BrewSculptures MoreBeer User manual

BrewSculptures

Instruction Manual for the MoreBeer!

Customer Name:____________________

Invoice Number:____________________

Prepared on:________________________

Table of Contents

•Introduction&Caution............................pg.1

•AcceptingShipment.................................pg.1

•Unpacking................................................pg.1

•InitialCleaning.....................................pg.1-2

•KettleOverview.......................................pg.2

•Assembly..............................................pg.2-3

•GravitySystem........................................pg.3

•TippyDumpSystem................................pg.4

•FlatSystem...........................................pg.5-6

•SMARTSystem....................................pg.7-8

•DigitalSMART........................................pg.9

•FullDigitalSMART................................pg.9

•DigitalControllers.................................pg.10

•DigitalHotLiquorBurner.....................pg.10

•TipsOnUsingtheSMARTSystem.......pg.11

•BrewDay..........................................pg.12-15

•CommonQuestions..........................pg.15-16

•Maintenance&Storage....................pg.16-17

•SuggestedItems.....................................pg.17

•WarrantyInformation.......................pg.18-19

Introduction

Thank you for purchasing a MoreBeer!™BrewSculpture™. We here at MoreBeer!™lovingly refer to these

brewing systems as “BrewSculptures™” due to the beauty of their design and their pure ease of use. These systems

are engineered and designed to ensure reliability through symmetry and strength. Their use is intended to be a

pleasurable experience for the brewer as well as those who take part in its rewards - the beer.

Caution

Brewing is hazardous, as it involves open flame, boiling liquids, flammable gas, combustion by-products,

hazardous chemicals, electricity, water, and other possible unforeseen risks. Attempting to brew without sufficient

caution, appropriate safety gear, and attention to hazards can cause permanent injury, including, but not limited

to, scrapes, cuts, burns, scalds, electrocution, cardiac arrest, suffocation, sprains, broken bones, or worse. If at any

time you are not absolutely certain you can exercise the necessary caution to brew safely and are willing to accept

the risks inherent in brewing, you should cease brewing immediately.

Accepting Shipment

As tempting as it may be to sign for the pallet and tear into your new BrewSculpture™as soon as it is

delivered, please take the time to give the shipment a thorough examination by removing the shrink wrap around

the system. Ensure that there is no visible damage to the frame, kettles, or any part of the system. By signing for

the shipment, you are agreeing that there is no damage to the BrewSculpture ™. We may not be able to correct any

damage that may be found once the delivery driver has left.

If you do happen to see small damage to any of the kettles or other small parts, tell the driver that you

would like to sign for the shipment as “Damaged In transit”. Then call our Customer Service Team so that they can

start the replacement process for you.

If you happen to see a dent in the frame of the BrewSculpture™, please call us immediately while the

driver is still there, and ask for Darren, our Metal Shop Manager and Head of BrewSculpture™Construction. If it

is after store hours, or if Darren is unavailable, please tell the driver that you would like to sign for the shipment as

damaged. At this point it is ok to sign for the pallet, as the freight company will now have a record that the unit

arrived in less-than-perfect condition, and we can work with them (and you) to get things fixed.

Please do not refuse shipment if you see signs of minor damage. Most things can be fixed on our end,

and a shipment refusal will complicate matters when it comes to addressing the problem and getting your

system back to you.

Unpacking

Remove all shrink wrap, cardboard, and paper from the system and kettles. Along the base of the

BrewSculpture are four “U-Bolts” attached to the pallet, holding it in place during shipping. The nuts that secure

the U-Bolts are 7/16”, so you will need a 7/16” Deep Socket tool for easy removal. Some parts are stored inside the

kettles or bubble wrap, so make sure you thoroughly inspect each one for missing items.

Initial Cleaning

Before your first brew, you need to clean off any manufacturing oils and dirt. First lightly scrub all of the

brewing components with white, stainless steel safe scrub pads and an appropriate detergent. You can use a warm

PBW solution for this initial scrub down, or any commercial de-greasser such as Simple Green. If you have a pump

1

driven system, recirculate warm PBW solution through the pump and hoses.

Clean the outside of the immersion chiller with PBW also, or if equipped with a counter-flow chiller, clean

the inside. Once all of the manufacturing and shipping dirt has been removed, empty all kettles, lines, chillers, and

pumps and rinse thoroughly with clean, fresh water. In between brews, if you store the equipment clean and dry,

you will not need to use any soap later.

