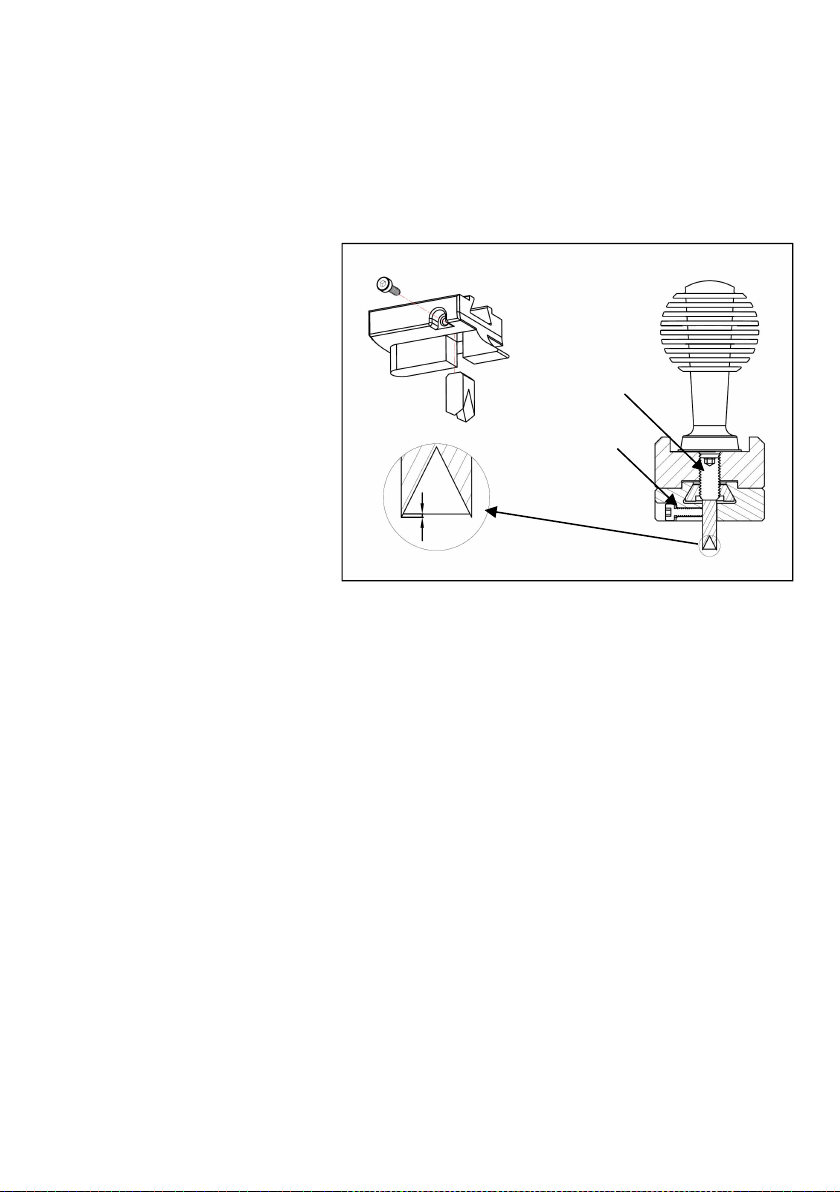

Fine Tuning Screw

Cutting Depth

Set Screw

When the D-shape Scoring Cutter is not needed, loosen, and rotate the cutter to make the small

flat notch parallel to the bottom of the front sole and secure the retaining screw. When in the

retaining position, the cutting edge should not protrude underneath the sole and should have no

impact when cutting. (Refer to Fig. 3 – Retaining Position for reference)

