Bremer VIVA User manual

Information for bremer Customer Service /

Table of contents / index

Dimensions, table cut-outs

Operating instructions

Adjustments prior to operation

Removing the housing

Structural components

Menu control

Control system / circuit diagrams, function diagram,

terminal diagrams

Faults and remedies / special tools

Miscellaneous

Service Manual

bremer VIVA

These service instructions are intended for authorised bremer Cu-

stomer Service staff only!

The adjustments, repairs and maintenance work described in these

service instructions may only be carried out by qualified bremer ser-

vice engineers using original bremer spare parts!

Safety information in service instructions

Caution: Always de−energise the unit before opening it!

If, for some reason, the unit has to be put into operation when open,

please observe the following instructions:

WARNING! Risk of accident from electric shock!

Protect conductive parts against accidental contact, e.g. by covering

them with an insulating mat.

WARNING! Risk of crushing!

Beware moving parts, e.g. during functional tests

CAUTION! Destruction of components!

Do not place any conductive objects on printed circuit boards

No static discharge may take place via lifters!

1

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

1. Table of Contents Page

Index (after Table of Contents) A

2. Dimensions, table cut−outs 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Outer dimensions 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Table cut−outs 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Operating instructions 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Adjustments prior to operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Setting the coffee quality (till Software-Version 2.05) 4-1. . . . . . . . . . . . .

4.2 Standard settings (since Software-Version 3.02) 4-2. . . . . . . . . . . . . . . . .

VIVA TRAIN COOL With 2 Grinders −Factory Setting (Type 984329) 4-10. . . .

5. Removing the housing 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Opening ”upper front panel” / removing ”lower front panel” 5-1. . . . . . . .

5.2 Removing the left / right−hand side section 5-3. . . . . . . . . . . . . . . . . . . . .

5.3 Removing the rear panel 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Removing the bean container 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Removing the drip tray and drip tray base 5-4. . . . . . . . . . . . . . . . . . . . . .

5.6 Removing the container ejection cover 5-5. . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Inserting the ejection pit for container ejection 5-5. . . . . . . . . . . . . . . . . . .

6. Structural components 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Coffee grinder 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Adjusting the grinding fineness 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Weighing the ground coffee 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Removing the coffee grinder 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4 Replacing the grinding wheels 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.5 Technical data of coffee grinder motor 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.6 Electrical connection of coffee grinder motor 6-4. . . . . . . . . . . . . . . . . . . . . .

2

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

6.2 Brewing unit 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Operation of brewing unit 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Maintenance of brewing unit 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Checking/adjusting the brewing unit 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 Removing the brewing unit from the machine 6-11. . . . . . . . . . . . . . . . . . . . .

6.2.5 Replacing worn parts of the ”upper plunger” 6-12. . . . . . . . . . . . . . . . . . . . . .

6.2.6 Replacing worn parts of the ”lower plunger” 6-13. . . . . . . . . . . . . . . . . . . . . . .

6.2.7 Replacing the wiper profile 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.8 Replacing the supporting element 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.9 Test run of brewing unit 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.10Technical data of motor 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.11 Quick coupling/teflon hose 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Reference point switch and encoder (photelectric barrier) 6-17. . . . . . . . .

6.3.1 Operation of reference point switch 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Operation of encoder 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Technical data of photoelectric barrier 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Grounds container and microswitch 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Operation 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Technical data of microswitch 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Pressure regulator 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Operation 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Maintenance: cleaning the pressure regulator cartridge 6-19. . . . . . . . . . . . .

6.5.3 Technical data of pressure regulator 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Flow sensor 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Operation 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Removing and replacing the flow sensor 6-21. . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 Technical data of flow sensor 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Motor-driven pump 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Checking/adjusting the motor-driven pump 6-22. . . . . . . . . . . . . . . . . . . . . . .

6.7.2 Maintenance of pressure regulating device on pump head 6-22. . . . . . . . . . .

6.7.3 Removing the pump head / removing the motor-driven pump 6-23. . . . . . . .

6.7.4 Technical data of motor-driven pump 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.5 Electrical connection of motor-driven pump 6-24. . . . . . . . . . . . . . . . . . . . . . .

6.8 Brewing water boiler 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.1 Operation of brewing water boiler (installed on left-hand side of machine) . . . .

6-25

6.8.2 Temperature settings for brewing water boiler 6-27. . . . . . . . . . . . . . . . . . . . .

6.8.3 Maintenance intervals for brewing water boiler 6-27. . . . . . . . . . . . . . . . . . . .

6.8.4 Inspection of brewing water boiler 6-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.5 Technical data of brewing water boiler 6-27. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Hot water/steam boiler 6-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.1 Operation of hot water/steam boiler (installed on right-hand side of machine)

6-28

6.9.2 Maintenance interval for hot water/steam boiler 6-31. . . . . . . . . . . . . . . . . . . .

6.9.3 Checking the hot water/steam boiler 6-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.4 Technical data of hot water/steam boiler 6-31. . . . . . . . . . . . . . . . . . . . . . . . . .

