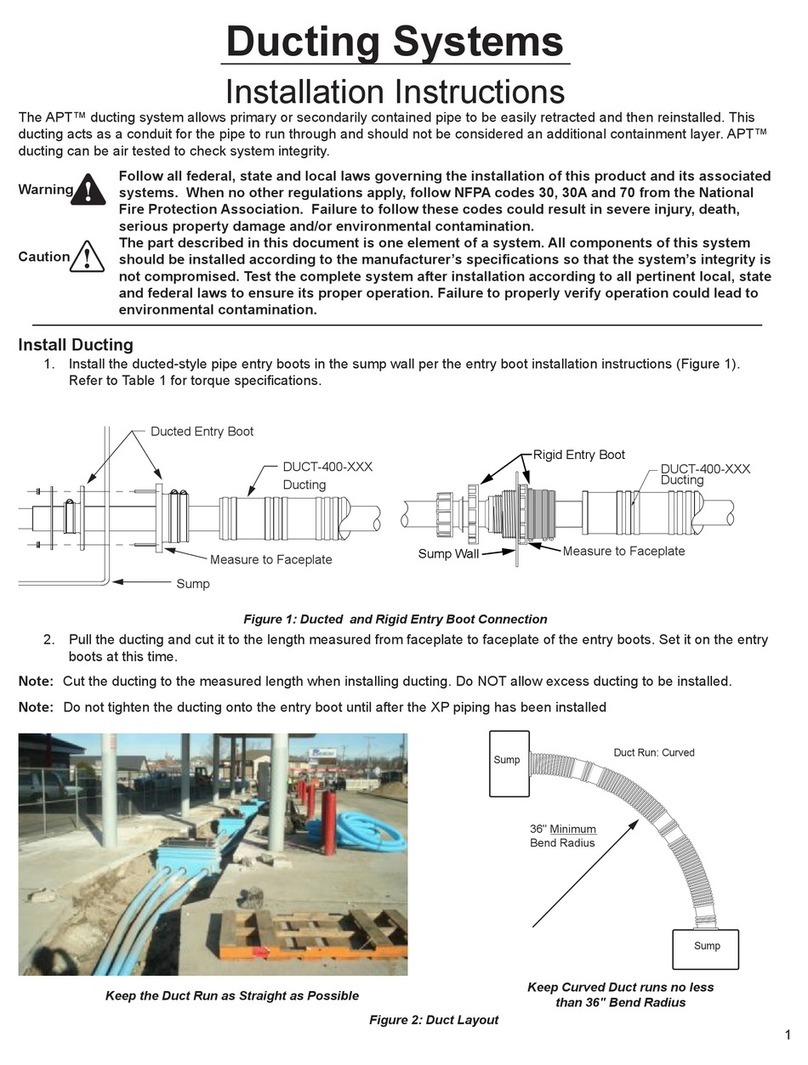

brent ie User manual

FOR ALL BRENT® POTTER’S WHEEL MODELS

owner’s manual

Approved

220-240V AC

2brentwheels.com

WARNING

LABELS AND

THEIR MEANING

Your new wheel may

have one or more of

these stickers applied to it.

Eletrical shock hazard

Disconnect power supplies

before servicing or cleaning

Requires two people

to lift safely

Requires three people

to lift safely

Do not hose

Electrical ground

TABLE

OF CONTENTS

CONTENTS Warning Labels and Their Meaning......................................................................................2

Your New Potter's Wheel.............................................................................................................3

Important Safety Information...................................................................................................4

General Information........................................................................................................................5

Potter's Wheels Chart.....................................................................................................................5

brent® ie and ie-x Potter’s Wheels Leg Installation............................................................6

Using Your New Wheel.........................................................................................................................6

Install thhe Splash Pan.........................................................................................7

How to Operate the Pedal................................................................................7

Caring for Your Wheel ...........................................................................................................................8

Maintenance: Replacing the Belt...................................................................................................8

Models: B, C, CXC, EX, and #16................................................................9-10

Models: ie, ie-r, and ie-x.............................................................................10-11

Maintenance: Slide Adjustment ..................................................................................................12

Maintenance: Wheel Motor Brush Replacement.......................................................13

Slow Blow Fuse Replacement and information.........................................................14

Troubleshooting .....................................................................................................................15-17

Parts Diagrams .................................................................................................................18, 20-21

Parts Lists .............................................................................................................................19-20, 22

Warranty Information..................................................................................................................23

Wheel Accessories ........................................................................................................................24

3800-999-5456

WELCOME

Congratulations on your purchase of a brent® Potter’s Wheel.

