Error Compensation

Direction

Radius / Diameter

SETUP, Radius / Diameter, Direction, Error Compensation C70 Digital Readout System

NOTES

The Diameter setting is

useful for lathes, and

other turning

applications, to display

diameter rather than

radius.

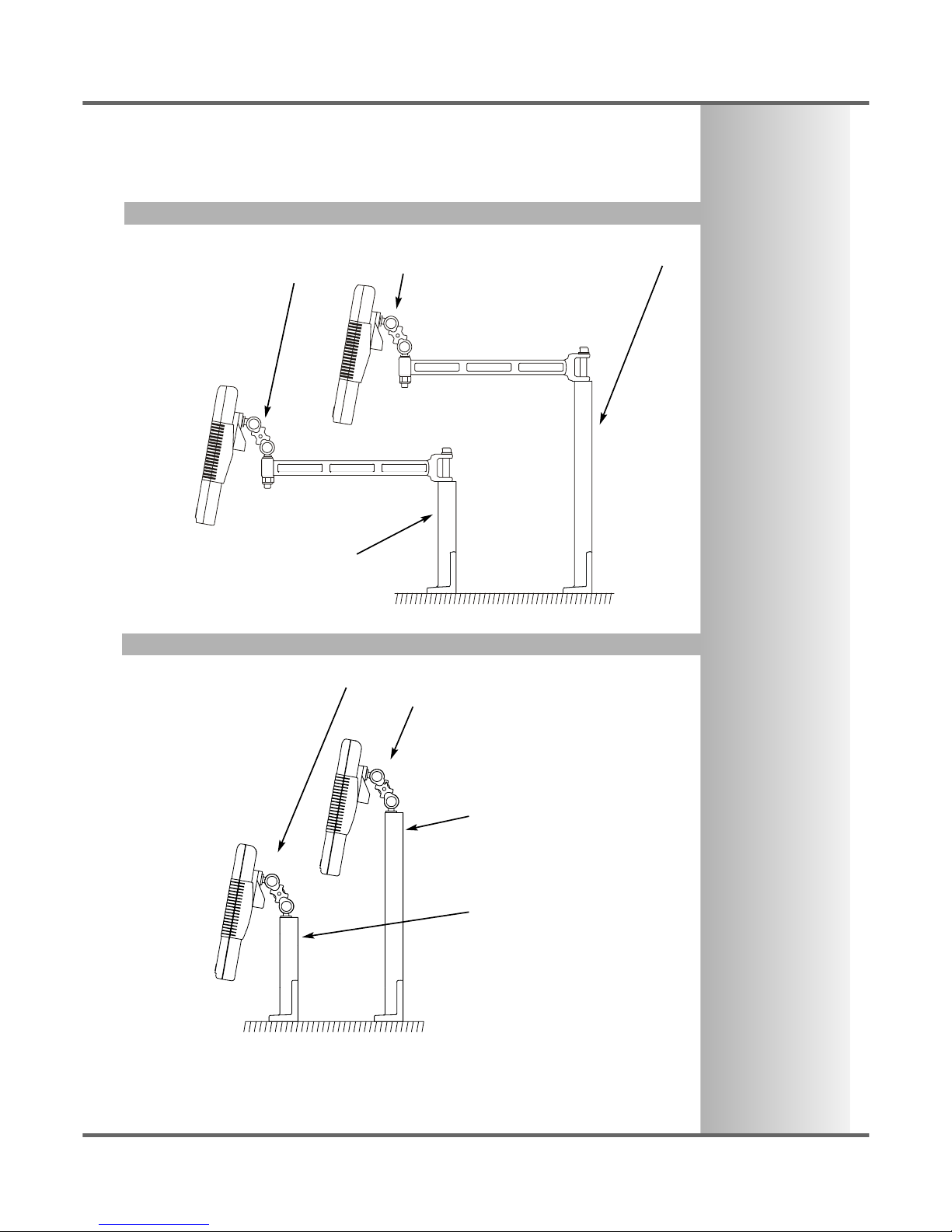

The Direction setting is

quite arbitrary. Set it to

whichever makes most

sense to the machine.

NB, Direction is

dependent on where the

scale is mounted

If Error Compensation is

applied, it is important

that is absolutely correct.

If it is not correct, errors

could be increased rather

than reduced.

