Brehon Agrisystems G. Force User manual

Rev 06131 1

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

G.Force

Remote Control Systems

INTEGRATED RECEIVER/ENDGATE and

HOIST DRIVER CONTROL MANUAL

The G. Force Remote Control is designed to provide the ultimate in convenience and safety to

perform tasks remotely. It is a radio frequency (RF) controlled device that allows operation of a

gate, chute, etc. from a hand held transmitter operated remotely. The Transmitter, which operates at

418 MHz FM, transmits encoded information to the Receiver, which then decodes the information

and performs the desired function. When coupled with motor/driver, this system may be used to

operate a swinging gate, raise a chute, open a valve, etc. The Transmitter and Receiver are designed

to operate within 300' but actual range is dependent on operating environment.

Features :

Simplicity of design and quality of engineering.

User selectable security code.

Power On/Off switch on Receiver.

LED Indicator lights.

9v Transmitter Battery

Ease of installation/removal.

All controls can be by either Manual Keypad or Remote Control

Multiple Transmitters can operate a single Receiver.

Multiple Receivers can be operated by a single Transmitter.

Up to 4 different Channels can be operated by one Receiver

Manufactured By: Brehon Agrisystems Inc.

102 – 2750 Faithfull Ave.

Saskatoon, SK S7K 6M6

(306) 933 2655 phone/fax

Rev 06131 2

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

This device complies with part 15 of the FCC Rules / Industry Canada licence-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Specifications:

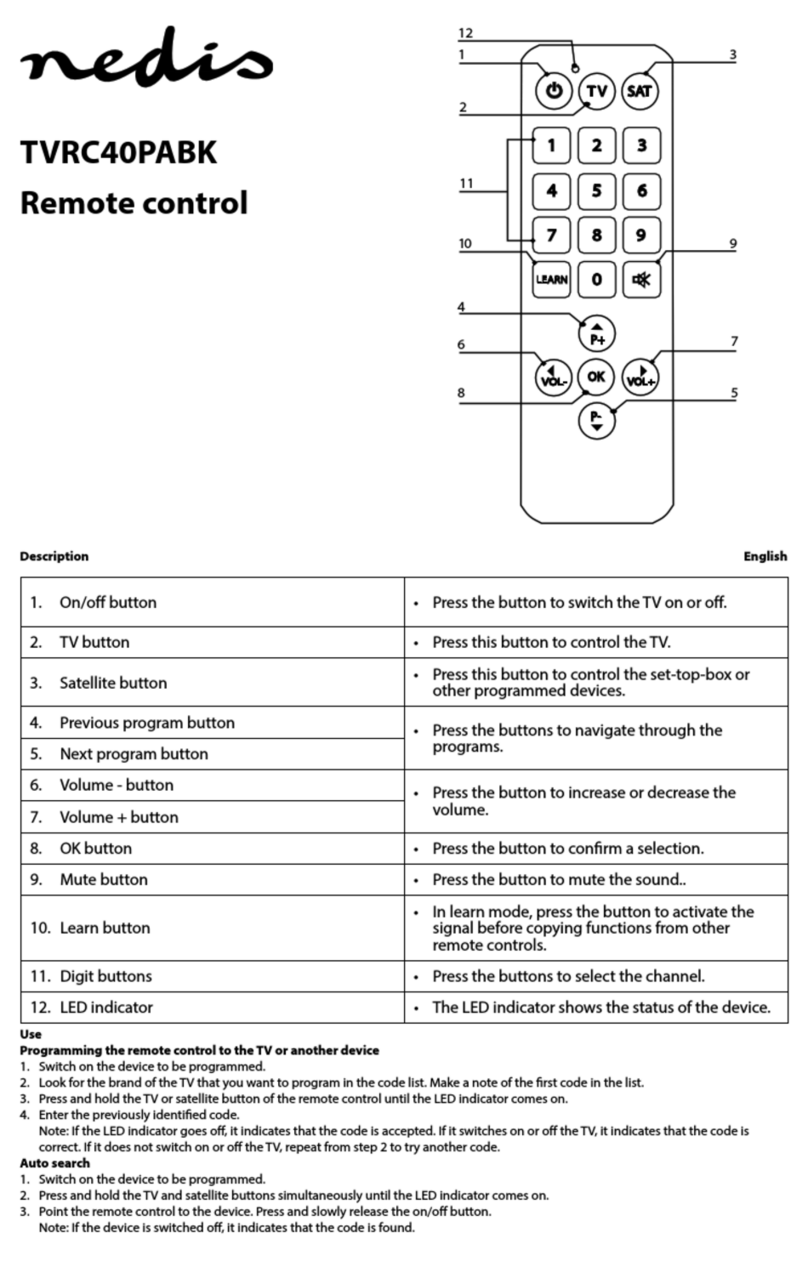

Transmitter:

Power: 9 volt dc battery

Frequency: 418 MHz

Modulation: FM

Indicators: Power/Transmit Red LED

Case Size: 2.6” x 4.1” x .9”

Weight: .25 lb.

Range: 300’+ (depending on environment)

Antenna: 1.3” Fixed Mini Tuned

Security Code: 3^8 selections

Safety: Off/Standby Slide Switch

Functions: 2 to 9 Button (depending on Model)

Receiver:

Power In: 12 vdc

Power Out: 12 vdc @ 10 amps max

Standby: 40mA

Security Code: 3^8 selections

Power Input: 4’ non-terminated 16ga wires

Hoist Inputs: Plug-and-Lock Connector

Indicators: Power On Red LED

Receive RF Data Yellow LED

Channel Active Green LED

Options: Latched/Momentary Data

Multi-Channel (1-4)

Main Power On/Off Switch

Manual Switch Control

Antenna: 7” Flexible Tuned

Case Size: 3.75” x 5” x 19”

Rev 06131 3

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

Weight: 5 lb.

Electric Cylinder Model ECL2S/12

Force: 540 lb.

Speed: .75 in/sec.

Stroke 11.8" Full Stroke

Closed Length: 18” Pin-to-pin

Electrical: 9.5A @ 12v Full Load

Duty Cycle: 5%

Hoist Driver (Optional)

Force: 40 in-lb Torque max

Speed: 6 rpm no load

Rotation: +/- 80 degrees

Electrical: 1A @ 12v Full Load

Duty Cycle: 10%

Size: 3” x 3.5” x 3.5”

Weight: 1 lb.

Connector: 4-pin Plug-n-lock

Cabling: 30’ of 4 Conductor 18ga. Wire with Fixed Connector both ends

Warning: Be sure truck hoist is securely blocked and valve lever

activated safely in both directions before beginning installation!

Think Safety:

Do Not install or operate where

Rev 06131 4

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

damage to property or persons may occur.

Rev 06131 5

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

INSTALLATION INSTRUCTIONS

Connecting Power to Receiver:

Using sufficiently heavy gage wire, (not included), connect +12vdc and Ground wires to the wire

from the Electric Cylinder marked POWER IN using the crimp connectors supplied. The

polarity must be correct as follows: +12v on the BLUE wire, and GROUND on the

BROWN wire. Power may be supplied from the fused side of the ACCessories on the ignition

switch so that the Receiver is only powered while the vehicle ignition key is on or alternatively,

connected using an inline fuse directly to battery power. When the Power ON/Off switch on the

bottom of the Receiver is turned on the Red LED indicator light should be ON indicating normal

operation.

Electric Cylinder Installation:

Before mounting the Electric Cylinder on the end gate, determine the correct location for installing

the mounting tabs by extending and retracting the cylinder to ensure required stroke. This can be

accomplished once power is supplied to the Receiver by pressing the ENDGATE manual switches

on the Receiver.

Ensure the grain chute operates freely. Position the mounting tabs such that when the grain chute is

fully open the cylinder is not quite fully retracted. Then check to ensure that the distance to fully

close does not exceed the electric cylinder stroke length and that the electric cylinder can be

mounted free of any obstacles.

Weld or drill/bolt the mount tabs in position on the vertical center-line of the grain chute and box

end panel at the desired positions.

Attach the cylinder main body to the top mount tab using the bolt and locknut supplied. Attach the

cylinder piston to the moveable grain chute with the snap pin supplied. Route the electrical wire

and connect using the insulated crimp terminals supplied. Secure all wires using the cable ties

provided.