3

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

6.10 Removing the brewing water or hot water/steam boiler 6-32. . . . . . . . . . .

6.11 Safety thermostat (bimetallic thermostat) 6-33. . . . . . . . . . . . . . . . . . . . . . .

6.11.1 Technical data of safety thermostat 6-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12 Safety valves 6-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.1Checking/maintenance of safety valves 6-34. . . . . . . . . . . . . . . . . . . . . . . . . .

6.13 Solenoid valves 6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.13.1Technical data of solenoid valves 6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14 NTC temperature sensor 6-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14.1Operation/graph of NTC temperature sensor 6-36. . . . . . . . . . . . . . . . . . . . . .

6.14.2Checking/replacing the NTC temperature sensor 6-37. . . . . . . . . . . . . . . . . .

6.15 Air valve (removed at 30.8.99) 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.15.1Operation of air valve 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.15.2Maintenance of air valve 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16 Pressure switch 6-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16.1Operation of pressure switch 6-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16.2Checking/maintenance of pressure switch 6-40. . . . . . . . . . . . . . . . . . . . . . . .

6.16.3Technical data of pressure switch 6-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17 Check valve 6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.1Maintenance of check valve 6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18 Electrode for hot water/steam boiler water level 6-42. . . . . . . . . . . . . . . . .

6.18.1Operation 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18.2Checking 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18.3Maintenance 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.19 Coffee dispenser with frother head 6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.19.1Operation 6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.19.2Adjusting the milk froth dispenser 6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.19.3Maintenance / cleaning / replacement of O-rings 6-45. . . . . . . . . . . . . . . . . . .

6.19.4Connections 6-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.20 Emptying of Boilers (VIVA TRAIN) 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Menu control 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Settings/displays 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Service menu (1st gen.) 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Exit service menu 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Control system 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Arrangement of fuses and relays 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

8.2 Uninstalling/changing the fuses 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Removing the relays 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Replacing the rectifier pcb/transformer 8-2. . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Circuit diagrams/function diagrams 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Faults and remedies 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Machine error code display 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Faults and remedies 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Special tools/lubricants 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. Miscellaneous 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Water boiler (VIVA au lait, VIVA Barista, Europa) 10-2. . . . . . . . . . . . . . . .

10.1.1Technical data: water boiler (VIVA au lait, Barista) 10-3. . . . . . . . . . . . . . . . .

10.2 HW Steam boiler (VIVA Barista, Europa) 10-3. . . . . . . . . . . . . . . . . . . . . . .

10.2.1Technical data HW Steam boiler (VIVA Barista Europa) 10-4. . . . . . . . . . . . .

10.3 HW Steam boiler (VIVA McD) 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1Technical data HW Steam boiler (VIVA McD) 10-6. . . . . . . . . . . . . . . . . . . . . .

10.4 Water boiler (VIVA 220V 3.0 kW UL, America) 10-7. . . . . . . . . . . . . . . . . .

10.4.1Technical data: water boiler (VIVA 220V 3.0 kW UL, America) 10-8. . . . . . .

10.4.2Safety valve for water boiler (VIVA 220V 3.0 kW UL, America) 10-8. . . . . . .

10.5 Hot water steam boiler (VIVA Barista UL, America) 10-9. . . . . . . . . . . . . .

10.5.1Technical data HW Steam boiler (VIVA Barista UL, America) 10-10. . . . . . . .

10.5.2Safety valve HW Steam boiler (VIVA Barista UL, America) 10-10. . . . . . . . . .

10.5.3Pressure switch HW Steam boiler (VIVA Barista UL, America) 10-11. . . . . . .

10.6 Completion of Service-Menu −control board II (2cd gen.) 10-12. . . . . . . . .

10.7 Set the language for the menue 10-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8 Prevented Service for Brita water softener 10-14. . . . . . . . . . . . . . . . . . . . . .

10.9 Software to the new PC board, PlugIn (Version II) 10-16. . . . . . . . . . . . . . .

10.10Short instructions for cleaning the milkpipe and brewing unit 10-19. . . . . .

10.11Functional Description VIVA au lait, Type 810 . . . 10-23. . . . . . . . . . . . . . . .

10.12Functional description VIVA au lait, type 807, 813 . . . 10-30. . . . . . . . . . . .

10.13Description of function VIVA Barista, type 807 . . . 10-37. . . . . . . . . . . . . . .