After setting up the Error

Compensation, it is

advisable to check its

effect in normal

operation.

Segmented

Compensation need not

be over the entire scale

length.

It can be applied just to a

length of high

importance, or it can be

as small as one segment.

Newall Measurement Systems Ltd10

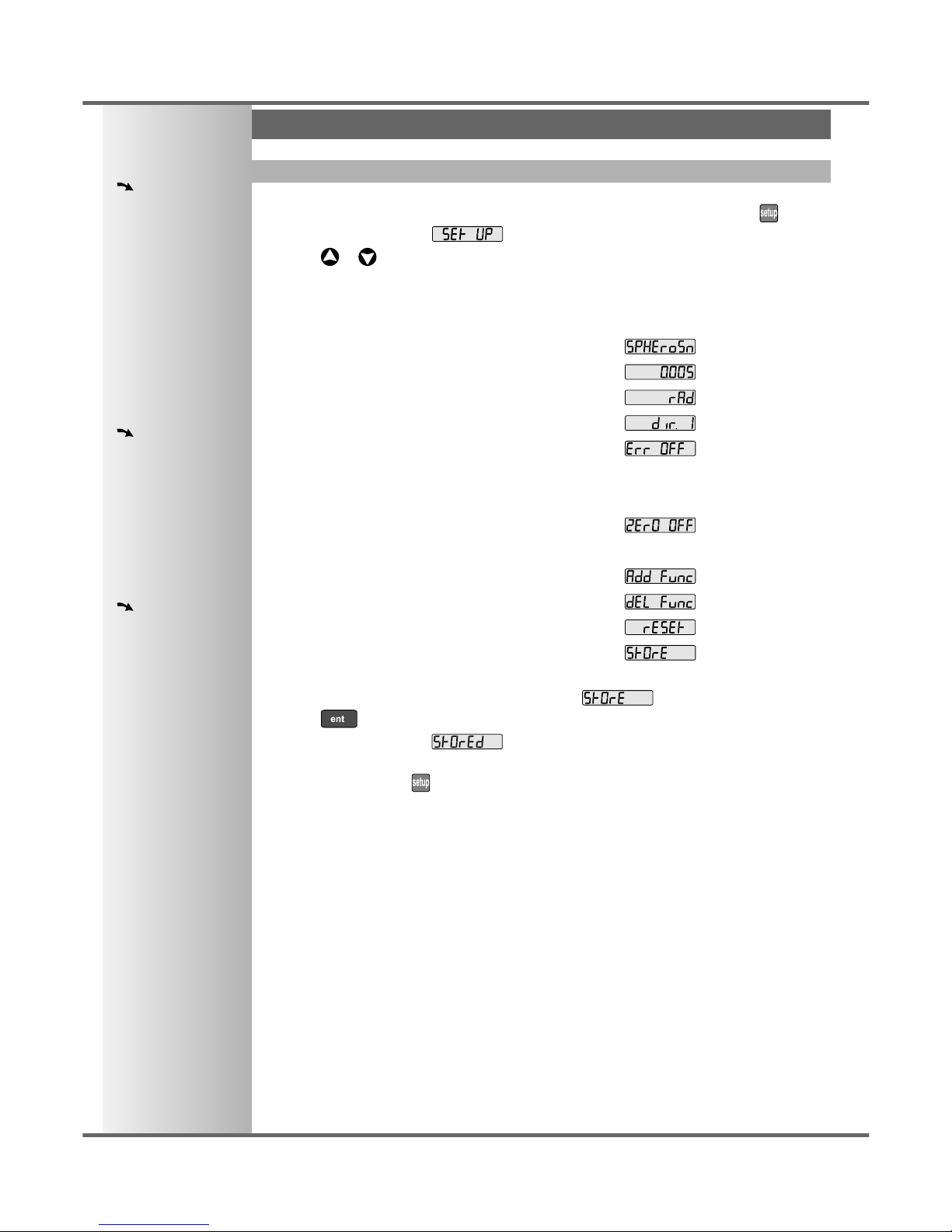

Selecting the Diameter setting causes the C70 to display double the actual movement on any axis.

There are two possible settings for each axis:

Radius

Diameter

•Press the Select Key next to the , or to cycle between the two settings for each axis.

