be ON.

There can be dangerous voltages in the electric panels. When a breaker or fuse must be switched,

it should be done by qualified personnel.

2.2 Emergency stop

An emergency stop is mounted on the control panel or on the outside of the housing.

This switches off the machine during an emergency situation. After using the emergency

stop button, the inverters will be directly switched off and the engine will stop.

Before restarting the following procedure has to be succeeded.

Reset the emergency stop by turning it counterclockwise.

Reset the alarm on the control panel.

Start the ESaver.

The emergency stop on the outside can be covered with a lid. The risk that exists while covering the

emergency stop should be considered carefully.

The emergency stop only switches off the ESaver! A connected genset is not switched off.

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 6

3 Installation of the ESaver

Keep the following points in mind while installing the ESaver:

Place the ESaver preferably in open air for optimal ventilation. Ensure there is enough free space around

the air inlet and outlet of the ESaver.

Do not place the ESaver against buildings or walls. Ensure there is enough free space to open the doors.

The ESaver must be placed on a flat, strong and horizontal surface.

When placing the ESaver indoors the following instructions also apply:

Ensure that there is enough free (movement) space around the ESaver.

Ensure enough space on both sides of the ESaver for inlet and outlet of the cooling air.

Ensure that there is enough ventilation and a good temperature control in the room where the ESaver is

placed. The ESaver produces heat during use.

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 7

4 Connection of the ESaver

This chapter describes how the power cables have to be connected.

4.1 Electrical connections

When using a genset with the ESaver it should be attempted to connect the installation according to the TN

system. For more information about earthing please consult the national applicable standards and regulations.

Below a schematic of a TN system is shown.

In the schematic is shown that the neutral and earth connection of the generator are directly earthed. When no

earthing is available this is done by placing an earth pin.

The connection of the ESaver should be done by a certified installation company.

Only connect the ESaver when it´s switched safely.

The ESaver provides electricity with a clockwise rotation field by means of 3 phase connection: L1, L2, L3 and

N. Connect the load(s) according to EN-50110 and keep the following points in mind during connection:

Only connect approved cables to the ESaver.

Only attach cables via the cable input. The door should be closed during operation.

4.2 Connecting power cables

The ESaver works only with a clockwise rotation field!

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 8

5 Operating instructions

This chapter discusses the operating instructions of the ESaver.

Always follow the maintenance instructions, which can be found in the maintenance chapter of this manual,

before use.

The ESaver is only permitted to be operated by qualified and adequately trained personnel that is

authorized by the customer.

Take care that the maximum load to switch does not exceed the maximum step load of the ESaver!

(see technical data)

5.1 Starting and stopping

Starting

Ensure that the diesel genset can automatically start by means of the connector (5)

(see operation manual diesel genset or start-stop module)

Turn the selector switch (1) to “ON”

Press the button "START" (2). The ESaver starts!

Switch on the main switch (4)

Stopping

Switch off the main switch (4)

Press the button "STOP" (3). The ESaver stops!

Turn the selector switch (1) to “OFF”

Alarm reset

Turn the selector switch (1) to “OFF”

Turn the selector switch (1) to “ON”

Press the button "START" (2). The ESaver starts!

Switch on the main switch (4)

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 9

5.2 Testing diesel genset

Turn the selector switch (1) to “ON”

Start the ESaver

Press the arrow buttons, so that screen D appears

Press the button "START" (2)

Screen E appears ("Controle laden even geduld")

If the diesel genset is working properly, screen F appears ("Koppeling aggregaat OK")

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 10

6 Reading data

Turn the selector switch (A) to “ON”

1. Touch screen (see below)

2. Battery monitor

Press the arrow buttons (B) so that the screens - indicated below - appears.

Screen with alarms

3. Power genset

4. Status ESaver

5. Power user

6. Battery status

7. Alarms

8. Timer genset

9. Running hours ESaver

10.Running hours genset

11.Charge cycles battery

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 11

7 Construction

Front

Back

1. Selector switch

2. Touch screen

3. Battery monitor

4. Emergency stop

5. Inverters

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 12

8 Timer

Timer for genset

1. Switch on/switch off timer

2. Switch on genset manually, works only when inverters and timer are switched on

3. Switch off genset manually

4. Set clock

5. Switch on point or switch off point

6. Adjust switch time (hours), press the hour indication

7. Adjust switch time (minutes), press the minute indication

Normal functioning timer:

At the switch on point (example 8:00 hour) the diesel genset starts. At the switch off point (example

21:00 hour) the diesel genset stops.