A

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

Index

A

Adjustment

Brewing time for each article, 7-2

Grinding fineness, 6-1

Hot water metered or not metered, 7-3

Milk froth dispenser, 6-44

Motro-driven pump, 6-22

Number of ground tablets for ground con-

tainer, 7-2

Temperature of brewing water boiler, 7-2

Voltage, 7-3

Air Valve

Maintenance,6-38

Operation, 6-38

Steam pipe Barista, 10-40

B

Brewing unit, 6-5

Checking / adjusting the brewing unit, 6-9

Maintenance, 6-8

Operation of brewing unit, 6-5

Removing the brewing unit from the ma-

chine, 6-11

Replacing the supporting element of bre-

wing unit, 6-14

Replacing the wiper profile of brewing

unit, 6-14

Replacing worn parts of brewing unit

lower plunger, 6-13

upper plunger, 6-12

Technical data of motor, 6-15

Test run of brewing unit, 6-15

Brewing water boiler

Filling, 6-25

Inspection of brewing water boiler, 6-27

Maintenance intervals, 6-27

Operation, 6-25

Removal, 6-32

Technical data, 6-27

C

Check valve, 6-41

Maintenance, 6-41

Checking

Brewing unit, 6-9

Brewing water boiler, 6-27

Electrode for hot water/steam boiler, 6-42

Hot water/steam boiler, 6-31

Motro-driven pump, 6-22

NTC temperature sensor, 6-37

Pressure switch, 6-40

Safety valves, 6-34

Circuit diagrams, 8-3

Cleaning, Coffee dispenser/frother

head, 6-45

short instruction, 10-19

Closing the front panel, 5-2

Coffee dispenser

Maintenance / cleaning / replacement of

O-rings, 6-45

Replacement of O-rings, 6-44

Coffee dispenser with frother head,

6-43

Connections, 6-45

Operation, 6-43

Coffee grinder, 6-1

Adjusting the grinding fineness, 6-1

Assembly, 6-3

Electrical connection, 6-4

Removing the coffee grinder, 6-2

Replacing the grinding wheels, 6-3

Technical data, 6-4

Weighing the ground coffee, 6-2

Connections, coffee dispenser/frother

head, 6-45

Container ejection, Inserting the ejec-

tion pit, 5-5

Control system, 8-1

Arrangement of fuses and relays, 8-1

D

Dimensions, 2-1

B

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

Display of error codes, 9-1

Displays

Number of completed brewing, 7-3

Software version, 7-3

E

Electrical connection

Motor of coffee grinder, 6-4

Motor-driven pump, 6-24

Electrode for hot water/steam boiler

water level

Check, 6-42

Maintenance, 6-42

Operation, 6-42

Encoder (photelectric barrier), 6-17

Error codes, 9-1

F

Faults and remedies, 9-1