We trust you will be pleased with your decision and enjoy your new wheel for years to come!

DELIVERY

INSPECTION

PACKAGE

CONTENTS

Before signing the delivery receipt, thoroughly inspect your package. If merchandise is damaged, please

make notation of the damage on delivery receipt, stating that you request an inspection by a qualied

damage claim inspector. Follow up with a call to the delivering carrier, making an appointment for the

inspection. At this time notify AMACO/brent as to the extent of the damage and you will be informed

upon the procedures necessary for ling a claim with the freight company.

[1] Wheel and

Foot Pedal

[1] Plasti-bat

[1] Splash Pan:

two halves

YOUR NEW

POTTER'S WHEEL

Please read the enclosed safe operation, maintenance, and warranty information carefully.

Do not attempt to operate the wheel if damaged.

4brentwheels.com

IMPORTANT

SAFETY INSTRUCTIONS

DO READ AND SAVE THESE INSTRUCTIONS

NOTE: It is not safe to operate

electrical equipment around

water if it is not grounded.

DO AND

DO NOT

DO NOT leave wheel running unattended.

DO NOT force the wheel head to stop, as

this will shorten the life of the motor.

DO NOT plug power cord into an

extension cord.

DO plug power cord directly into electrical

wall outlet.

DO NOT exceed recommended maximum

clay weight for your wheel, to do so will

shorten the life of the motor.

DO fully depress foot pedal backwards

into the “OFF” position before turning

the wheel on.

DO NOT attempt to move or hold the wheel

during operation, or while the power is on as

this could cause serious injury.

DO when cleaning the wheel, inspecting

parts, and between periods of use, always

turn o the on/o switch and conrm that

the power indicator light is o. Then unplug

the wheel from its power source.

DO take care with long hair, jewelry, and

loose tting clothing. Such items may get

caught in the moving wheel head causing

damage or injury.

DO plug the wheel into a grounded

(3-prong) 110-120 or 220-240 volt AC

outlet, depending on your wheel’s power

conguration.

DO use an adaptor if you do not have

grounded outlets available. DO make

certain you connect the green wire from the

adaptor to a suitable ground.

DO NOT let the wheel stand in water.

DO keep tools and small parts out of reach of

small children.

DO place the wheel on a at, even surface

away from other objects.

DO NOT ever operate the wheel with the

belt guard removed.

DO NOT attempt to lift the wheel by yourself.

Equipment must be lifted by two to three

people, depending upon your wheel model.

DO when conducting a repair, disconnect

power supply by unplugging power cord

from outlet.

DO have the power outlet in the vicinity of

the wheel and under immediate supervision

of service personnel at all times.

DO stop operation of the wheel if you

see or smell smoke, or if you hear unusual

noises. Then turn o power, unplug power

cord from outlet, and call brent® Repair for

assistance.

DO NOT remove the control box and panel

covers when the wheel is plugged into

power. Doing so makes the internal parts

vulnerable to damage.

DO NOT attempt repairs and modications

yourself. To do so will void your warranty.

DO call a qualied technician for repairs or

modication. Should you need clarication

or help troubleshooting before calling a

technician, call AMACO/brent rst at 800-

999-5456 for help and technical support.

5800-999-5456

GENERAL INFORMATION

OF THE BRENT POTTER‘S WHEEL

The potter’s wheel was rst created around 3000BC as a means to increase production of ceramic

wares for everyday use. Though the concept is very simple, today’s machines add elegance and robust

engineering to meet the modern pottery demands.

The Brent potter’s wheel consists of a polished

aluminum head attached to a powder coated

steel frame that house the electronics, motor,

and pulleys that deliver all the torque needed to

shape clay into its nal form. The Brent potter’s

wheel is wrapped in a vacuum formed HDP sheet

for easy cleaning if any clay happens to make

it past the injection molded HDPE splash pan,

which acts as a basin for all your clay slurry that

formed during the throwing process. All of these

components help make Brent pottery wheels the

most dependable wheel on the market.