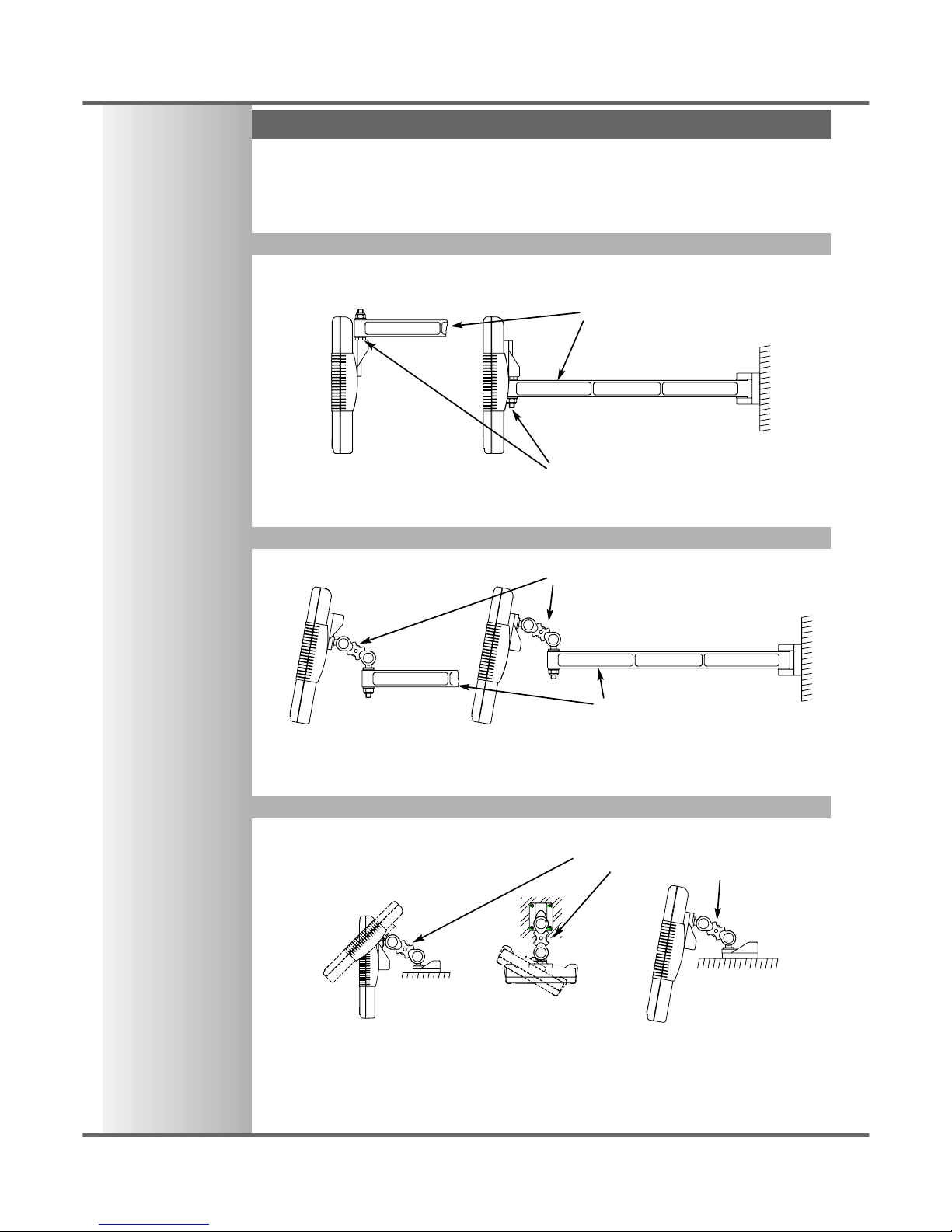

The Direction setting allows you to match the C70 to the actual direction of travel of any axis.

There are two possible settings for each axis:

•Press the Select Key next to the , or to cycle between the two settings for each axis.

Errors can result from a number of sources, including machine wear. Where the degree of error increases

linearly along the length of travel of the scale, Linear Error Compensation should be applied. However,

where the errors are local to an area of travel, the Segmented Error Compensation should be applied.

There are three possible settings for each axis:

Off

Segmented Compensation

Linear Compensation

•Press the Select Key next to the , or to cycle between the three settings for each axis.