Flow sensor, 6-21

Frother head

Adjustment dispenser of milk froth, 6-44

Connections, 6-45

Function diagram, 8-3

Fuses, 8-1

changing, 8-1

uninstalling, 8-1

G

Grounds container and microswitch,

6-18

Operation, 6-18

Grounds tablets, adjust number for

grounds container, 7-2

H

Hot water metered or not metred, 7-3

Hot water/steam boiler

Check, 6-31

Maintenance interval, 6-31

Operation, 6-28

Removal, 6-32

Technical data, 6-31

VIVA Barista UL, HW steam boiler,

10-9

Technical data

HW Steam boiler VIVA au lait, Barista,

10-3

HW Steam boiler VIVA McD, 10-6

Water boiler 220V 3kW UL, 10-8

L

Lubricants, 9-3

M

Machine error code display, 9-1

Maintenance

Air valve, 6-38

Brewing unit, 6-8

Check valve, 6-41

Cleaning the pressure regulator cartridge,

6-19

Coffee dispenser, froth dispenser, 6-45

Electrode for hot water/steam boiler water

level, 6-42

Motor-driven pump, 6-22

Pressure switch, 6-40

Safety valves, 6-34

Maintenance / cleaning / replacement

of O-rings, 6-45

Maintenance intervals

Brewing water boiler, 6-27

Checking the hot water/steam boiler, 6-31

Menu control, 7-1

Microswitch

Dispenser block, 6-45

Grounds container, 6-18

Photo documentation, 10-29

Photo Documentation, 10-30

Motor-driven pump

Checking / adjusting, 6-22

Electrical connection, 6-24

Maintenance, 6-22

Removing, 6-23

Technical data, 6-24

C

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

N

NTC temperature sensor, 6-36

Checking/replacing,6-37

Operation/graph, 6-36

O

Opening the ”upper front panel”, 5-1

Operating instructions, 3-1

Operation

Air valve, 6-38

Brewing unit, 6-5

Coffee dispenser with frother head, 6-43

Electrode for hot water/steam boiler water

level, 6-42

Encoder (photeelectric barrier), 6-17

Flow sensor, 6-21

Hot water/steam boiler, 6-28

NTC temperature sensor, 6-36

Pressure regulator, 6-19

Pressure switch, 6-39

Reference point switch, 6-17

P

Photoelectric barrier, Technical data,

6-17

Pressure regulator

Ceaning cartridge, 6-20

Maintenance, 6-19

Operation, 6-19

Replacing cartridge, 6-20

Technical data, 6-20

Pressure switch

Check and maintenance, 6-40

Operation, 6-39

Technical data, 6-40

HW Steam boiler VIVA UL, Pressure

switch 1.3 bar, 10-11

Prior to operation, 4-1

Q

Quick coupling/teflon hose, 6-16

Quit, service menu, 7-4

R

Rectifier pcb, replace, 8-2

Reference point switch, Operation,