MODEL PART

NUMBER

WHEEL

HEAD HP WEIGHT VOLTAGE CURRENT FREQUENCY dB(A)

LBS KG

ie 22833M 12" 1/4 93 42 110-120V

10

50 - 60 Hz 70

22800X 12" 1/4 220-240V

ie-r 22897M 12" 1/4 93 42 110-120V

ie-x 22900R 14" 1/3 98 45 110-120V

22901P 14" 1/3 220-240V

B22604E 12" 1/2 112 51 110-120C

22606G 12" 1/2 220-240V

C22608J 14" 3/4 117 53 110-120V

22610L 14" 3/4 220-240V

CXC 22727G 14" 1 117 53 110-120V

22728H 14" 1 220-240V

EX 22573A 14" 1 1/2 119 54 110-120V 15

#16 22666E 12" 1/2 287 130 110-120V 5

22613P 12" 1/2 220-240V

GENERAL

INFORMATION

BRENT POTTER‘S

WHEELS CHART

6brentwheels.com

BRENT® IE AND IE-X

POTTER’SWHEELS LEG INSTALLATION

The wheel has an on/o switch, a fuse, and on

some models, a reversing switch located on the

right side of the wheel. Make sure the foot pedal

is in the “o” position before turning your power

switch on.

Occasionally, due to minor voltage variations, you

may need to adjust the foot pedal to achieve an

optimal calibration to your electrical environment.

(see Troubleshooting, pages 15-17)

Once you have carefully removed your wheel

from the carton, you will nd it is shipped in its

table-top conguration. It comes equipped with

a 9-foot cord for versatility.

1. Position the wheel on its back edge with the bottom facing you.

Do not allow the wheel to tip over as it may damage the wheel

head assembly.

2. Remove the end caps from the leg stubs of the wheel (this allows

the legs to be inserted into the leg stubs). Remove the foot pedal

and the three (3) legs from the attached box.

3. Insert a leg into one of the two bottom

leg cylinders of the main assembly until

fully seated. Using the 5/16" allen wrench

(provided) turn both set screws until they

make contact with the leg, then tighten each

screw another ¼ turn.

NOTE: Each leg comes with a cap plug

installed in the bottom. These plugs may

loosen during shipping, to reseat, tap them

lightly with a hammer.

4. Repeat step 3 for the remaining two legs

inserting the top leg last.

5. With the legs fully seated, the wheel is at the

industry standard height. If you prefer, you

may raise the wheel height by loosening the

set screws and pulling the legs out to the

desired length. Then retighten the set screws

as described in step 3.

NOTE: Ensure that all three (3) legs are set

to the same length so the wheel will sit level.

SHIPPED IN

TABLETOP

CONFIGURATION

CHANGING TO

FLOOR MODEL

CONFIGURATION

USING YOUR

NEW WHEEL

7800-999-5456

HOW TO

OPERATE

THE PEDAL

Tip the foot pedal towards you in the “OFF”

position and toggle the ON/OFF switch into

the “ON” position. The pilot light will come

on indicating that the solid state circuit that

controls the motor is receiving power. With the

foot pedal tipped back, the wheel head should

not rotate. As the foot pedal is pushed forward,

the speed should increase smoothly, up to a

maximum of 240 rpm. If the wheel does not turn

o with the foot pedal back, or does not run fast

enough, see Troubleshooting on pages 15-17.

All wheels except the ie model are reversible.

If you wish to reverse the direction, tip the foot

pedal toward you in the “OFF” position. When

the wheel stops, move the FWD/REV toggle

switch to either Forward or Reverse.

[ On ]

[ O ]

INSTALL THE

SPLASH PAN

USING YOUR WHEEL

FOR THE FIRST TIME

NOTE: The splash pan is

not meant to hold water.

NOTE: When starting up your wheel for the rst time, the wheel may have a slight “thump”

sound. This is normal and is a result of the rubber drive belt being held in the same position

since manufacturing and should go away within 10 or 15 minutes of use.

8brentwheels.com

CARING FOR

YOUR WHEEL

With proper care and

maintenance, brent® wheels

have been known to be in

service for over 30 years.

Please follow these

simple instructions to ensure

this kind of dependability

from your brent® wheel.

Turn o and unplug wheel when not in use.

To ensure maximum brush life, always

allow the motor to come to a complete

stop before changing directions of the

wheel head.

Clean wheel after every use by removing

splash pan and emptying contents into slop

bucket. Sponge down table and legs.

Clean oor of any surrounding water and

wet clay.

Store foot pedal on wheel table when not

in use. In addition, when mopping studio

oors, foot pedals should be placed on the

table top of the pottery wheel.