Kettle Overview

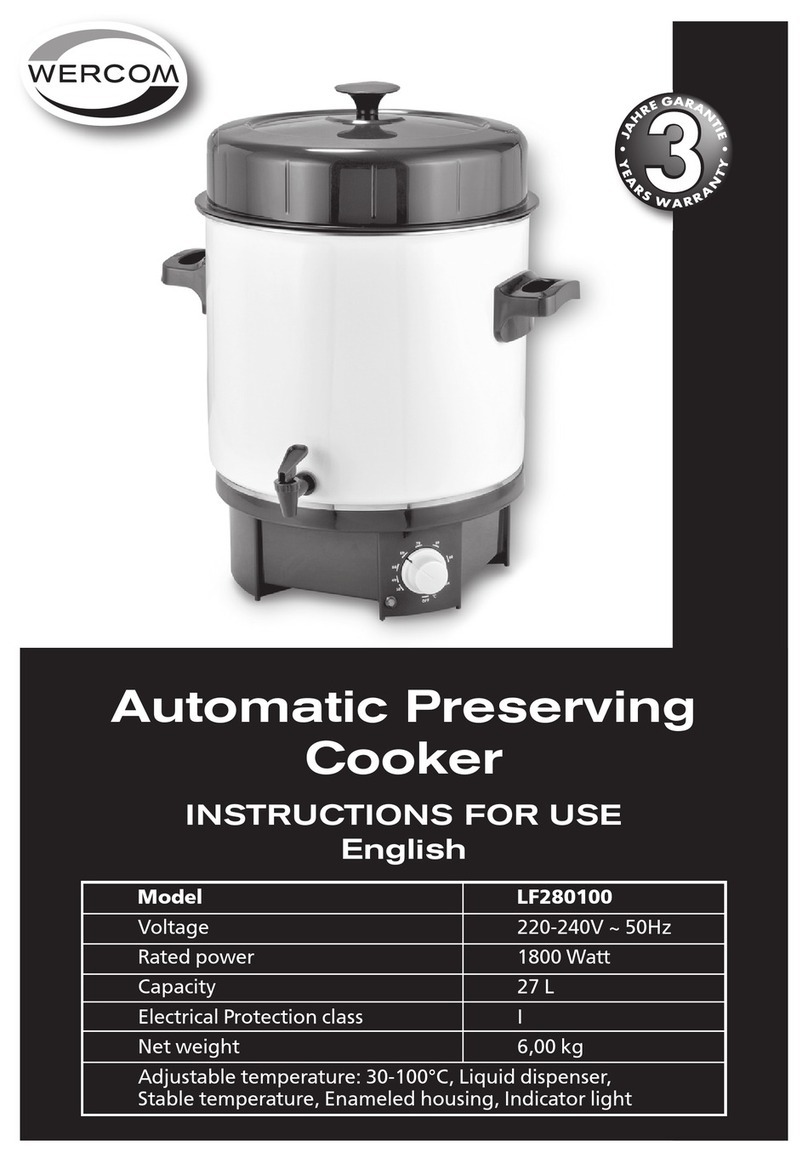

All BrewSculptures™have several basic components in common. This section provides an overview to the

basic components and their functionality.

The Hot Liquor Tank is a vessel that provides hot water for the BrewSculpture™. This hot

water is used for rinsing the sugars from the grains in the mash, for controlling the temperature

of the mash, and sometimes for cleanup after the brew session. A fluid level sight gauge is in-

cluded for measuring the amount of water in the kettle. The sight gauge attaches separately from

the spigot to allow for a more accurate reading even while the fluid flows from the kettle.

The Mash Tun on the BrewSculpture™is used to convert the starches in the grain to sugars.

The grains are kept in the Mash Tun, soaking in hot water until all of the starches are turned

into sugars. Then the water from the Hot Liquor Tank is used to rinse the sugars out into the

Boil Kettle. It has a temperature gauge added for monitoring and recording the exact mash tem-

perature. Within it, there is a raised, perforated false bottom made of 18 gauge, 304 stainless

steel. The perforation is 3/32” holes on 5/32” centers for better recirculation to achieve a clear

run-off right from the start. The false bottom, positioned two inches up from the bottom of the

tun, has a handle for easy installation and removal.

The sweet wort is boiled in the Boil Kettle. This concentrates the sugars, builds melanoidin

flavor compounds, extracts hop flavor and bitterness, and sanitizes the wort.

Assembly

Set the stand in the location where you will be brewing. The ideal location is outside and one that includes:

•Alevelarea

•Freeofammablematerials

•Excellentventilation,toremovecombustiongassesandsteam

•Anearbysourceofelectricity,ifsystemincludesapump

•Anearbysourceofcleanwater

•Anearbydrainforwasteliquids

Make certain all gas valves are closed, and then attach the gas supply to the system regulator. Turn on the

gas supply valve, open the regulator, and check all gas connections with a soapy water solution. If any gas leaks are

evident, try tightening all of the fittings. If need be, remove the fittings and re-apply some Gas Pipe Dope on the

threads and re-assemble the burner system. Once you are certain there are no leaks, carefully turn on gas to one of

the burners and ignite it.

If you have troubles igniting the burner, turn off the gas supply and allow the area to clear of gas for a mini-

mum of 15 minutes until the area is clear. After confirming that a burner works correctly, shut it down and test the

2

remaining burners. After testing each burner in turn, make sure they’re all shut off and then place the boil kettle,

mash tun, and liquor kettle in their respective places. Mount the pump (if so equipped) in the pump holder and

connect the hoses and sensors as needed.

If you have a pump, your system will come with a GFCI Switch, which plugs into the wall. Your pump

should plug into the switch in order to protect you in case water gets onto the ground plug of the pump.

Gravity System

For assembling the Gravity System, place the Hot Liquor Tank (the one with the sight gauge on it) on the

very top shelf. Then the Mash Tun (the one with the false bottom inside) goes in the middle shelf, and the Boil

Kettle sits on the very bottom shelf. Make sure to position the Hot Liquor Tank so that the spigot will be hanging

over the Mash Tun below it, and that the spigot on the Mash Tun is hanging over the boil kettle. The Sparge Ring

threads onto the spigot of the Hot Liquor Tank and hangs into the Mash Tun.

The Sparge Arm is adjustable, for those times when your mash is a little higher or lower than the stock pos-

tions the arm is configured in. A cotter pin at the base of the support arm holds the assembly to the ring, and re-

moval of this pin will allow you to replace the support arm with a longer or shorter one, depending on your needs.

An easy way to calculate your water in your BrewSculpture™kettles is to use this quick calculation to

turn gallons into inches: In our 8 gallon Heavy Duty Kettles, 1 gallon equals 1.5 Inches. In our 15 gallon Heavy

Duty Kettles, 1 gallon equals 0.95 inches. When using this calculation in your Mash Tun, be sure to take your

measurement from the top of the False Bottom.

MashTun

Hot Liquor Tank

Boil Kettle

Gravity Sparge Ring

3

Table of contents