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 13

Manually starting with button 2, for example if the work once begins earlier or if the settings of the timer are

modified:

The diesel genset starts manually. At the switch off point (example 21:00 hour) the diesel genset

stops.

Manually stopping with button 3, for example if the work once stops earlier or if the settings of the timer are

modified:

At the switch on point (example 8:00 hour) the diesel genset starts. Then the diesel genset stops

manually. On the next switch on point the diesel genset starts again.

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 14

9 Software

This chapter discusses the menu structure.

9.1 User

A.Status ESaver (see also next page)

B.Status genset

C.Status user

D.Status battery

E.Start/stop ESaver

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 15

A.Status ESaver

B.History ESaver

C.History battery

D.Status ESaver

E.Timer for genset

F. Test diesel genset (works only in this service screen)

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 16

9.2 Service

A.Test diesel genset (works only in this service

screen)

B.Input password

C.Service options

1. Start/stop ESaver

2. Charge batteries to 95%

3. Charge batteries to 100%

D.Status ESaver (see also next page)

E.Statistics

F. Settings controller

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 17

A.Status ESaver

B.Reset data

C.Set clock

D.Settings main menu

E.Settings screen

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 18

10 Trouble-shooting

Following diagnosis of the fault deals with general causes and is valid for most applications. For all faults the

handbook of the inverters should be consulted in the first place.

FAILURE INDICATION

POSSIBLE CAUSE

SOLUTION

Inverter will not switch over to

generator or mains operation

Circuit breaker or fuse in the AC-in

input is open as a result of overload

Remove overload or short circuit on AC-out-1

or ACout-2, and reset fuse/breaker

Inverter operation not initiated

when switched on

The battery voltage is excessively

high or too low. No voltage on DC

connection

Ensure that the battery voltage is within the

correct range

“Low battery” LED flashes

The battery voltage is low

Charge the battery or check the battery

connections

“Low battery” LED lights

The converter switches off because

the battery voltage is too low

Charge the battery or check the battery

connections

“Overload” LED flashes

The converter load is higher than

the nominal load

Reduce the load

“Overload” LED lights

The converter is switched off due to

excessively high load

Reduce the load

“Temperature” LED flashes or

lights

The environmental temperature is

high, or the load is too high

Install the converter in cool and well-ventilated

environment, or reduce the load

“Low battery” and “overload” LEDs

flash intermittently

Low battery voltage and excessively

high load

Charge the batteries, disconnect or reduce the

load, or install higher capacity batteries. Fit

shorter and/or thicker battery cables

“Low battery” and “overload” LEDs

flash simultaneously

Ripple voltage on the DC connection

exceeds 1,5Vrms

Check the battery cables and battery

connections. Check whether battery capacity

is sufficiently high, and increase this if

necessary

“Low battery” and “overload” LEDs

light

The inverter is switched off due to an

excessively high ripple voltage on

the input

Install batteries with a larger capacity. Fit

shorter and/or thicker battery cables, and

reset the inverter (switch off, and then on

again)

One alarm LED lights and the

second flashes

The inverter is switched off due to

alarm activation by the lighted LED.

The flashing LED indicates that the

inverter was about to switch off due

to the related alarm

Check this table for appropriate measures in

regard to this alarm state

The charger does not operate

The AC input voltage or frequency

is not within the range set

Ensure that the AC input is between 185

VAC and 265 VAC, and that the frequency

is within the range set (default setting 45-

65Hz)

Circuit breaker or fuse in the AC-

in input is open as a result of

overload

Remove overload or short circuit on AC-out-

1 or ACout-2, and reset fuse/breaker

The battery fuse has blown

Replace the battery fuse

The distortion or the AC input

voltage is too large (generally

generator supply)

Turn the settings WeakAC and dynamic

current limiter on

The charger does not operate.