6-17

Relay, 8-1

Removal, 8-2

Removing

Bean container, 5-4

Brewing unit from the machine, 6-11

Brewing water or hot water/steam boiler,

6-32

Coffee grinder, 6-2

Container ejection cover, 5-5

Drip tray and drip tray base, 5-4

Flow sensor, 6-21

Housing, 5-1

Lower front panel, 5-1

Motor-driven pump, 6-23

Pump head, 6-23

Rear panel, 5-3

Relay, 8-2

Side section, 5-3

Replacing

Grinding wheels, 6-3

NTC temperature sensor, 6-37

Supporting element, 6-14

Teflon hose, 6-16

Wiper profile, 6-14

Worn parts of the lower plunger, 6-13

Worn parts of the upper plunger, 6-12

S

Safety thermostat

Operation, 6-33

Replacing, 6-33

Technical data, 6-33

Water boiler 220V 3kW UL, Safety

valve, 10-8

Safety valves, 6-34

Check, maintenance, 6-34

Service menu, 7-2

Side section removing, 5-3

Solenoid valves, 6-35

Technical data, 6-35

D

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

Special tools/lubricants, 9-3

Structural components, 6-1

T

Table cut−outs, 2-3

HW Steam boiler Barista UL

Safety valve 2 bar, 10-10

Technical data, 10-10

HW Steam boiler VIVA Barista Europa,

Technical data, 10-4

Technical data

Brewing water boiler, 6-27

Flow sensor, 6-21

Hot water/steam boiler, 6-31

Microswitch, grounds container, 6-18

Motor of brewing unit, 6-15

Motor of coffee grinder, 6-4

Motor-driven pump, 6-24

Photoelectric barrier, 6-17

Pressure regulator, 6-20

Pressure switch, 6-40

Safety thermostat, 6-33

Solenoid valves, 6-35

Teflon hose

Inserting, 6-16

Removal, 6-16

Replacing, 6-16

Test run of brewing unit, 6-15

Transformer, replace, 8-2

V

HW Steam boiler 3.3 kW, VIVA Bari-

sta, Europa, 10-3

Description of function, 10-38

Functional Description, 10-23, 10-31

HW Steam boiler, VIVA McD, 10-5

Voltage, Adjustment, 7-3

W

VIVA 220V 3kW UL, Water boiler, 10-7

VIVA au lait / VIVA Barista, Europa,

Water boiler 3.3 kW, 10-2

Weighing the ground coffee, 6-2

2-1

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

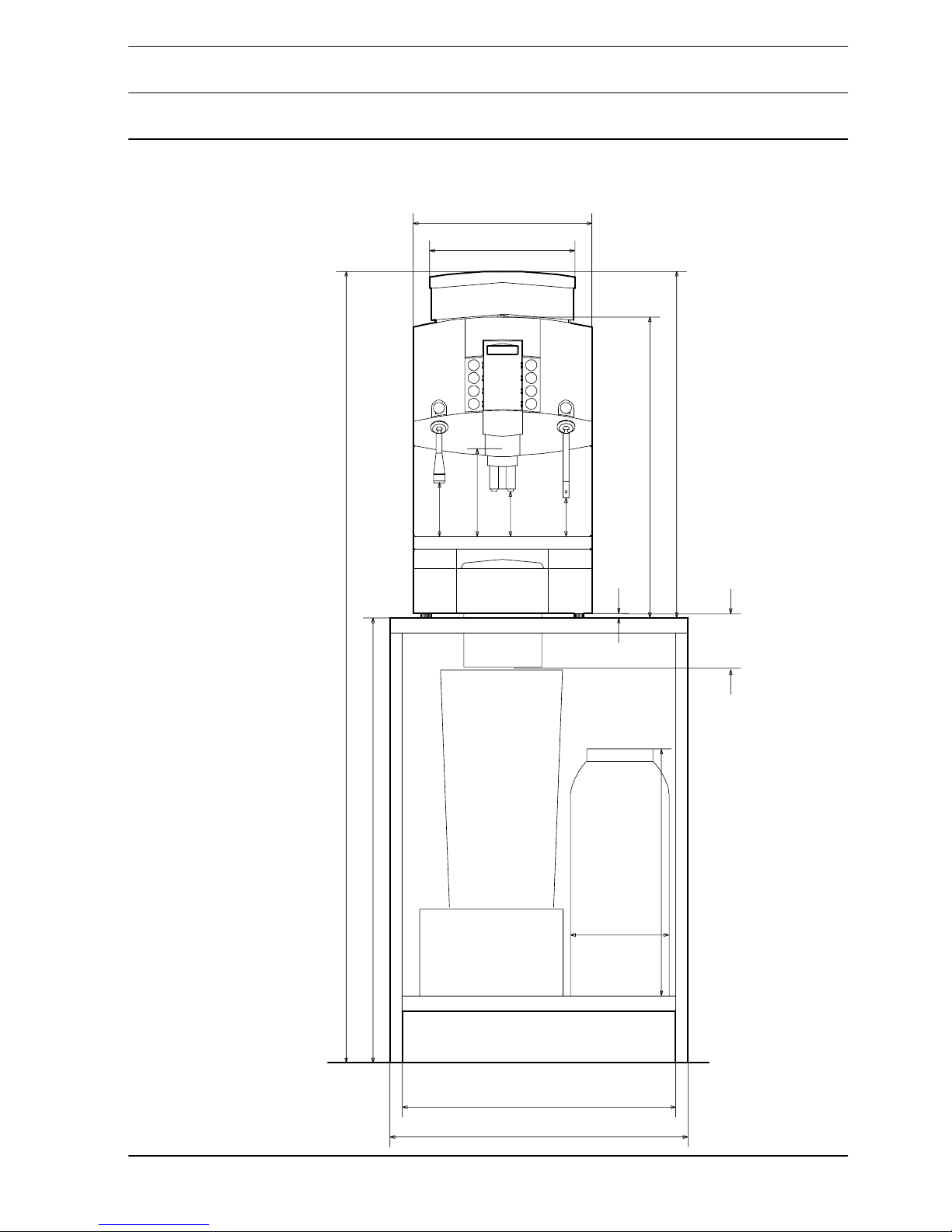

2. Dimensions, table cut−outs

2.1 Outer dimensions

Front view

Water

softener

Coffee

container

360

295

115

105

75

max.177

10

607

700

900

1600

500

220

560

600

ca.

130

ground

2-2

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

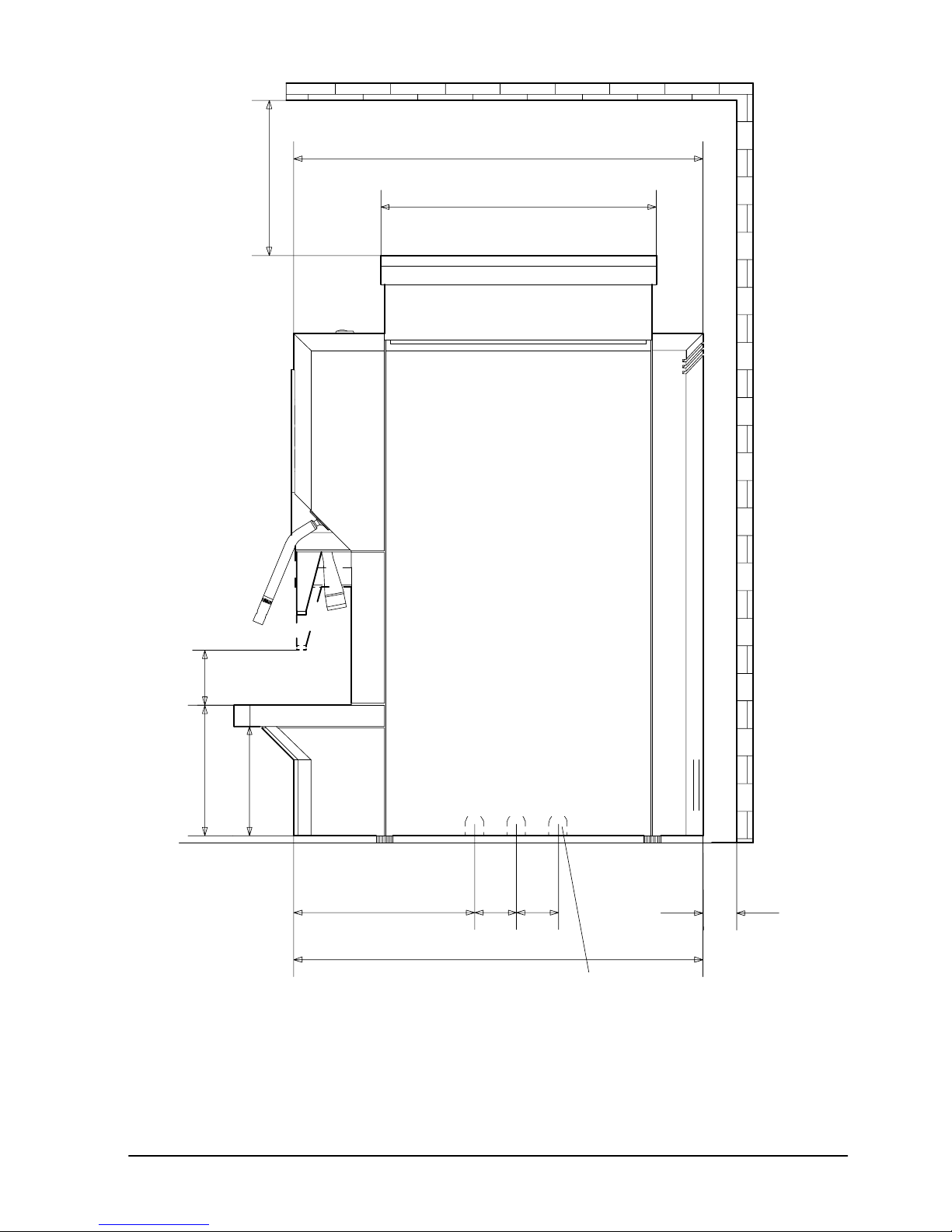

Side view

Cut−outs possible on both sides for

routing connections.

