BREWHA Equipment Co Ltd. ETC120 User manual

ETC120 TEMPERATURE CONTROLLER

INSTRUCTION MANUAL Version 1.0

BREWHA Equipment Co Ltd. www.brewhaequipment.com

2017.1 P1/3

1. Overview

This temperature controller contains one temperature probe and

two independent outputs. One output is for cooling and the other

one is for heating. It can be used for applications such as heating

during mashing or fermentation or for cooling post-boil and

during fermentation.

This controller is a plug and play controller. No wiring is needed

for the heater or cooler. Both the heating and cooling control

modes are simple on/off control similar to a mechanical

thermostat but with much higher precision due to an adjustable

hysteresis band precise sensor and digital read out. Anti-short

function is also provided for cooling to protect a refrigerator

compressor from being turned on while at high pressure which

could damage it.

Different operation temperature ranges of the two outputs can be

set separately. Once the cooling range is set the controller

program will automatically limit the heating range to prevent both

heating and cooling from being turned on at the same time.

A digital silicon band gap sensor is used with the advantage being

that it is much more reliable in a moist environment than a

thermistor sensor. It can be immersed over an extended period of

time. It also has more uniform accuracy over an entire specified

temperature range.

2. Specification

SET

4. Setup Flow Chart

When the controller is plugged in and the probe is attached it

will display the measured temperature. The controller will keep

running according to the saved settings. If the temperature

sensor is shorted or removed the controller will display “Err”.

Please see Figure 2 for the flow chart to set the parameters.

Up Key

Dn Key, Mute Alarm

Set Key

Measured

Temperature

Receptacle for

Cooling Device

Receptacle for

Heating Device

Heating device

n Indicator

Cooling Device

n Indicator

3. Front Panel

Figure 1. Front Panel

68.9

5 sec

SET

HSP

SET

AH

SET

AL

SET

CDF

SET

HDF

AS

SFA

FS

C-F

SET

SET

SET

SET

SET

68.9

SET

Figure 2

Set Up Flow Chart

Alarm High Limit

Alarm Low Limit

Cooling Differential

Heating Differential

Cooling Antishort

Sensor Failure

peration

Temperature ffset

Temperature Unit

Displayed Temperature Cooling

Set Point

Heating

Set Point

CSP

Sensor Probe Connector

120V/12A Power Cord

Temperature Control Range -2 to 105ºC/28 to 221ºF

Resolution 0.1º (from -9.9 to 99)

Accuracy 0.5ºC/0.9ºF

Control Mode On/Off Heating and Cooling

Control Output 12A/120V

Audio Alarm High and Low Limit

Sensor Type Silicon Band Gap

Sensor Size 6mm/0.25”OD by 100mm/4”

Measuring Range -2ºC/28ºF to 105ºC/221ºF

Ambient Temperature -20ºC/-4Fº to 50ºC/122ºF

Dimension 91x140x46mm

3.5x5.5x1.75”

Input Power 15A/110-120V/60Hz

Sensor Cable Length 2.4m/8’

Power Cable Length 1m/3’

Warranty 1 year

BREWHA Equipment Co Ltd. www.brewhaequipment.com

2017.01 P2/3

5. Parameter Settings

To change the temperature set point press the SET key

momentarily. The controller will show CSP (Cooling set point)

pressing SET again will show HSP (heating set point). When the

controller shows CSP or HSP use the Up or Down keys to change

the value. Then press the SET key again to confirm the change.

To change the system parameters hold the SET key down for 5

seconds and the controller will enter the parameter set up mode.

The first parameter AH (Alarm High Limit) will show on the display.

Use the Up or Down keys to modify the parameter value then press

the SET key to confirm the change. The display will show the

parameter again. Press the SET key again to show the next

parameter. The instrument will automatically exit if no key is

pressed for 10 seconds. Please see Table 1 for the default

parameters.

Table 1. Parameter Description

Note 1. For cooling (or heating) the receptacle will be off when the

temperature is below (or over) the set point and will be on again

when the temperature rises up (or drops down) to CSP+CdF (or HSP-

HdF). This ensures that the ETC does not try to cool and heat at the

same time.

The maximum value of the HSP can be set is the current value of

CSP. But CSP can be set to the value between 28~221 ºF or

-2~105 ºC. When the CSP is set to a value lower than current HSP

the HSP will be adjusted to the CSP value automatically. This means

that during mashing and boiling it is convenient to set the cooling

set point above 212F so that the heating set point can be set

anywhere below 212F.