“Bulk” LED flashes and “Mains on”

LED illuminates

MultiPlus is in “Bulk protection”

mode thus, the maximum bulk

charging time of 10 hours is

exceeded. Such a long charging

Check your batteries.

NOTE: You can reset the error mode by

switching off and back on the MultiPlus. The

standard MultiPlus factory setting of the “Bulk

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 19

FAILURE INDICATION

POSSIBLE CAUSE

SOLUTION

time could indicate a system error

(e.g. a battery cell short-circuit)

protection” mode is switched on. The “Bulk

protection” mode can be switched off with help

of VEConfigure only

The battery is not completely

charged

Charging current excessively high,

causing premature absorption

phase

Set the charging current to a level between

0.1 and 0.2 times the battery capacity

Poor battery connection

Check the battery connections

The absorption voltage has been

set to an incorrect level (too low)

Set the absorption voltage to the correct

level

The float voltage has been set to

an incorrect level (too low)

Set the float voltage to the correct level

The available charging time is too

short to fully charge the battery

Select a longer charging time or higher

charging current

The absorption time is too short.

For adaptive charging this can be

caused by an extremely high

charging current with respect to

battery capacity, so that bulk time

is insufficient

Reduce the charging current or select the

‘fixed’ charging characteristics

The battery is overcharged

The absorption voltage is set to an

incorrect level (too high)

Set the absorption voltage to the correct

level

The float voltage is set to an

incorrect level (too high)

Set the float voltage to the correct level

Poor battery condition

Replace the battery

The battery temperature is too

high (due to poor ventilation,

excessively high environmental

temperature, or excessively high

charging current)

Improve ventilation, install batteries in a

cooler environment, reduce the charging

current, and connect the temperature

sensor

The charging current drops to

0 as soon as the absorption

phase initiates

The battery is over-heated (>50°C)

- Install the battery in a cooler environment

- Reduce the charging current

- Check whether one of the battery cells has

an internal short circuit

Defective battery temperature

sensor

Disconnect the temperature sensor plug in

the inverter. If charging functions correctly

after approximately 1 minute, the

temperature sensor should be replaced

Should you experience an error that is not listed above and/or in the documentation of the inverters please

contact the service department of Bredenoord.

Complete operation manual version 2.4.0

© Bredenoord Aggregaten 2013 20

11 Moving the ESaver

The ESaver is equipped with a lifting eye and forklift beams. Check before moving if customer cables are

disconnected, that all doors are closed and the ESaver can be moved safely.

Never move under the lifted ESaver! Never work on the lifted ESaver!

Always check if the crane or forklift is suitable to lift the weight. The weight of the ESaver can be

found in the technical data of this manual.

Moving by means of the lifting eye (if applicable)

The ESaver can be lifted by means of the lifting eye with a chain and a suitable crane. Never attach the chain

directly to the lifting eye due to damage but use a closable hook.

Lifting eye (if applicable)

Use only approved lifting equipment and check the lifting eye and lifting equipment for damage.

Moving by means of a forklift

When moving the ESaver by means of a forklift it’s important to keep the ESaver as straight as possible to

prevent falling from the lifting forks.

Keep in mind during lifting that the centre of gravity of the ESaver lies beneath the lifting eye.