5050

min.70

40

min.200

221

130

155

490

330

497

2-3

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

2.2 Table cut−outs

Table cut−out

for water

inlet/outlet

pipes and

connecting

cable d=80

80

360

92

185

560

container ejection /

118 124

242

93 174

235

area

d=80 mm

3-1

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

3. Operating instructions

Operating instructions bremer VIVA in German, identity no.: 652067

Operating instructions “neutral” in English, identity no.: 668613

Operating instructions bremer VIVA in English, identity no.: 659800

Operating instructions bremer VIVA in Japanese, identity no.: 663204

Operating instructions bremer VIVA in French, identity no.: 684716

Operating instructions bremer VIVA in Netherland, identity no.: 690899

4-1

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

4. Adjustments prior to operation

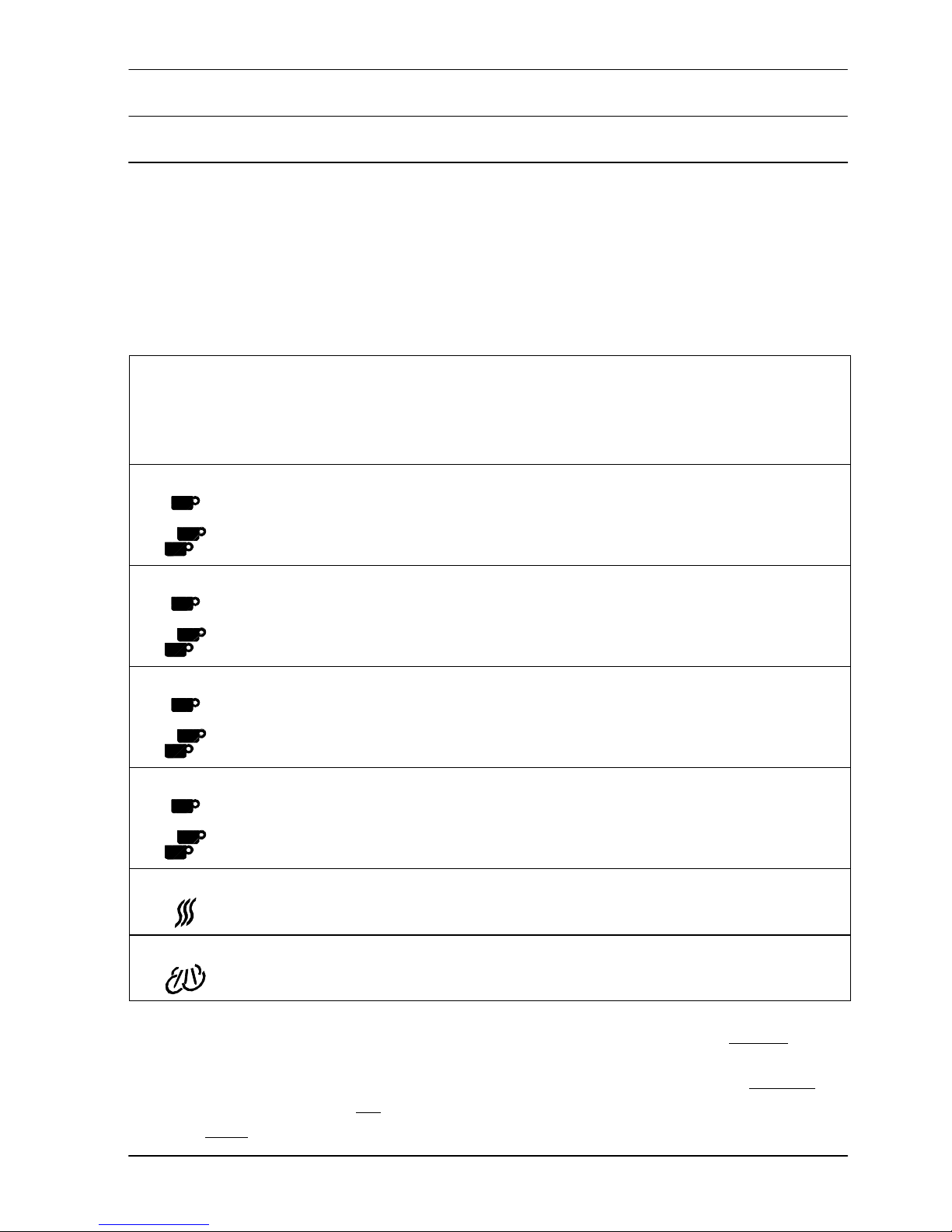

4.1 Setting the coffee quality (till Software-Version 2.05)

See operating instructions for how to assemble and connect the machine.

Set the machine to the coffee quality required by the customer: coffee type, cof-

fee bean quanity, water quantity, etc.

Standard factory setting for VIVA Standard (up to Vers. 2.05)

Article Grinder Ground

coffee

quantity

app.

1/100 s

Brewing

water

app 0,5

ml / imp.