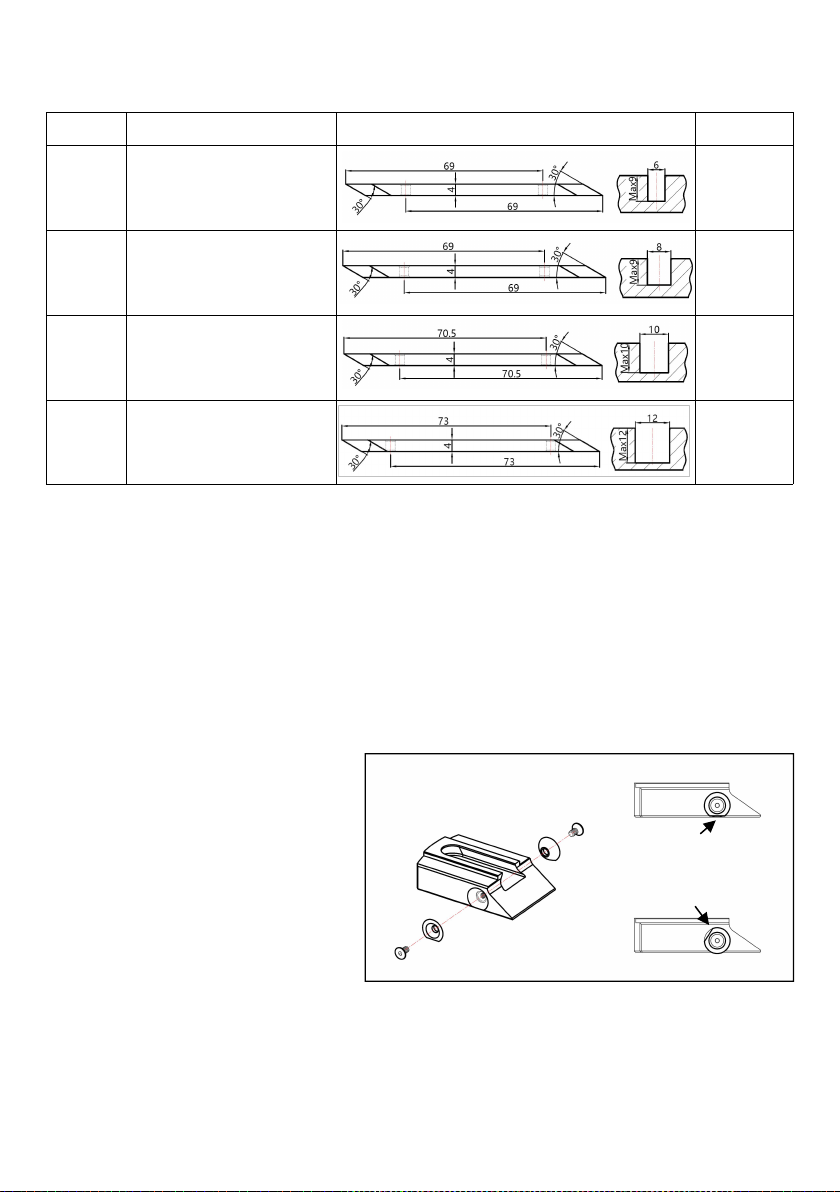

Dado Scoring Cutter (Fig. 4)

The Dado Scoring Cutters is used

with the matching Dado

Groove Irons (2~12mm). The Dado

Scoring Cutter is installed in the slot

of the front sole of the

corresponding iron and tightened

with screws, as shown in Fig. 4.

When adjusting the marking depth,

loosen the screws and move the

Dado Scoring Cutter up and down

to the desired depth. The

fine-tuning screws on the plane

body can be used for additional

After completing all adjustment, tighten the screws to secure the cutter. It is recommended that

the marking depth does not exceed 0.25mm.

Note:The scoring cutter is a special part, if it is worn, you need to replace a new one. To avoid

personal injury, DO NOT ATTEMPT TO HONE OR REPAIR THE SCORING CUTTER. Please reach

out to Bridge City Tool Works customer service to purchase replacement parts.