Other manuals for ESaver III

3

This manual suits for next models

2

Table of contents

Other Bredenoord Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

AutomationDirect

AutomationDirect CLICK PLUS C2-03CPU quick start guide

Tracer

Tracer Optimus T221 Operation manual

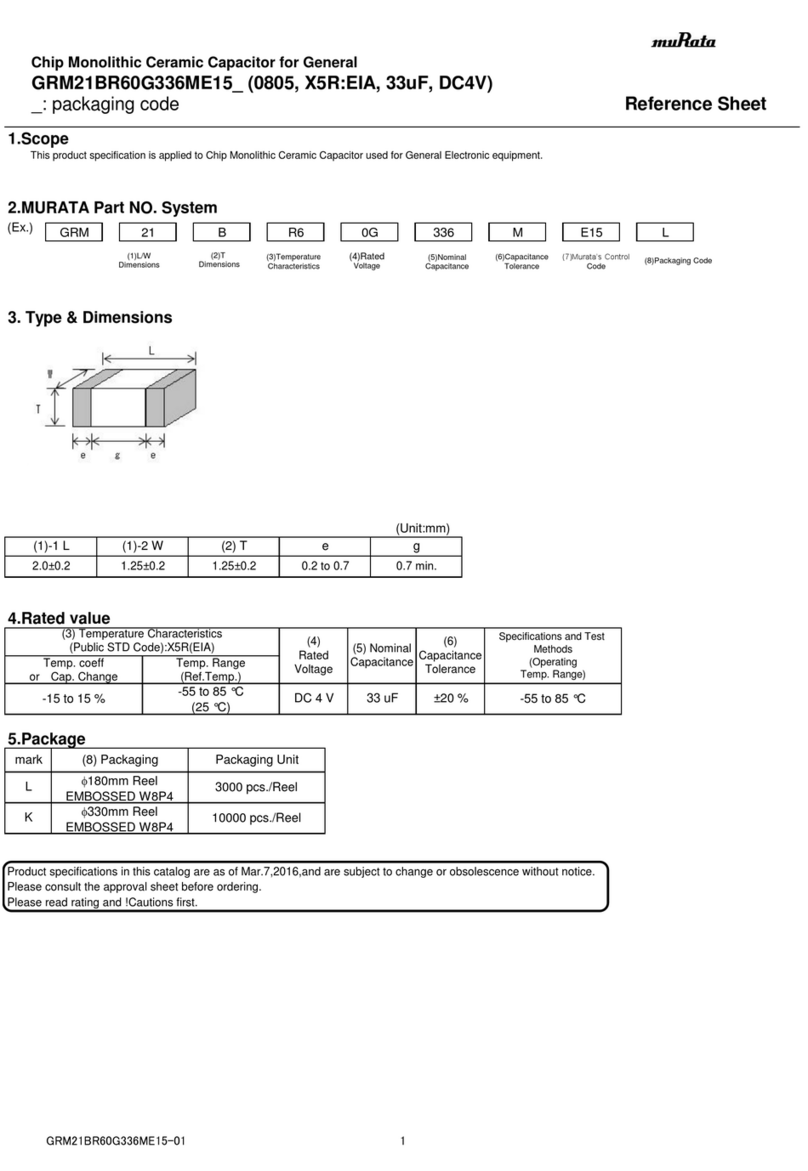