If one or more axes are set to Segmented Error Compensation, or Linear Error Compensation, then

the next setup option will be to configure the compensation for each of those axes.

•Press .

The middle display changes to .

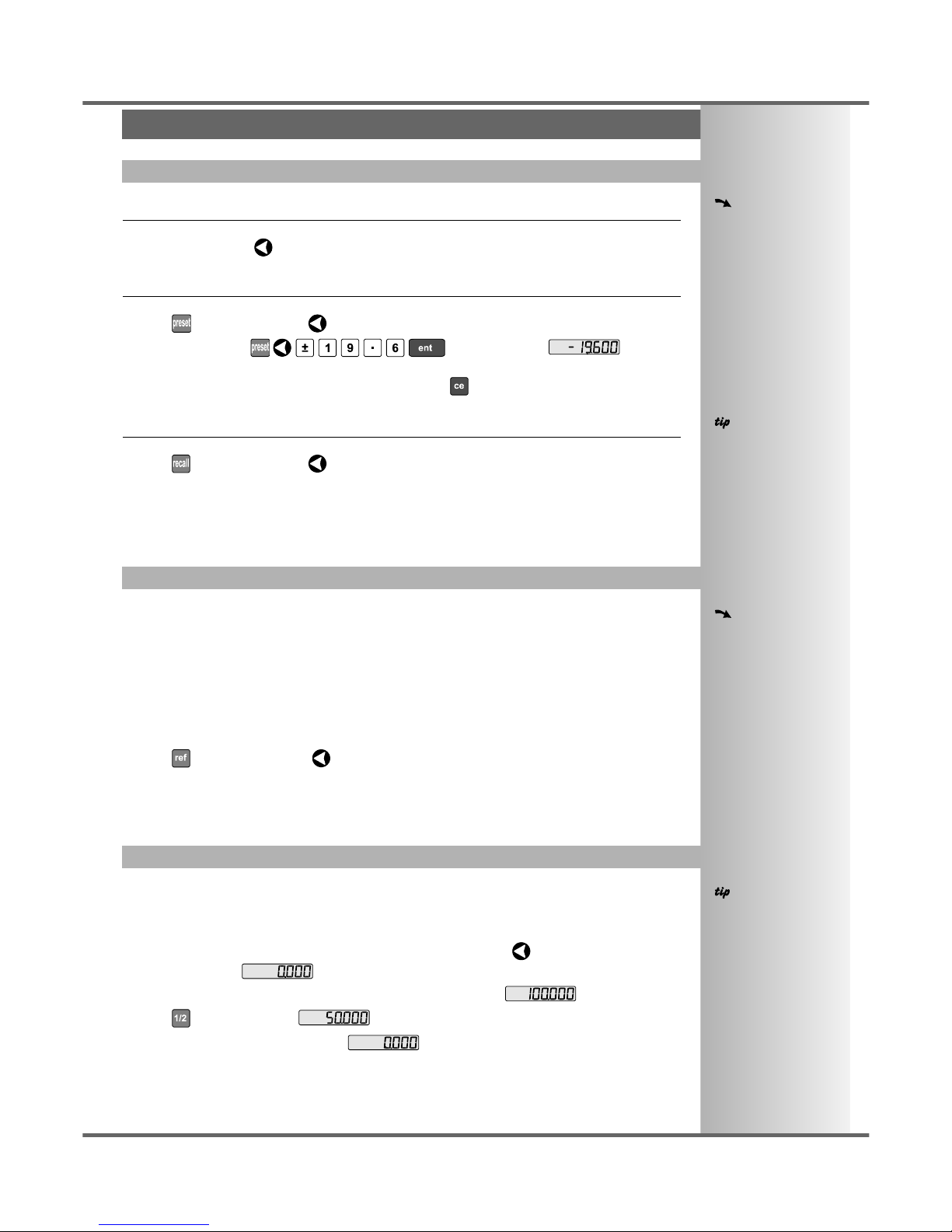

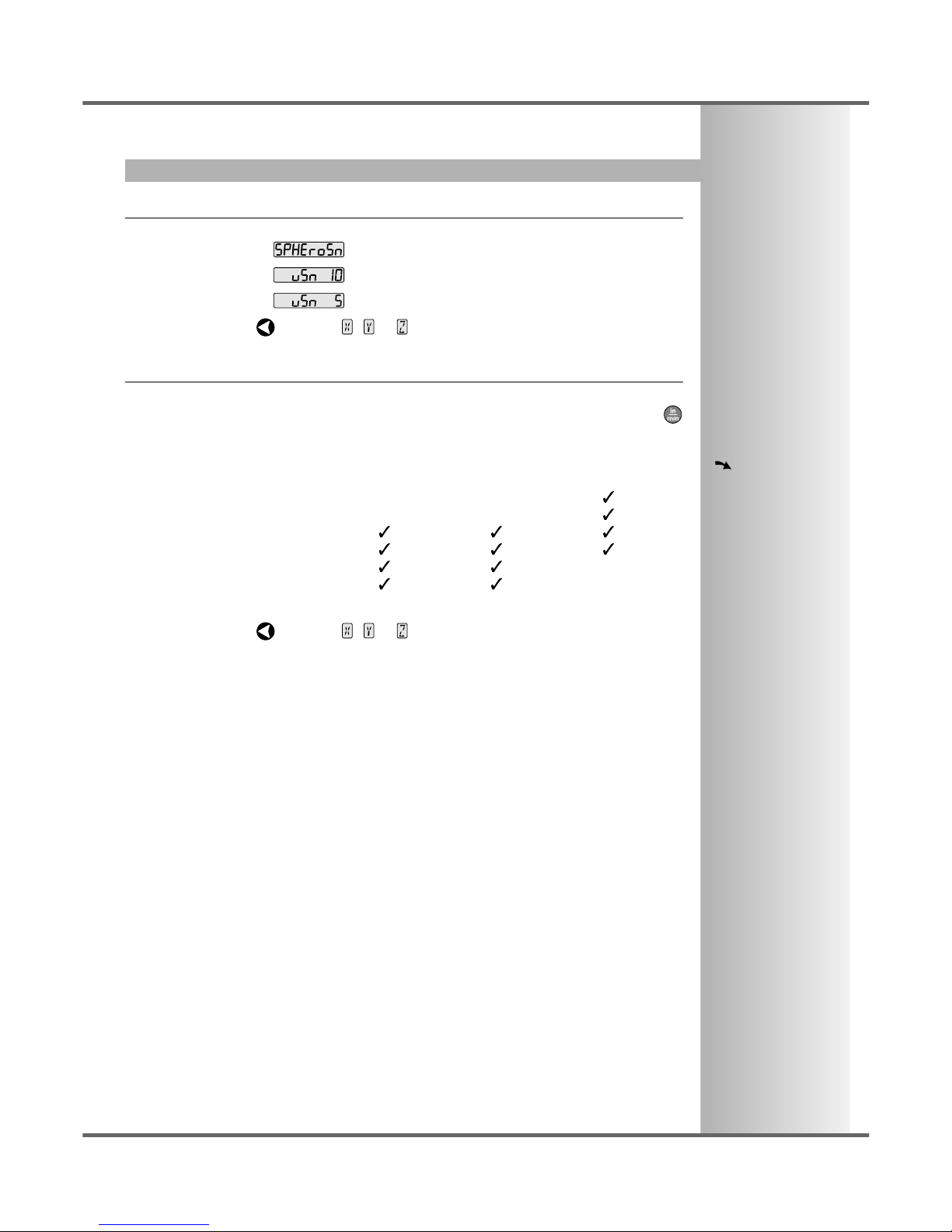

Segmented Error Compensation

In this mode, the scale travel for each axis can be broken down into as many as 99 user-defined

segments, with each segment having its own correction factor. The correction factors are calculated by

the C70 by comparison against known, user-supplied standards.

•When power is applied, the display for any axis that is set to use Segmented Compensation

shows .

•If the machine has not been moved since the power was turned off, simply press , and the C70

will restore the last positions recorded.

•Alternatively, set each axis close to the Reference Point - to within:

6.3mm (0.25”) for a Spherosyn encoder or

2.5mm (0.1”) for a Microsyn encoder,

and press the Select Key next to the , or . The C70 will re-establish alignment with the

correction parameters.

Linear Error Compensation

In this mode, a single constant correction factor for each axis can be applied to all displayed

measurements. The correction factor is calculated by the user, and specified in parts per million (ppm).

Values between -9999 and +9999 are allowed.

See pages 11 and 12 for details

on using Linear and Segmented

Error Compensation