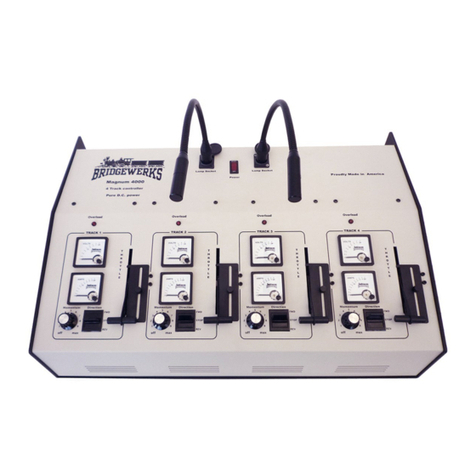

Magnum MS Dual

• Connections:

On the rear of the Magnum MS Dual there are two pairs of connectors la-

belled ‘TO TRACK’ which you use to connect the Magnum MS Dual to your

tracks. If your train is on the track facing forward and you connect the red

terminal to the right rail and the black terminal to the left rail, the train will

go forward when the forward/reverse switch is in the forward position. If

the engine moves backwards, swap the track wires. The best way to con-

nect the Magnum MS Dual to the track is with the included banana plugs.

You can attach your wire to the banana plug, and then just plug it into the

back of the unit.

• Speed Governor:

Bridgewerks’ exclusive “speed-stop” can be used as a safety device to limit

the maximum speed of your trains. There is a speed-stop for each track

which consists of a metal plate held in place with a thumb screw. To adjust

the speed stop, loosen the thumb screw, adjust the throttle slide control so

that the train is going as fast as you want to allow, and then slide the speed

stop down to limit the maximum speed. Tighten the thumb screw. Now you

can move the throttle control from 0 up to the maximum selected speed.

• Momentum:

The SR series feature an adjustable momentum control for each track

which will limit the acceleration and deceleration of the trains. When mo-

mentum is at maximum and you move the throttle from the minimum to the

maximum, the train will slowly accelerate from a stop to the maximum

speed. Similarly if the throttle is moved quickly from maximum to 0, the

train will slowly decelerate to a stop. Momentum adds another dimension

of realism to your model railroad. In addition, the combination of speed

governor and momentum makes it easier to limit derailments when younger

engineers are at the controls.

• Wire:

Use heavy gauge wire to connect your power controller to the track.

For distances of up to 15 feet, you should use 12 gauge wire. For dis-

tances over 15 ft, you use 10 gauge wire. Although the track itself is

similar to a very heavy gauge wire, in larger layouts, significant loss can

occur from the connections between sections of track. To improve this,

run multiple power connections to the track from the controller and/or

use track clamps rather than slider type couplers. In outdoor layouts

which are exposed to extreme temperatures, the track will expand and

contract as the temperature changes, and slider type couplers may

have to be used.

• Outdoor operation

Garden railways are often installed outdoors and Bridgewerks controllers

are built to be used with outdoor railroad layouts. However, they are not

waterproof, and as with any electronic equipment, they should not be left

outdoors when not in use. To make this easy, the connections are all

made so that they can simply be unplugged and the controller can be car-

ried indoors.

• Overload Protection:

In the event of an overload, the Magnum MS Dual has two different ways of

protecting itself and your train from damage. A manual circuit breaker is on

the left side of the rear panel. The button will pop out and the power to the

track will be cut off. If this happens, correct whatever caused the overload,

wait 2 or 3 minutes and then push the switch to reset it.

In addition, there is an automatic thermal cutoff inside the controller, which

will be activated in the event of an overload. This will reset itself automati-

cally in 2-3 minutes after the cause of the overload is removed.

• Direction Control:

The Magnum MS Dual has a direction control switch for each track which

will change the direction of the locomotive. When the switch is changed,

the color of the light above the switch will change color. If the locomotive

runs backwards when the switch is in the forward position, reverse the con-

nections going to the track.