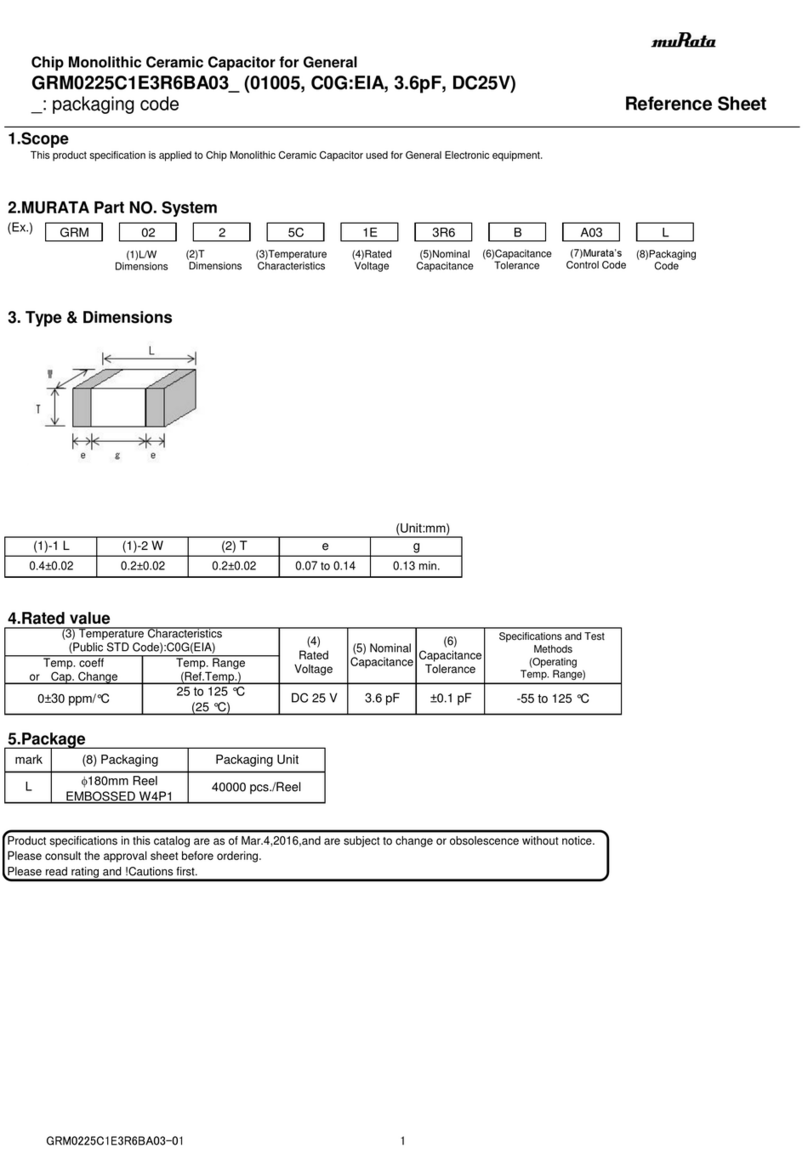

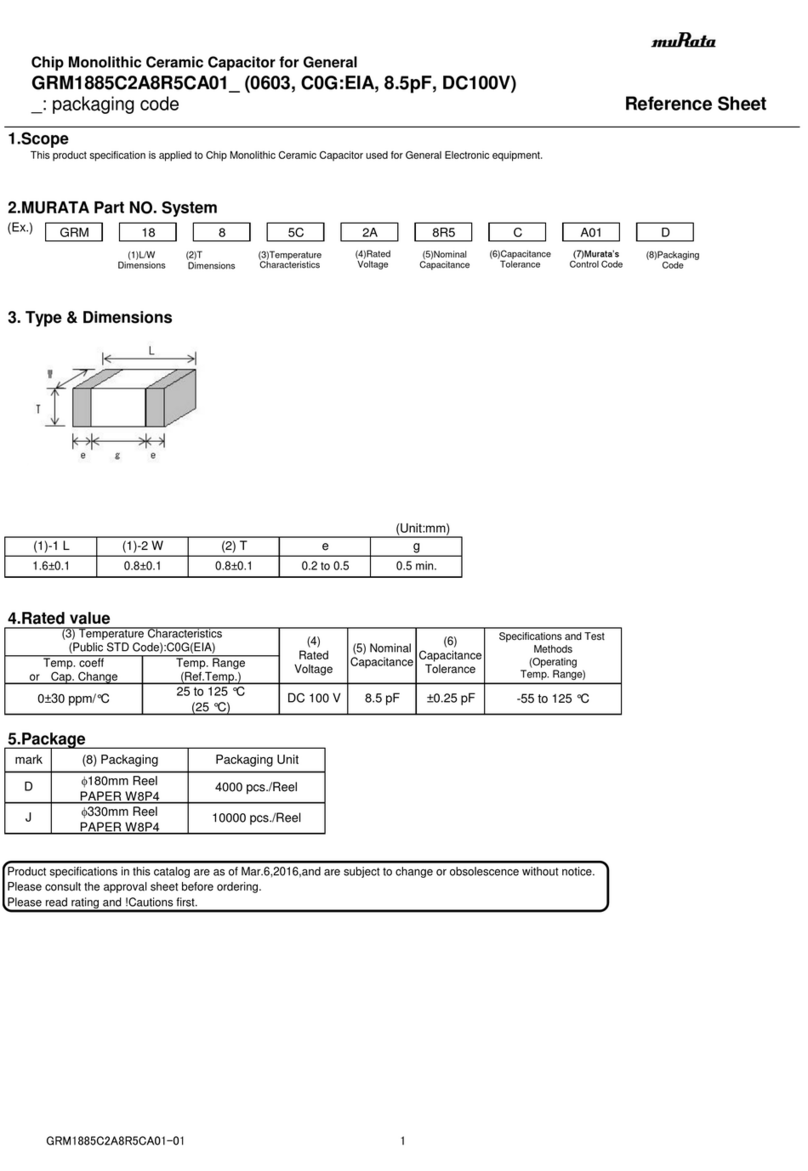

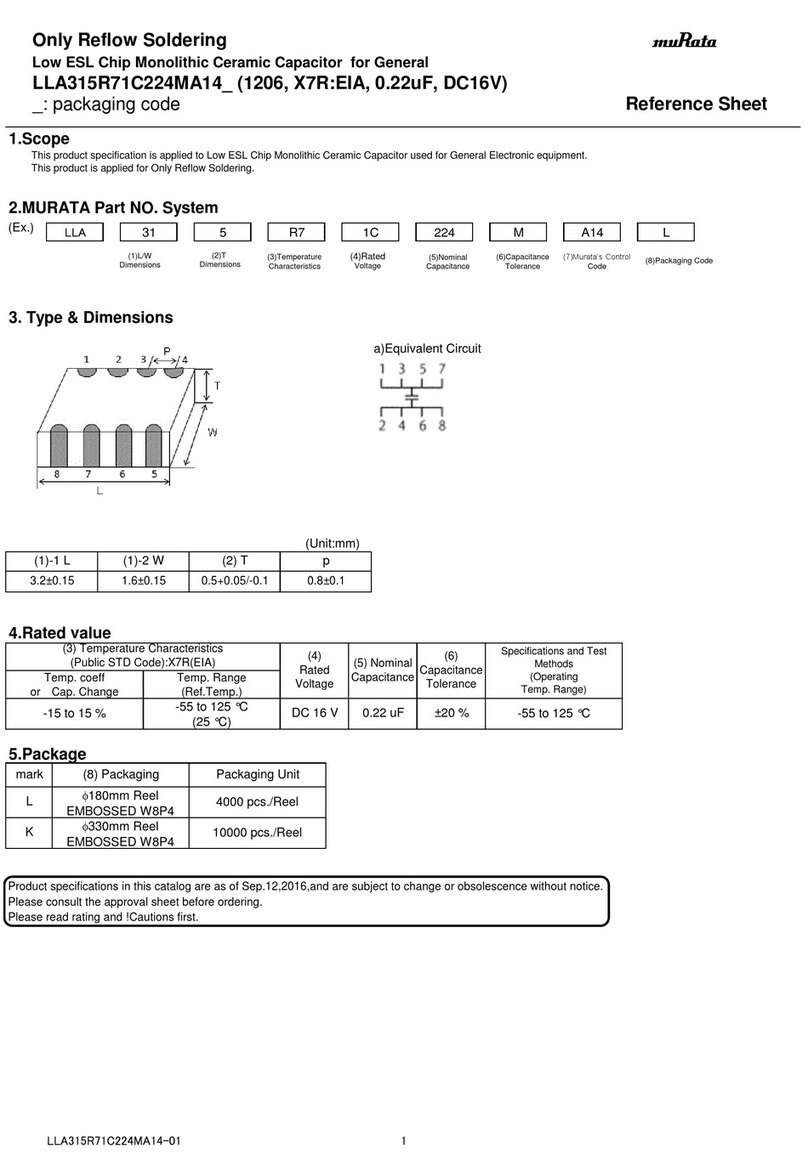

Murata