For example when CSP=67.0 ºF HSP=62 ºF HSP can be set to any

value between 28 and 67.0. For CSP it can be set to any value

between 28 and 221. If you set it to 55.0 the HSP will be set to 55.0

automatically.

Code Description Setting Range Initial Note

CSP

Cooling Set Point (temp at

which cooling receptacle is

powered)

-2 to 105 C

28 to 221 F

19.4 C

67 F

1

HSP

Heating Set Point (temp at

which heating receptacle is

powered)

-2 to CSP C

28 to CSP F

16.6 C

62 F

AH Alarm High Limit (high temp

at which alarm sounds)

-2 to 105 C

28 to 221 F

35 C

95 F

2

AL Alarm Low Limit (low temp at

which alarm sounds)

-2 to AH C

28 to AH F

0 C

32 F

CdF Cooling Differential (from set

temp to turn cooling on)

0 to 27 C

0 to 50 F 3

1

HdF Heating Differential (from set

temp to turn heating on)

0 to 27 C

0 to 50 F 1

AS

Cooling Antishort (time delay

between turning power

on/off)

0-12 min 0 3

SFA

Sensor Failure Operation (if

sensor fails, which

receptacles are powered)

0-0, 0-1, 1-0 0-0 4

oFS

Temperature Offset

(permanently adjust display

temp)

0-10 0 5

C-F Temperature Units C is Celsius

F is Fahrenheit F

A small differential between heating (HdF) and cooling (CdF) set

points gives tighter control but a larger differential reduces the

frequency of cycling on and off and therefore extends the life of the

relay and compressor.

Note 2. When the measured temperature is higher than the AL set

point the high limit alarm will be on; when the measured

temperature is lower than AL the low limit alarm will be on.

When the alarm is on the display will be flashing between the

measured value and the alarm type. To mute the alarm when it is

on press the Down key momentarily. (If the measured value moves

out of the alarm zone and then returns into the alarm zone again

the alarm will sound again. To disable the alarm set AH=AL.)

The maximum upper value that AL can be set to is the current

value of AH. But AH can be set to any value between 28~221 ºF or

-2~105 ºC. When AH is set to a value lower than the current AL the

AL will be adjusted to the AH value automatically. For example

when AH=95.0 ºF AL can be set to any value between 28 and 95.0.

For AH it can be set to any value between 28 and 221. If you set it

to 55.0 the AL will be lowered to 55.0 automatically as AL cannot

be above AH.

Note 3. The Cooling Antishort is the minimum delay time in

minutes for turning the cooling load back on. When the controller

is used for cooling and the load is a compressor (such as glycol

chiller) it should not turn on the compressor when it is at highest

pressure (e.g. just after it turned off) otherwise it may shorten the

life of the compressor. The Anti-Short cycle delay function

therefore can be used to prevent the rapid cycling of the

compressor. (Technical note: it does this by establishing the

minimum time that the NO contacts remain open—after reaching

cutout—before closing again. The delay overrides any Load

Demand and does not allow the NO contacts to close until the set

time-delay value has elapsed. This allows time for the refrigerant to

be released through the evaporator lowering pressure. It is

typically set to 4-6 minutes).

Note 4. The Sensor Failure defines how the output would be if the

sensor fails. It is a safety feature. It can be set to 0-0 0-1 or 1-0. For

brewing the best option is generally 0-0 as this will shut off any

heater that is connected. Please refer to table 2 for details.

Table 2. Output of the controller when the sensor fails:

Note 5.The Temperature Offset is used to set an input offset to

compensate for any error produced by the sensor or input signal

itself. This is useful for calibrating your ETC for precise readings.

For example for temperature if the unit displays 37 ºF when the

actual temperature is 32 ºF setting parameter to F= -5 will make

the controller display 32 ºF.