NOTE: The existing lift handle on the endgate need not be removed, however, it must not be able

to lock in any position. This could cause the electric cylinder to stall resulting in reduced service

life or destruction.

Rev 06131 6

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

Vertical

Center

Line

Endgate

Driver

Truck

Endgate

Mounting Brackets

Installed on Vertical

Center Line

ENDGATE DRIVER INSTALLATION DRAWING

Rev 06131 7

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

Hoist Driver Installation:

Warning: Be sure truck hoist is securely blocked and valve lever

activated safely in both directions before beginning

installation!

Before beginning the installation carefully note which direction the lever arm on the valve moves

for “up” and “down” and note the Hoist Driver movement as indicated on the label.

With the truck box blocked and resting securely and the engine shut off, operate

the hoist control in both directions to ensure there is no pressure on the

hydraulic valve and the safety blocks are securely positioned.

Measure the distance the valve lever arm moves in either direction from its center rest position at

the mounting pin.

The hoist driver replaces the existing flexible cable control by bolting directly in its place on the

top of the hydralic valve/pump reservoir.

Disconnect the existing flexible cable control from the valve arm and unbolt the cable from the

reservoir bracket.

Select the appropriate hole to install the Hoist Driver Push Rod. The distance from the center of the

Hoist Driver Shaft Arm to the selected hole should be roughly the same as but not greater than

the distance the valve lever arm moves in either direction from its center rest position at the

mounting pin. The Hoist Driver Shaft Arm is designed to turn 80 degrees in either direction. If it is

stalled in either direction because the valve lever arm is not free to move, the Hoist Driver may be

damaged or destroyed.

Slide the Hoist Driver Push Rod through the valve lever arm cable clamp and bolt the Hoist Driver

to the reservoir mounting tab using the 5/16 x ¾ bolt, nut, flat washer, and lockwasher, provided.

Properly installed, the Hoist Driver Push Rod should be at right angles to the Hoist Driver Shaft

Arm. Ensure there is clearance for the movement of the valve lever arm, push rod, and shaft arm.

Tighten the existing valve lever arm cable clamp on to the Hoist Driver Push Rod.

Connect one end of the pre-wired 4 conductor hoist cable back to the Hoist Driver. Route the other

end to the Receiver and connect to the Receiver HOIST CONTROL connector. Secure the cable to

the truck chassis as required. Note: It does not matter which end is which.

Rev 06131 8

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

HOIST

DRIVER

Hydraulic Valve

SHAFT ARM

PUSH ROD

Valve Lever Arm

Pump & Reservoir

HOIST DRIVER INSTALLATION DRAWING

Rev 06131 9

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

General Operation:

RECEIVER:

The Receiver is equipped with a Power On/Off switch on the outside of the case. When the switch

is ON, the Red LED should be lit indicating normal operation.

The Receiver is equipped with an 8-position switch used to set the user security code. The security

code is provided to prevent unwanted operation of the Receiver by other devices. Only a

Transmitter with identical switch settings will be able to "talk" to this Receiver. When the switches

are set identically and the transmitter "talks" to the Receiver, the yellow “RECEIVE” light will

come on. This indicates that valid data with a matching security code has been received. Position

these switches to any desired On/Off pattern for your own security code. REMEMBER: The 8-

position switch on the Transmitter must be set IDENTICALLY. To access the security code switch,

remove the 6 screws securing the case from the rear and open the case.

NOTE: This is a TRI-STATE switch.

Each of the 8 switches has 3 positions which must

be identically matched to the corresponding Trans-

mitter/Receiver.

These code switches are fully compatible with 8-

position Two- State On/Off switches by using the

“+” setting as ON and the “O” setting as OFF.

USER SELECTABLE

SECURITY CODE SWITCH

8 - POSITION MUST BE SET

IDENTICAL

TO THE TRANSMITTER

Receiver Circuit Board O

1 2 3 4 5 6 7 8

-

+

DIP

Rev 06131 10

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

The Endgate and Hoist can be operated using the Transmitter, or alternatively, by pressing the

desired UP/DOWN arrows on the Receiver to activate the Manual Switches. Whenever the endgate

or hoist is operating, the Green LED indicating power to that device, will be lit.