Always clean wheel with a damp sponge

and water, do not use solvents and do not

use a hose.

Do not let wheel stand in water or slop.

Store in a dry space away from outdoor

elements. If placing the wheel into storage,

it might be benecial to pull your motor

brushes from the motor with the wheel

disconnected from power, in order to avoid

problems that could arise otherwise.

Keep the serial number and the date of

purchase in a safe place: you will need this

information if you ever need service or want

to make modications to the wheel.

The recommended operating and storage

temperatures is 50-90° F, with a relative

humidity of less than 60%.

Keep the wheel away from dust and

vibration during storage to ensure

maximum life of the wheel.

MAINTENANCE:

REPLACING

THE BELT

To ensure correct belt tension and maximum

belt life, all our belt drive wheels come equipped

with automatic belt tensioning devices. The

spring tensioner will eliminate having to tighten

the belts. It’s not necessary to release the spring

tensioner when removing the belt, simply roll the

belt o the pulley. Check belts every ve years

for wear as the rubber will break down faster in

some climates. To replace the belt, please follow

instructions for your particular wheel on either

page 9-10 or 10-11.

TAKING CARE

OF YOUR WHEEL

9800-999-5456

MAINTENANCE:

STANDARD BELT REPLACEMENT

1. Turn wheel o and unplug from the power

outlet. Raise the front of the pottery wheel

until the wheel rests on its back legs.

3. Gently pull the top of the belt guard toward

you and twist it to the left. Set belt guard

aside.

2. Locate the belt guard on the bottom of the

wheel. Use a 7/16" wrench to remove the

three nuts and bolts highlighted in photo.

4. ‘Walk” the belt o the large pulley by

grabbing hold of the belt in the space

between the pulleys, then gently pull toward

you while turning the large pulley slowly.

MODELS:

B, C, CXC,

EX, and #16

5. Install new belt by tting the new belt over

the small pulley rst.

6. Lay one half of the grooved side of the belt

on the large pulley and start turning the belt

and pulley at the same time to “roll’ the belt

onto the large pulley.

10 brentwheels.com

7. Check that the belt is centered on both

pulleys. NOTE: It is common for the pulleys

to have more grooves than the belts.

8. Place the belt guard back in position

and attach with the three nuts and bolts

removed in step 2.

MAINTENANCE:

STANDARD BELT REPLACEMENT

MODELS:

B, C, CXC,

EX, and #16

continued

MODELS:

IE, IER,

and IEX

1. Turn wheel o and unplug from the power

outlet. Raise the front of the pottery wheel

until the wheel rests on its back legs.

3. Remove the belt guard panel and set aside.

2. Locate the belt guard panel on the bottom

of the wheel. Use a 1/4" socket screwdriver to

remove the four screws highlighted in photo.

4. ‘Walk” the belt o the large pulley by

grabbing hold of the belt in the space

between the pulleys, then gently pull toward

you while turning the large pulley slowly.

11800-999-5456

MAINTENANCE:

STANDARD BELT REPLACEMENT

MODELS:

IE, IER,

and IEX

continued

5. Install new belt by tting the new belt over

the smaller motor pulley rst.

7. Check that the belt is centered on both

pulleys. NOTE: It is common for the pulleys

to have more grooves than the belts.

6. Lay one half of the grooved side of the belt

on the large pulley and start turning the belt

and pulley at the same time to “roll” the belt

onto the large pulley.

8. Place the belt guard panel back in position,

then attach with the four screws removed in

step 2.

12 brentwheels.com

MAINTENANCE:

SLIDE ADJUSTMENT

MODEL:

No. 16

1. If there is side play in the wheel or the slides

are too tight for ease of height adjustment,

troubleshoot the problem by rst removing

the acorn nuts.

2. Using the allen wrench and the open-end

wrench, hold the set screw in place and

loosen the lock nuts. Adjust the set screws,

either left to loosen or right to tighten. Do

this systematically to all set screws until the

slides have proper tension.

3. Turn the handle and check to ensure

that the problem has been solved. If not,

continue the process of systematically

adjusting the set screws. When there is

proper tension on the slides and the handle

easily adjusts the height of the wheel

without side play, tighten the lock nuts and

thread the acorn nuts back into place.

Lock Nut

Set Screw

Open-end

Wrench

Allen

Wrench

Acorn Nut

13800-999-5456

MAINTENANCE:WHEEL

MOTOR BRUSH REPLACEMENT

1. Carefully remove the brush cover using a

standard at-blade screwdriver or washer.