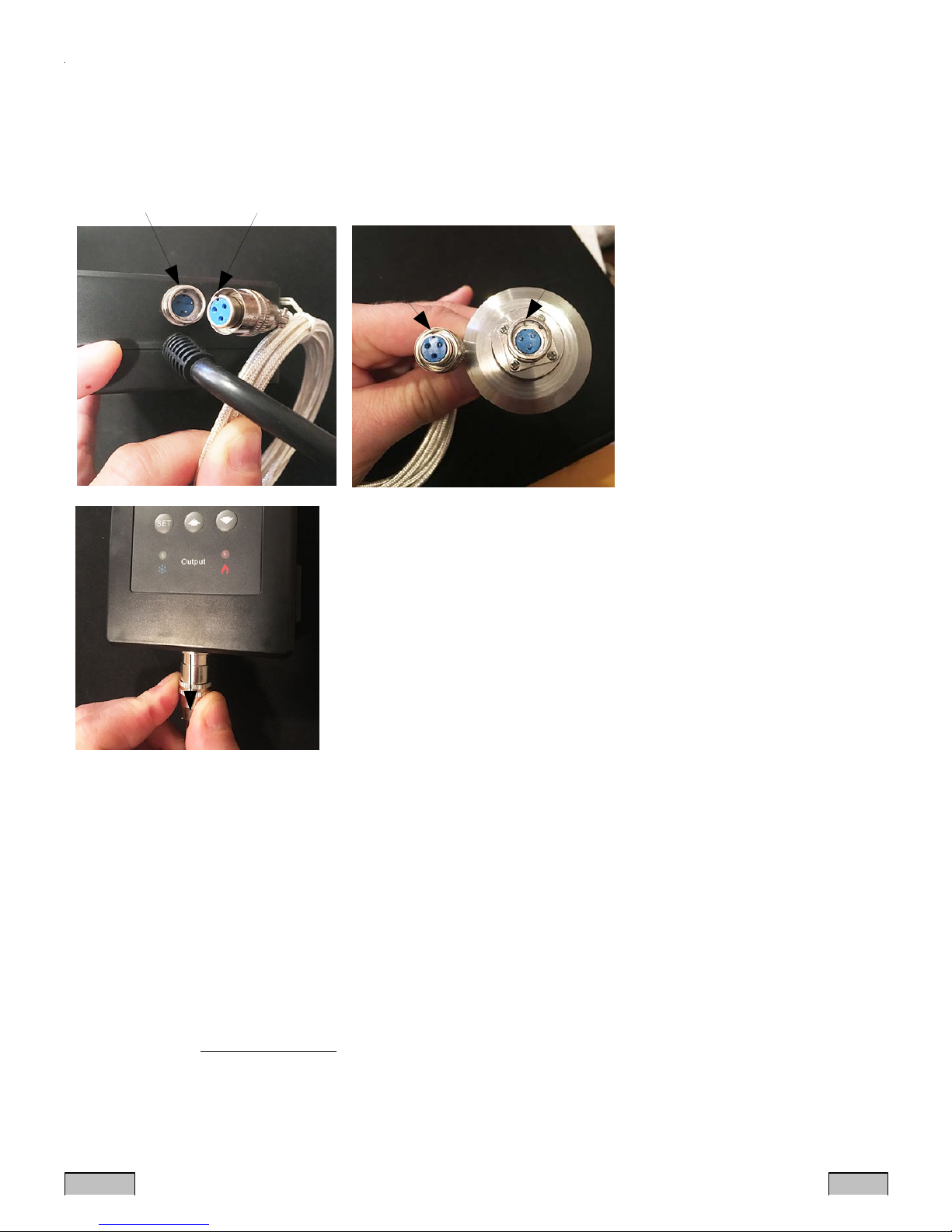

. How to attach the sensor to the unit.

The sensor connector contains a slot for correct pin connection. It

also has a spring lock to prevent disconnections from accidental

pulling on the cable. To attach it to the unit align the slot of the

SFA Controller output when sensor fails

0-0 Cooler and heater off

1-0 Cooler on and heater off

0-1 Cooler off and heater on

BREWHA Equipment Co Ltd. www.brewhaequipment.com

2017.01 P3/3

Questions related to the use of this controller with BREWHA equipment

should be directed to:

BREWHA Eq ipment Co Ltd.

625 Frances Ave

Victoria, BC V8Z1A2

www.brewhaequipment.com

e-mail: [email protected] Tel: 1-844-309-5080

Figure 4. Pull the spring loaded collar to remove the sensor cable.

Figure 3. Ridge on ETC and notch on sensor cable must be aligned when connecting. Same is true for the sensor cable and sensor.

female connector on the temperature probe to the red mark of the

male connector on the ETC unit, then hold the tail and push the

female connector forward. To remove the connector, pull the spring

loaded collar of the female connector back and the female connector

will detach. Please see the Figure 3 and Figure 4 below for details.