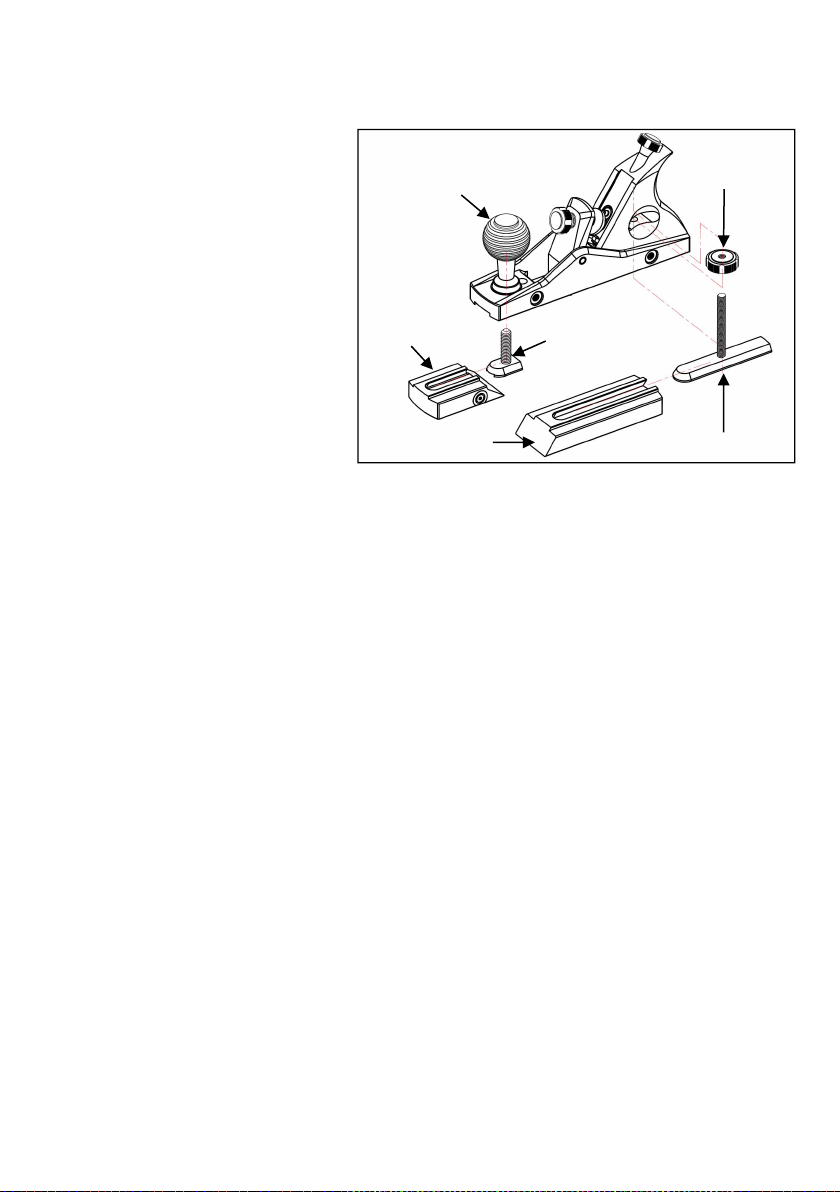

3. The Hone is utilized for the V-Groove Irons and the Crown Irons. It is machined from CNC

aluminum alloy to produce a specific sized V-shape angle and arc. The surface is hardened,

sandblasted, and anodized for an amazing finish. When paired with grinding paste of 6000 mesh

or above, you can achieve a razor-sharp edge on your iron. During the honing process, it is

necessary to ensure that the beveled edge is making complete contact to the honing surface (as

shown in Fig. 5). This is to avoid damaging the iron and hone due to incorrect grinding angle and

direction..

Note: When honing, grinding paste (not included) must be used in conjunction with the hone

to achieve best results.

Fig. 4 Dado Scoring Cutter Installation