3. Gently pull the brush out of the holder.

Note orientation of brush to ensure you can

replace in same way if brush will be re-used.

5. Use brush cover to compress brush spring.

The two tabs of the brush must be aligned

properly in the holder.

CURRENT

ELECTRIC

MOTORS

2. Once the cap is removed, the brush spring

will be visible.

4. For installation, insert the brush into the

holder.

6. Use your ngers or a screwdriver to thread

brush cover into holder. Be careful not to

strip plastic threads. DO NOT OVER TIGHTEN.

Motor brushes should be replaced every 5000

hours of operation. This equates to a standard

use of 4 hours per day, 5 days per week for

5 years. Please contact AMACO/brent FIRST

when your brushes need replacing. Please email

technicalsupport@amaco with a photo of your

old brush, the serial number of your wheel and

make of motor so the technician may help you

choose the correct brushes for your wheel.

Your replacement brush may come from

AMACO/brent or your local distributor.

CAUTION: UNPLUG THE POWER

BEFORE ATTEMPTING MOTOR SERVICE!

14 brentwheels.com

SLOW BLOW FUSE

REPLACEMENT AND INFORMATION

The slow blow fuse is located near the power

switch on the side of the ie series wheels. Push

and turn the cap labeled “fuse” to remove. The

cap should come out easily with the slow blow

fuse attached. Pull on slow blow fuse to remove

from cap. Refer to chart for replacement slow

blow fuse. Push the cap in and turn to lock the

new slow blow fuse into place.

FUSE LOCATION

MODEL VOLTAGE FUSE TYPE SLOW BLOW

ie 110-120V 6 Amp Slow Blow

220-240V 6 Amp Slow Blow

ie-r 110-120V 6 Amp Slow Blow

ie-x 110-120V 6 Amp Slow Blow

220-240V 6 Amp Slow Blow

B110-120C 20 Amp Slow Blow

220-240V 25 Amp Slow Blow

C110-120V 20 Amp Slow Blow

220-240V 25 Amp Slow Blow

CXC 110-120V 20 Amp Slow Blow

220-240V 25 Amp Slow Blow

EX 110-120V 25 Amp Slow Blow

#16 110-120V 20 Amp Slow Blow

220-240V 25 Amp Slow Blow

REPLACING

THE SLOW

BLOW FUSE OF

MODELS:

B, C, CXC,

EX, and #16

REPLACING

THE SLOW

BLOW FUSE OF

MODELS:

IE, IER, and IEX

SLOW

BLOW FUSE

INFORMATION

All slow blow fuses are

1.25" x .25" or 6.35 x 31.75mm

CAUTION: UNPLUG THE POWER PRIOR

TO REPLACING THE SLOW BLOW FUSE!

Remove (4) screws from the power cable side

of the control box. The slow blow fuse will be

behind the cover. Carefully remove the slow blow

fuse, a tool may be needed to gently pry the slow

blow fuse out of the socket.

15800-999-5456

TROUBLESHOOTING

1. Remove bottom of pedal. Check plastic arm to see if it is tight on the bolt that runs through it.

If it is not, push plastic arm to the bottom of pedal and tighten the set screw in the base of

the arm. [ Fig A ]

2. Turn the blue “LO” disc clockwise until wheel head stops rotating. [ Fig B ]

The following is a list of the most common concerns that may be experienced while using your brent®

potter’s wheel. Most of these diculties occur as a result of normal “wear and tear” and can be solved

with ease. Our brent® wheels have up to a ten year warranty on in-house service and parts.

If you have any questions or need to order replacement parts,

contact the AMACO/brent Technical Support Department at 800-999-5456.

AB

1. Ensure that the direction switch is not in neutral, if this does not solve the problem continue

to step 2.

SWITCH POSITIONS: Reverse / Neutral / Forward

2. Disconnect from the power supply.

3. Check the fuse and replace if blown. (see page 14)

4. If there is power to the control box and the fuse if ne, please call brent repair for assistance.

Note: Always unplug your wheel when it is not in use to protect

against power surges and lightning storms.

WHEEL HEAD

STILL ROTATES

WHEN PEDAL

IS OFF

WHEEL DOES

NOT ROTATE

WHEN POWER

IS ON

16 brentwheels.com

TROUBLESHOOTING

(continued)

1. Lean the wheel back so that it is lying

securely on its back.