Brewing

pres-

sure

Milk

froth

ON = Y7

open

Milk

dosage

Brewing

time

Grinder

locking

position

Coffee

centre 220 265 OFF ON 0 0 9

centre 380 530 OFF ON 0 0 9

Cafe Crème

right 220 240 ON ON 0 140 6

right 380 480 ON ON 0 200 6

Espresso

left 220 120 ON ON 0 100 6

left 380 240 ON ON 0 160 6

Cappuccino

left 220 200 ON ON 200 140 6

left 380 400 ON ON 300 200 6

Hot water

- - 100 - - - - -

Steam

- - - - - - - -

Brewing temperature: 93°C Hot water dispensing: metered / not−

metered

Capacity of grounds container: 100 tablets Dampfausgabe: dosiert / undosiert

Steam boiler available: YES / NO Pump pressure: 8 bar

Voltage: 230 V / 400 V

4-2

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

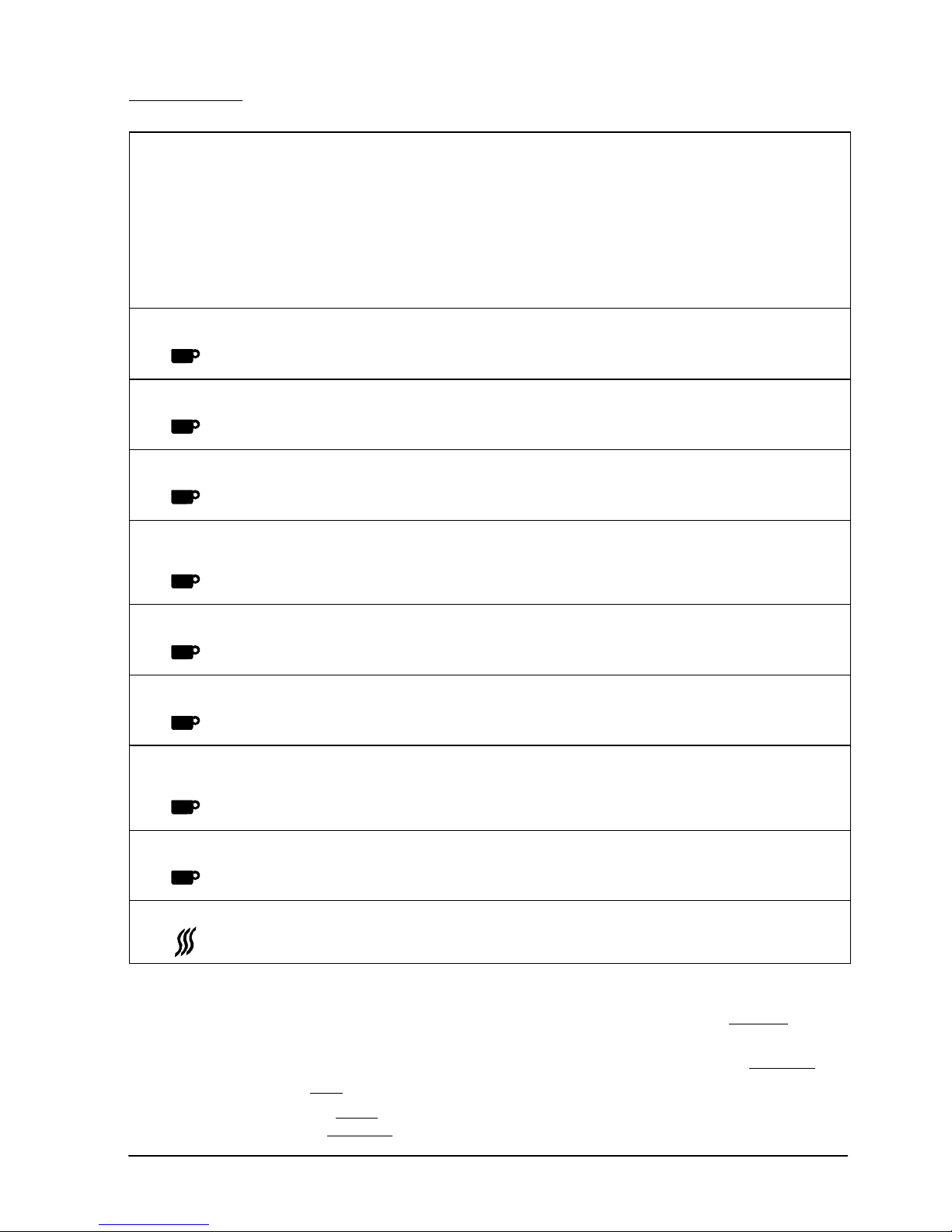

4.2 Standard settings (since Software-Version 3.02)

VIVA Standard factory setting with 3 coffee grinders (since Vers. 3.02)

Article Grin-

der

left

centre

right

Grinder

locking

position

0-14

Groun

d cof-

fee

quan-

tity

0-999

app.

1/100 s

Bre-

wing

water

0-999

app. 0,5

ml / imp.

