Please follow the steps below to remove the iron:

1.Fully open the mouth by loosening the front tote and sliding the

throat plate all the way forward and tighten. This helps to prevent

nicking the iron on the throat plate.

2.Lift the cap until the clamping mechanism is raised to its highest

position.

3.Hold the plane in one hand with your hand on top and your index

finger on the iron. Turn the plane upside down and the iron can be

safely removed as you allow it to drop into your palm.

Please follow the steps below to install the iron:

1.Mount the magnetic iron guard on the end that will not be used.

2.Insert the iron by introducing the protected end first.

3.Slowly lower the iron onto the index pin.

4.Push down the cap to tighten the iron.

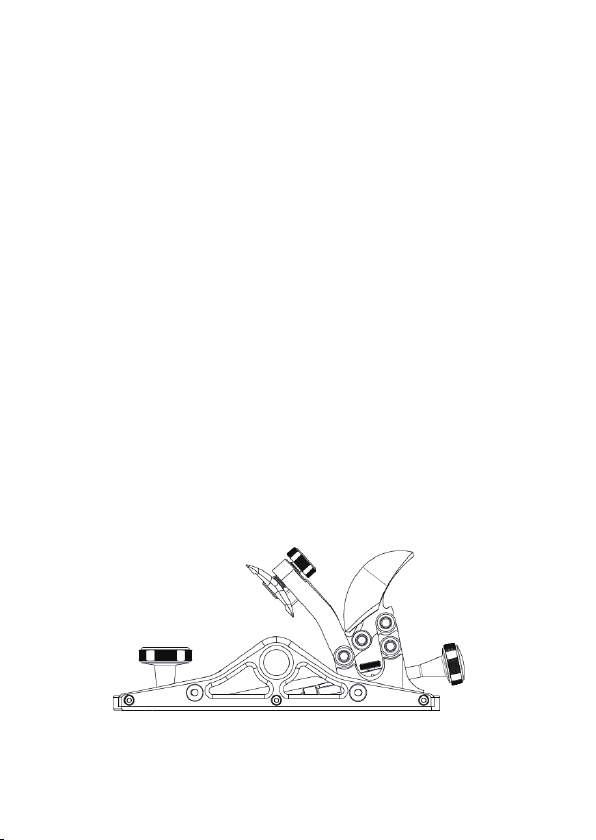

Iron Adjustment

Both cutting depth and cant (iron angle) can be adjusted by the lead

screw under the cap. However, in use we find it much easier to adjust

the cant of the iron with your index fingers through the pockets in the

plane sides.

Adjusting Cutting Depth

The lead screw has 2 threads per millimeter. One full revolution

clockwise will increase the depth of cut by 0.1mm (0.004”). Decrease

the cut depth by rotating the lead screw counter clockwise.

There are five semi-circular cuts milled around the lead screw knob.

These serve two purposes, it is easy to grip and combined with the

knurled sections between each of the five cuts, the lead screw

becomes a base 10 form to achieve incredibly small incremental

adjustments.