GB INSTRUCTION MANUAL

BR-CR1

Ceiling rail system

with pantographs

Art. No. F000224

GENERAL SAFETY INSTRUCTIONS

ATTENTION!

• The assembly must be carried out by a qualied tter! It is

recommended that two people carry out the assembly.

• The ceiling rail system may only be attached to ceilings with an

appropriate load-bearing capacity!

•

The structure of the ceiling must be suitably solid and suitable for

the subsequent total weight (including attached pantographs and

accessories). Never mount the ceiling rail system on a wooden ceiling

or an unstable or suspended ceiling!

• Always ensure that the mounting screws are properly anchored!

Note: Information on the weight of the ceiling rail system can be

found in the chapter "Technical data". The weight specications for

other possible add-on parts can be found in the operating instructions

supplied with these parts.

DANGER FROM FALLING OR DROOPING PARTS!

•

Make sure that the ceiling rail system is securely and stably mounted

before attaching other device accessories* to it.

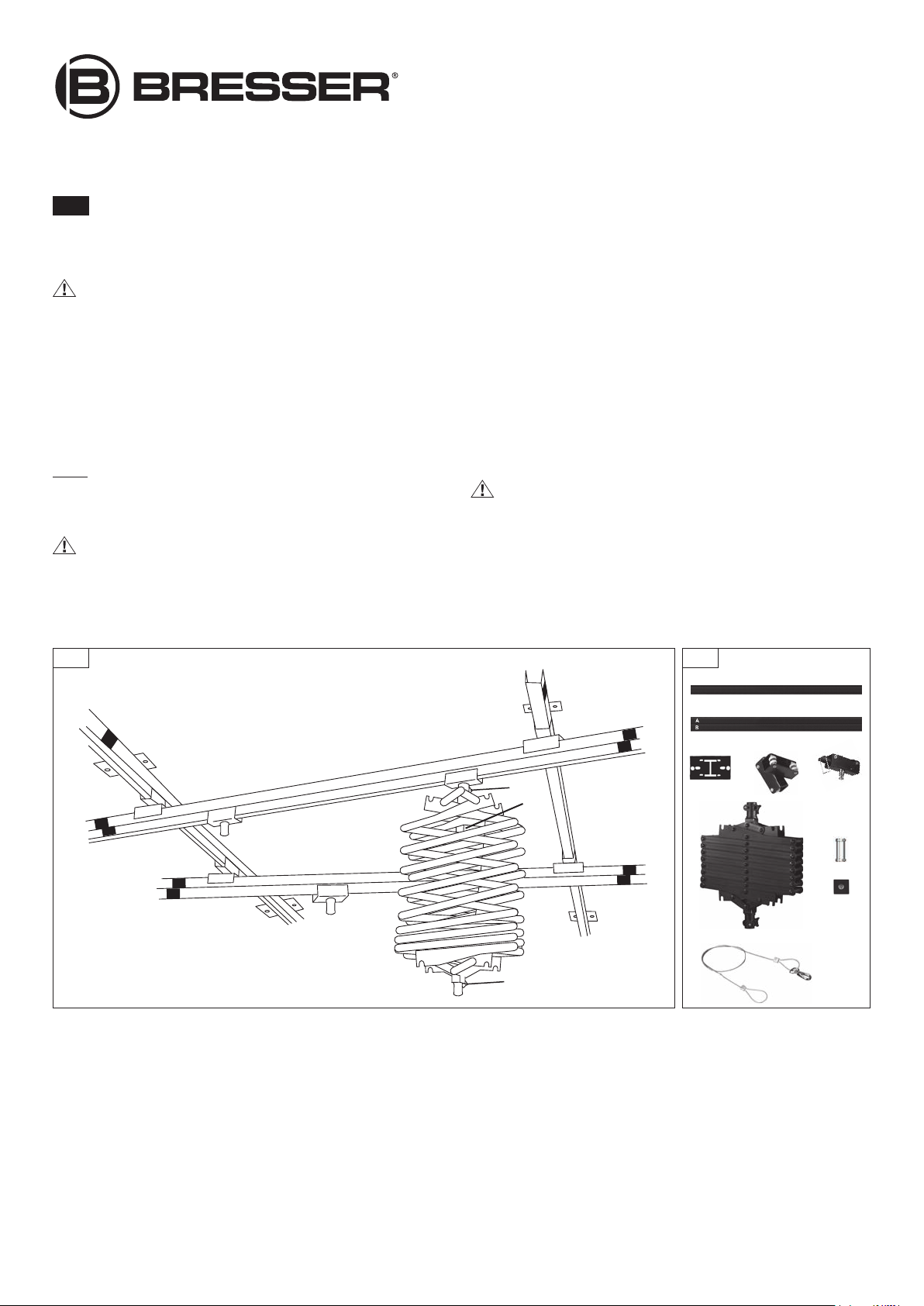

• Secure all devices/accessories* mounted on the pantographs using

safety wire rope.

• Lay the voltage and connection cables in such a way that they cannot

be damaged by the trolleys or cause strangulation to persons!

• Only use accessories that meet the required specications. Find

more information in the chapter "Technical data".