Murata LLA315R71C224MA14 Series Reference sheet

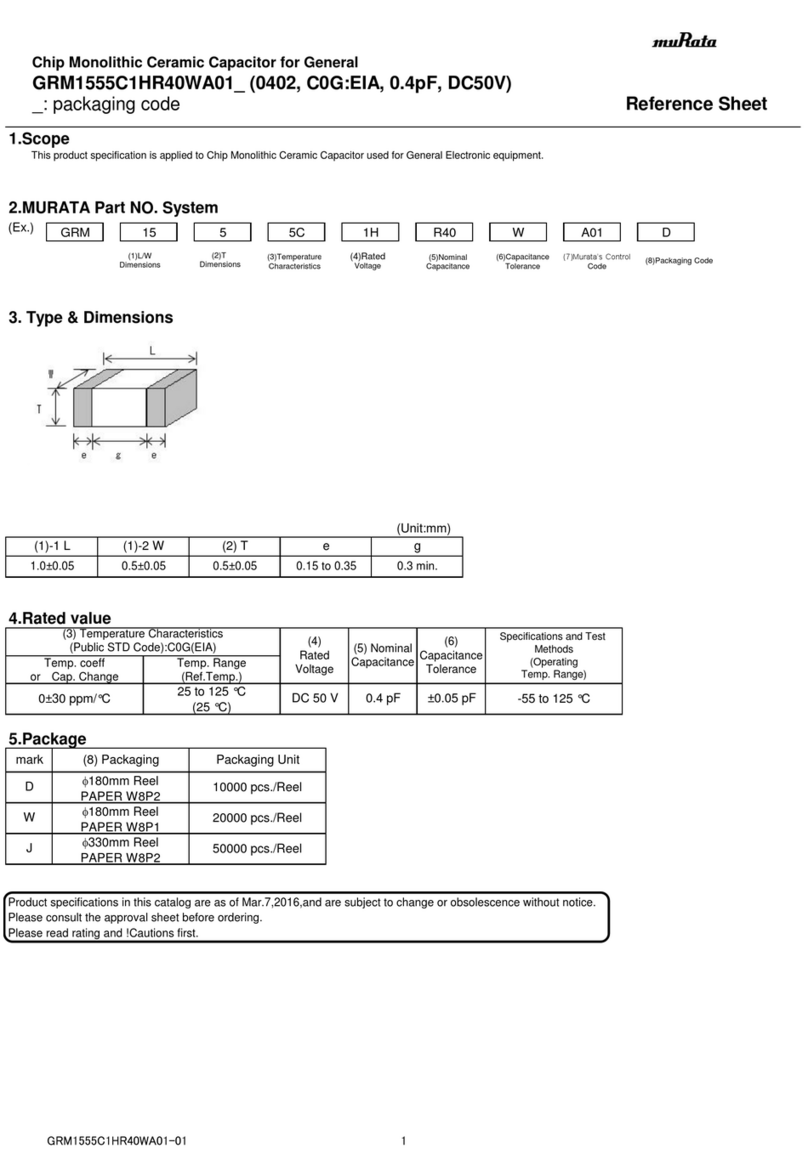

Murata

Murata GRM1555C1HR40WA01 Series Reference sheet

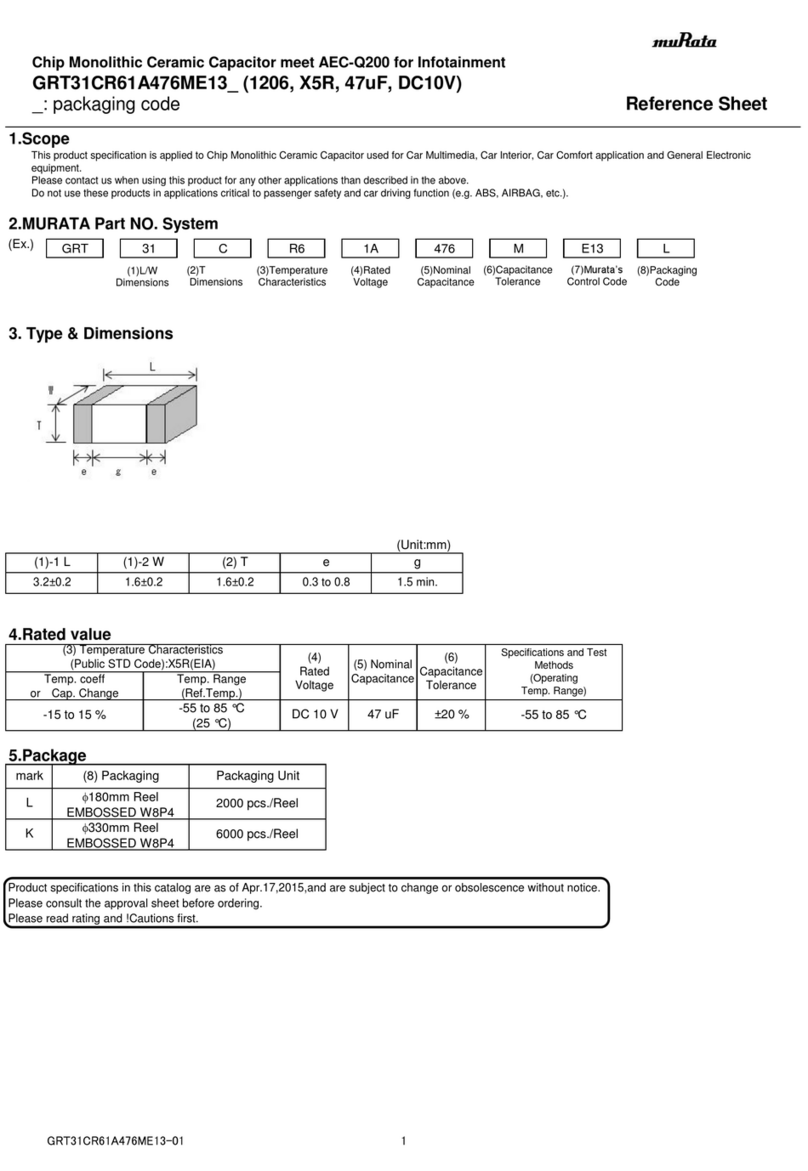