2. Loosen the two bolts which hold the

guard in place.

3. Adjust the guards until rubbing stops.

4. Tighten bolts.

5. If problem persists, please call brent® Repair

for assistance.

BELT IS RUBBING

AGAINST THE

BELT GUARD

(not applicable for ie models)

FOOT PEDAL IS

TOO LOOSE OR

TOO TIGHT

1. Use a ½” size wrench to tighten or loosen the

nut on the side of the foot pedal, as needed.

The belt is o its pulleys or has broken.

1. Disconnect the power supply.

2. Lean wheel back so it is resting securely on

its back legs.

3. Remove belt guard.

4. Place belt in middle grooves of small pulley

on motor.

5. Start belt on large pulley, then rotate large

pulley until belt is on.

6. Turn wheel on and test to make sure belt

stays on. (If belt continues to fall o, call

brent® Repair for assistance.)

7. Reinstall belt guard.

WHEEL HEAD IS

NOT ROTATING,

BUT THE MOTOR

IS RUNNING

17800-999-5456

1. Turn foot pedal over and remove the bottom plastic cover from the pedal.

2. Locate the red disc, this is the “HI” speed adjustment.

3. Using a small standard screwdriver, rotate the red disc clockwise to increase the speed, or counter-

clockwise to decrease the speed.

4. Any adjustments to the red disc may result in having to make an adjustment to the blue disc.

If you increase the overall speed of the wheel, you may have to turn the blue disc clockwise to

make the wheel stop when the pedal is moved to the o position, If the wheel speed is decreased,

you may have to turn the blue disc counter-clockwise to increase the range of motion when the

foot pedal is moved to the o position.

“HI” Adjustment

(Red Disc)

“LO” Adjustment

(Blue Disc)

Note: The discs are very sensitive and will require very little movement, 1 to 5 degrees at a time.

The wheel can be on and rotating while making this adjustment to ensure that the start point

is at the desired speed.

TROUBLESHOOTING

(continued)

WHEEL HEAD

ROTATES

TOO FAST

OR TOO SLOW

Please note that if your screwdriver touches the silver tabs between the red and blue discs,

while the wheel is connected to power, this could result in a blown circuit board.

18 brentwheels.com

PARTS

DIAGRAM

MODELS:

B, C, CXC,

EX, and #16

Match circled numbers

on this page to item

numbers on pages 19-20

for part description.

19800-999-5456

PARTS LIST

Parts list continued on page 20.

ITEM # QTY. PART # DESCRIPTION

32331K for Models B, 16

1 1 32333M for C, CXC & EX Models Plasti-Bat

2 2 22135X Bat Pin

3 2 Item 2 & 3 sold as set Bat Pin Wing Nut

22012M for B, 16

4 1 22017T for C, CXC & EX Models Wheel Head Assembly

4a 1 4a, 4b & 4c sold as assembly only see item 4 Wheel Head

4b 1 4a, 4b & 4c sold as assembly only see item 4 Wheel Head Shaft & Bearing

4c 1 4a, 4b & 4c sold as assembly only see item 4 Bearing Housing

5 3 5/16-18 x 1 1/4 Hex Bolt Wheel Head Mounting Bolt

6 3 5/16 Flat Washer Wheel Head Mounting Flat Washer

7 3 5/16 Lock Washer Wheel Head Mounting Lock Washer

8 3 5/16-18 Hex Nut Wheel Head Mounting Nut

9 1 22281F Splash Pan Front

10 1 Items 9 & 10 sold as a set Splash Pan Back

11 1 22279D Table Top Plastic

12 1 22426W Steel Frame and Legs

13 1 22048J Large Drive Pulley

14 1 5/16-18 x 5/8 Square Head Drive Pulley Lock Bolt

15 1 3/16 x 1 1/4 Key Stock Drive Pulley Shaft Key

16 1 22926W Drive Belt

17 1 22570W Belt Guard

18 4 22307N Belt Guard Vibration Snubber

19 1 1/4-20 x 3/4 Hex Bolt Belt Guard Bolt

20 1 1/4 Lock Washer Belt Guard Lock Washer

21 1 1/4-20 Hex Nut Belt Guard Nut

22 1 08671C Motor Mounting Plate

22228N for B, 16 Wheels 22767G for C Wheel

23 22227M for CXC Wheel 22786F for EX Wheel Motor

24 1 22637V (set screw included) Motor Drive Pulley (Small Pulley)