• The maximum total load capacity of the ceiling rail system must

not be exceeded. At the maximum total load capacity, both the total

system weight and the weights of the mounted accessories/devices*

must be taken into account. Find detailed information on weights

under "Technical data" as well as in the manual of the mounted

accessory.

DANGER OF CRUSHING!

• Do not touch the guide rails during assembly, cleaning, operation

and when changing the position or moving the current collectors!

• Do not insert ngers into the lifting mechanism of the pantograph!

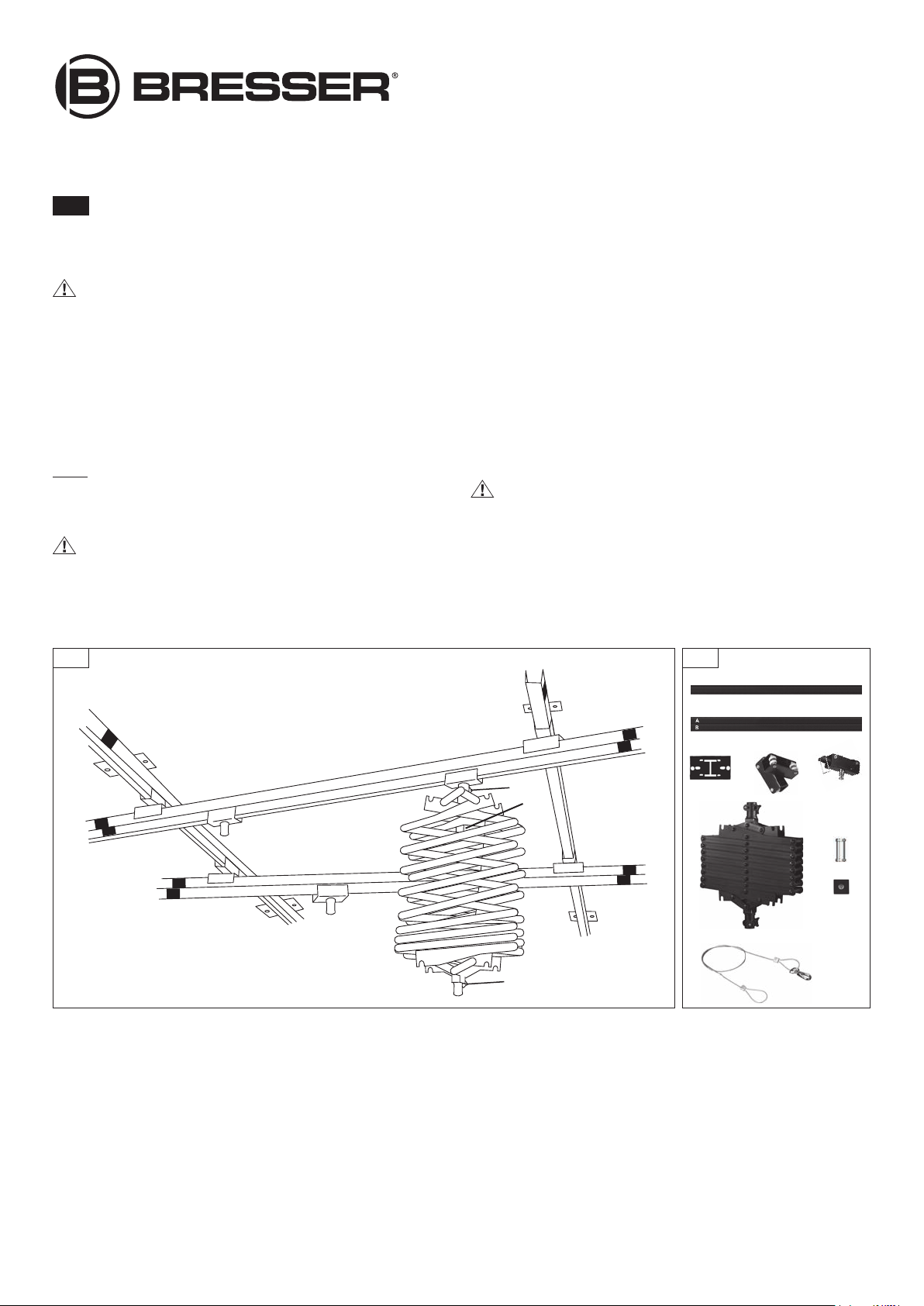

PARTS OVERVIEW (Fig. 1)

Single slide rails Double slide rails Ceiling brackets Double carriage roller Single carriage roller (with integrated spigot connection)

Pantograph Spigot adapter Rail stopper Safety wire rope Knob screw

SCOPE OF DELIVERY (Fig. 2)

2x single slide rails 2x double slide rails Ceiling bracket (4x) Double carriage roller (4x) Single carriage roller (4x) Pantographs (4x)

Spigot adapter(4x) Rail stopper (12x) Safety wire rope (4x)

ADDITIONALLY REQUIRED*

Phillips screwdriver, 8 pcs. mounting screws (type M6) and, if necessary, suitable dowels/ceiling anchors for mounting the ceiling brackets

*not included with the purchase

Fig. 1 Fig. 2