Brewing

pres-

sure

OFF, ON

Bre-

wing

time

(only if

brewing

pres-

sure is

ON)

Milk

froth

0-999

Milk

do-

sage

0-999

Dosing

se-

quence

B=brewing

M=milk

MS= milk

foam

1, 2, 3,

0=Aus

Coffee B=1

M=0

MS=0

centre 12 170 265 OFF 0 0 0

centre 12 280 530 OFF 0 0 0

Cafe Crème B=1

M=0

MS=0

right 10 240 240 ON 140 0 0

right 10 380 480 ON 200 0 0

Espresso B=1

M=0

MS=0

left 10 240 120 ON 100 0 0

left 10 380 240 ON 160 0 0

Cappuccino B=1

M=0

MS=1

left 10 240 200 ON 140 200 0

White coffee B=1

M=1

MS=0

left 10 220 150 ON 100 0 90

Hot water

- - - 100 - - - - -

Brewing temperature: 93°C Hot water dispensing: metered / not−

metered

Capacity of grounds container: 100 tablets Dampfausgabe: dosiert / undosiert

Steam boiler available: YES / NO Pump pressure: 8 bar

old: Voltage: 230 V / 400 V

new: E1-E2 locked / unlocked

Pressure-reducing valve in the

equipment: 2.6 bar

4-3

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

VIVA Standard - Notes for customer’s settings

Article Grin-

der

left

centre

right

Grinder

locking

position

0-14

Groun

d cof-

fee

quan-

tity

0-999

app.

1/100 s

Bre-

wing

water

0-999

app 0,5

ml / imp.

Brewing

pres-

sure

OFF, ON

Bre-

wing

time

(only if

brewing

pres-

sure is

ON)

Milk

froth

0-999

Milk

do-

sage

0-999

Dosing

se-

quence

B=brewing

M=milk

MS= milk

foam

1, 2, 3,

0=Aus

Coffee

Cafe Crème

Espresso

Cappuccino

White coffee

Hot water

Brewing temperature: Pump pressure:

Grounds container capacity:

Steam boiler available:

Voltage / E1-E2 locked:

Hot water dispensing:

Customer: Coffee roaster:

4-4

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

VIVA au lait −without adjustable milk dosage −factory setting

Article Grin-

der

left

centre

right

Grin-

der

lok-

king

posi-

tion

0-14

Groun

d cof-

fee

quan-

tity

0-999

app.

1/100 s

Bre-

wing

water

0-999

app. 0,5

ml / imp.

Bre-

wing

pres-

sure

OFF, ON

Bre-

wing

time

(only if

brewing

pressure

is ON)

Milk

froth

0-999

Milk

do-

sage

0-999

Dosing

se-

quence

B=bre-

wing

M=milk

MS= milk

foam

1, 2, 3,

0=Aus

Coffee

centre 12 170 265 OFF 0 0 0

B=1

M=0

MS=0

Cafe Crème

right 10 240 240 ON 140 0 0

B=1

M=0

MS=0

Espresso

left 10 240 120 ON 100 0 0

B=1

M=0

MS=0

Latte

Macchiato

left 10 240 200 ON 140 200 0

B=3

M=1

MS=2

Cappuccino

left 10 240 200 ON 140 200 0

B=1

M=0

MS=1

White coffee

left 10 220 150 ON 100 0 90

B=1

M=1

MS=0

Espresso

Macchiato

left 10 240 120 ON 100 0 0

B=1

M=0

MS=2

Hot Milk

left 10 0 0 OFF 0 0 100

B=0

M=1

MS=0

Hot water

− − − 100 − − − − −

Brewing temperature: 93°C Hot water dispensing: metered / not−

metered

Capacity of grounds container: 100 tablets Dampfausgabe: dosiert / undosiert

Steam boiler available: YES / NO Pump pressure: 8 bar

old: Voltage: 230 V / 400 V

new: E1-E2 locked / unlocked

Pressure-reducing valve in the

equipment: 2.6 bar

4-5

Service instructions bremer VIVA, issued 1997-07 Status: 2003-03

VIVA au lait −without adjustable milk dosage −customer’s settings

Article Grin-

der

left

centre

right

Grin-

der

lok-

king

posi-

tion

0-14

Groun

d cof-

fee

quan-

tity

0-999

app.

1/100 s

Bre-

wing

water

0-999

app. 0,5

ml / imp.

Bre-

wing

pres-

sure

OFF, ON

Bre-

wing

time

(only if

brewing

pressure

is ON)

Milk

froth

0-999

Milk

do-

sage

0-999

Dosing

se-

quence

B=bre-

wing

M=milk

MS= milk

foam

1, 2, 3,

0=Aus

Coffee

Cafe Crème

Espresso

Latte

Macchiato

Cappuccino

White coffee

Espresso

Macchiato

Hot Milk

Hot water

Brewing temperature: Pump pressure:

Grounds container capacity:

Steam boiler available:

Voltage / E1-E2 locked:

Hot water dispensing:

Customer: Coffee roaster:

Table of contents

Other Bremer Coffee Maker manuals