Only one device can be operating at a time. The Hoist Driver will return to its Off (Neutral)

position before allowing any other output. The Manual Switches have priority over the Transmitter

signal when the Hoist Driver is in its OFF position.

The Receiver has two automatically resetting fuses. Fuse F1 (1 Amp) is intended to protect the RF

receiver and data circuitry, and Fuse F2 (10 Amp) is intended to protect the relays from overload.

These fuses will automatically reset when cooled

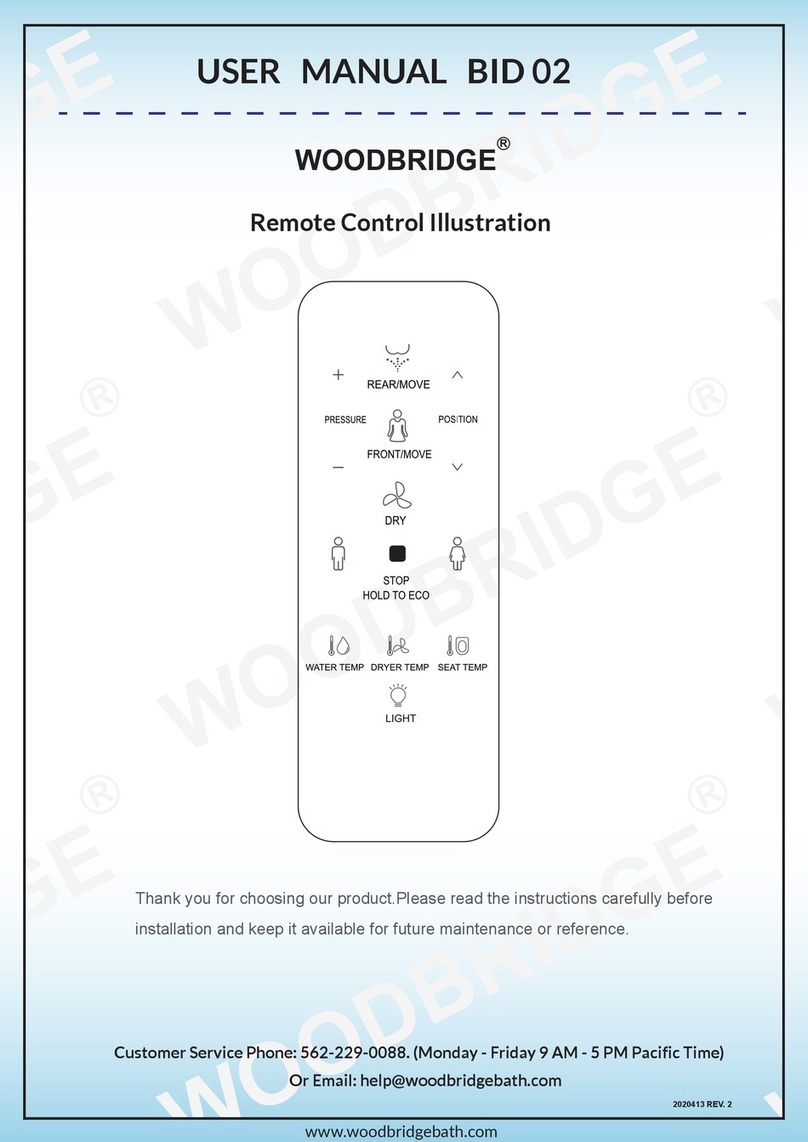

TRANSMITTER:

The Transmitter is powered by a 9v battery which, when installed, should light the red "power"

light when a switch is pressed. If the battery does not exceed 7 volts the Power light will not come

On, indicating battery replacement is required.

Set the 8-position switch to your own security code which matches the code on the Receiver to

which it is to "talk". Note that any number of Transmitters can "talk" to the same Receiver as long

as they have the security code which matches the receiver.

To access the Transmitter security code switch or battery, remove the 4 screws in the back of the

Transmitter case and open the case.

NOTE: The STOP button shown/included on the Transmitters is NOT USED as both the Hoist and

Endgate only operate while a button is held.

Think Safety:

Do Not install or operate where

damage to property or persons may occur.

Rev 06131 11

Brehon Agrisystems Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in

connection with the use or performance of the product or other damage with respect to any economic loss, loss of

property, loss of revenue or profit, or costs of removal, installation, or reinstallation.