1/4-20 x 1/4 Allen Set Screw (included with motor

25 1 pulley part # 22637V)

26 1 5/16-18 x 5 Carriage Bolt Drive Belt Tension Bolt

27 1 5/16 Flat Washer Drive Belt Tension Bolt Flat Washer

28 1 5/16 Lock Washer Drive Belt Tension Bolt Lock Washer

29 1 5/16 Hex Nut Drive Belt Tension Bolt Nut

30 1 5/16-18 Wing Nut Items 30, 31 & 32 Used for shipping only

31 1 5/16 Lock Washer Items 30, 31 & 32 Used for shipping only

32 1 5/16 Flat Washer Items 30, 31 & 32 Used for shipping only

33 1 22286L Items 33 & 35 sold as set Tension Spring Guide Rear

34 1 22178B Tension Spring

35 1 22286L Items 33 & 35 sold as set Tension Spring Guide Front

36 1 5/16 Fender Washer Drive Belt Tension Bolt Fender Washer

37 1 5/16 Lock Washer Drive Belt Tension Bolt Lock Washer

38 1 5/16-18 Hex Nut Drive Belt Tension Bolt Hex Nut

39 2 1/4-20 x 2 Carriage Bolt Motor Mounting Plate Bolt

40 4 22306M Motor Mounting Plate Bushing

41 2 1/4 Fender Washer Motor Mounting Plate Fender Washer

42 2 1/4 Lock Washer Motor Mounting Plate Lock Washer

43 2 1/4-20 x 2 Carriage Bolt Motor Mounting Bolt

MODELS:

B, C, CXC,

EX, and #16

20 brentwheels.com

ITEM # QTY. PART # DESCRIPTION

45 4 Used for Manufacturing Only Motor Mounting Bolt Retainer

46 8 22306M Motor Mounting Bushing

47 4 1/4 Fender Washer Motor Mounting Fender Wsher

48 4 1/4 Lock Washer Motor Mounting Lock Washer

49 4 1/4-20 Hex Nut Motor Mounting Hex Nut

50 3 22695P Frame Leg Plug

51 2 1/4-20 x 3/4 Hex Bolt Belt Guard Bolt

52 2 1/4 Lock Washer Belt Guard Flat Washer

53 2 1/4 Flat Washer Belt Guard Lock Washer

54 2 1/4-20 Hex Nut Belt Guard Hex Nut

22906Y for Models B, 16 22907A for C Model

55 1 22908C for CXC Model 22912F for EX Model Classic Controller

56 1 Please call for prices and availability Power Cord for Classic Controller

57 1 Please call for prices and availability Power Switch for Classic Controller

58 1 Please call for prices and availability Reversing SwitchClassic Controller

59 2 1/4-20 x 1 Phillips Head Machine Screw Controller Mounting Bolt

60 2 1/4 Star Washer Controller Mounting Star Washer

61 2 1/4-20 Nylok Nut Controller Mounting Nylok Nut

62 1 22035R Foot Pedal Complete

63 1 22278C Foot Pedal Cover

63 1 22858R Electric Sub-assembly for Foot Pedal

63 1 22881S Foot Pedal Tension Hardware & Arm

64 4 22273W (Mtg. Screws Included) Foot Pedal Foot

65 4 6/32 X 3/8 Phillips Head Machine Screw Foot Pedal Foot Mounting Screw

66 1 22945T Foot Pedal Cord

ITEM # QTY. PART # DESCRIPTION

1 1 22508S Frame, 16 Complete

2 2 22851G Arm Supports

3 1 22849F Crank Assembly

4 1 22935H Belt Guard

5 1 22823B Foot Lever with Lever

6 1 22818T Foot Pedal Mounting Bracket

7 4 22847C Caster

8 4 22846D Adjusting Foot

PARTS LIST

MODELS:

B, C, CXC,

EX, and #16

(continued)

MODEL #16

ADDITIONAL

PARTS

MODEL #16

DIAGRAM

This manual suits for next models

6

Table of contents

Popular Other manuals by other brands

Wallenstein

Wallenstein BX36S operating manual

Painless Performance Products

Painless Performance Products 10106 installation instructions

Time Machines

Time Machines TM2000A Installation and operation manual

Compac

Compac CRK4 instruction manual

Arnott

Arnott C-2242 installation manual

Promag

Promag MP2 manual