Murata

Murata GRT31CR61A476ME13 Series Reference sheet

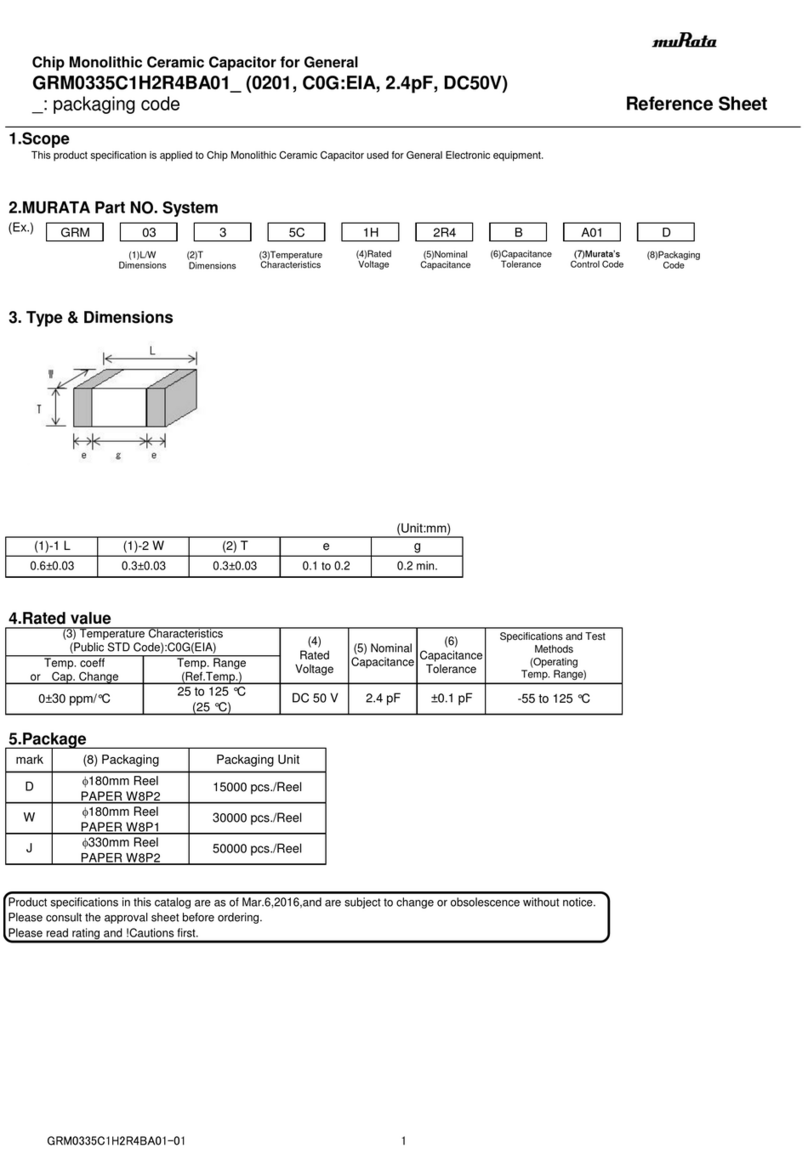

Murata

Murata GRM0335C1H2R4BA01 Series Reference sheet