ENDGATE DRIVER:

The Endgate Driver will only operate while its transmitter button/ manual switch control button is

depressed. Release the button immediately when the endgate is fully opened or closed. Do not

operate in a stalled condition. This could result in reduced service life or destruction of the Endgate

Driver.

The Receiver power switch should be turned Off when not in use to prevent undesired operation.

HOIST DRIVER:

The G. Force Hoist Driver shaft arm is designed to move each way from center and stay in that

position until its transmitter button/ manual switch control button is released or, as a safety default,

until input signal is otherwise lost. It will then return to the center Off (neutral) position. This

results in a slight delay from the time the button is released until the hoist actually stops. The Stop

button on the transmitter is not used - the actuator automatically returns to the center (neutral)

position.

The Receiver power switch should be turned Off when not in use to prevent undesired operation.

Think Safety:

Do Not install or operate where

damage to property or persons may occur.

Table of contents

Popular Remote Control manuals by other brands

Universal Remote

Universal Remote Aurora MX-950 brochure

Hilti

Hilti PRA 22 Original operating instructions

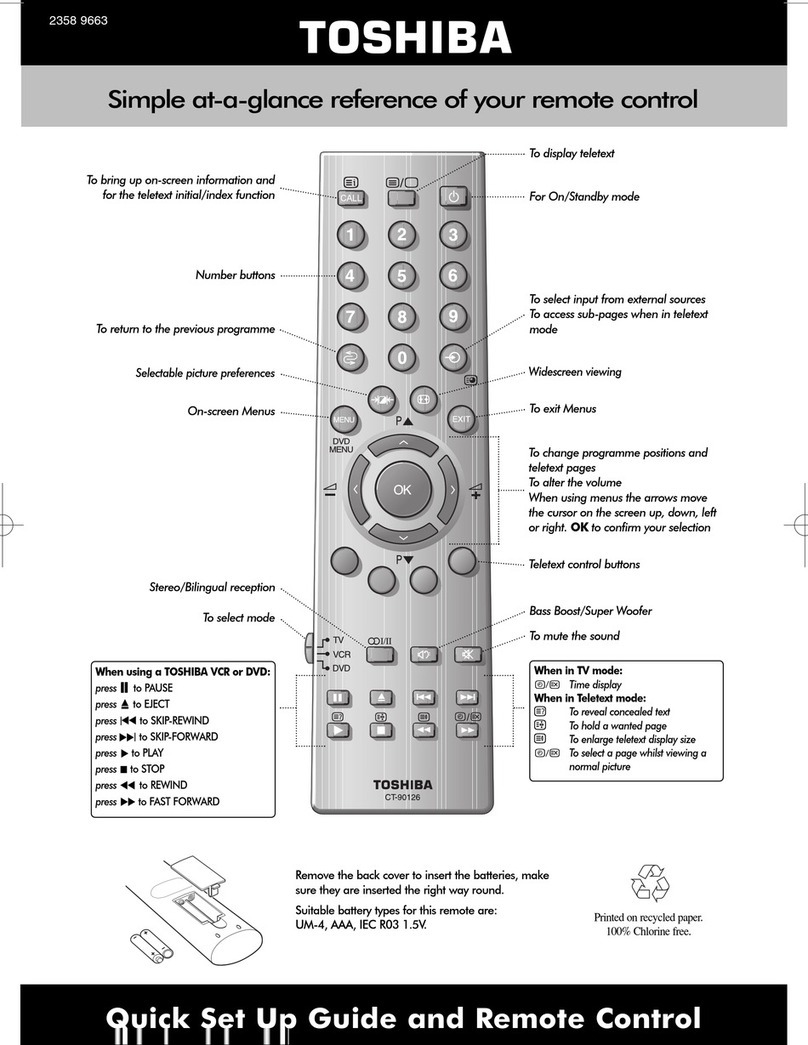

Toshiba

Toshiba 46WM48 Series Quick set up guide and remote control

Wacom

Wacom ExpressKey Remote user manual

LEDYi Lighting

LEDYi Lighting RT1 user manual

Hearth and Home Technologies

Hearth and Home Technologies RCT-MLT-II Installation and operating instructions