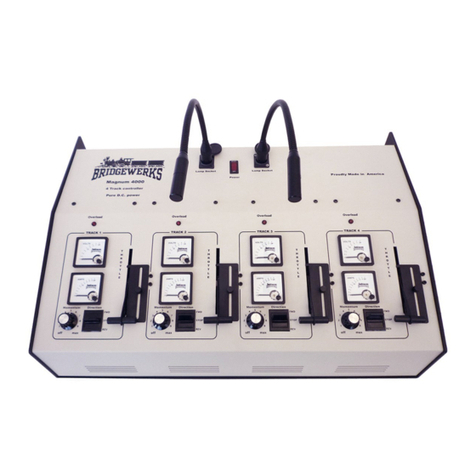

Magnum 20-SRS Features

• Connecons:

On the rear of the Magnum SRS there is a pair of connectors labelled ‘TO TRACK’ which you use to con-

nect the Magnum 20-SRS to your track. If your train is on the track facing forward, and you connect the

red terminal to the right rail, and the black terminal to the le rail, the train will go forward when the

forward/reverse switch is in the forward posion. If the engine moves backwards, swap the track wires.

The best way to connect the Magnum 20-SRS to the track is with the included banana plug. You can

aach your wire to the banana plug, and then just plug it into the back of the unit.

In addion to the TRACK connecon, there is a connecon which provides full voltage (24-32VDC) output

which can be used to power accessories such as lighng or switch motors. You can connect to these

terminals with a banana plug (addional plugs are available from Bridgewerks or from a local audio

shop), or by unscrewing the connecon a lile, and then ghtening down on the bare wire.

The yellow connectors are for use by the RC-100 remote control (not included.)

• Speed Governor:

Bridgewerks’ exclusive “speed-stop” can be used as a safety device to limit the maximum speed of your

trains. The speed stop consists of a metal plate which is held in place with a thumb screw. To adjust the

speed stop, loosen the thumb screw, adjust the throle slide control so that the train is going as fast as

you want to allow, and then slide the speed stop down to limit the maximum speed. Tighten the thumb

screw. Now you can move the throle control from 0 up to the maximum selected speed.

• Momentum:

The momentum switch on the front panel will limit the acceleraon and deceleraon of the trains. When

momentum is enabled and you move the throle from the minimum to the maximum, the train will

slowly accelerate from a stop to the maximum speed. Similarly if the throle is moved quickly from

maximum to 0, the train will slowly decelerate to a stop. Momentum adds another dimension of realism

to your model railroad. In addion, the combinaon of speed governor and momentum makes it easier

to limit derailments when younger engineers are at the controls.

• Direcon Control:

The Magnum 20SRS has a direcon control switch which will change the direcon of the locomove. If

the locomove runs backwards when the switch is in the forward posion, reverse the connecons going

to the track.

• Overload Protecon:

In the event of an overload, the Magnum 20SRS has two dierent ways of protecng itself from damage:

A manual circuit breaker on the le side of the rear panel. The buon will pop out and the power to the

track will be cut o. If this happens, correct whatever caused the overload, wait 2 or 3 minutes and then

push the switch to reset it.

In addion, there is an automac thermal cuto inside the controller, which will be acvated in the event

of an overload. This will reset itself automacally in 2-3 minutes aer the cause of the overload is re-

moved.

• Oponal Remote Throle Capability (RC-100):

On the back of the 20-SRS, there is a pair of yellow terminals for the remote control—plug the receiver

into these two yellow terminals (it will automacally also plug into the accessory power pins), and pro-

vide you with wireless remote control over the throle

• Speedometer:

The 20SRS has the ability to show the scale speed of the locomove once it has

been properly calibrated. To calibrate:

1. measure out a scale distance on your layout according to ‘table A’

2. Turn the ‘MPH’ knob to 5 and the “O” adjust knob to “A”

3. With your train on the track, slowly increase the speed (using the slide throle)

unl the train begins to move, then turn the “0” adjust knob unl the speedometer

just starts to move.

4. Increase the throle so that the train is moving at a medium speed. Time the

amount of me that it takes for the train to move through the distance that you

measured out in step 1. Using table B, determine the speed of your train in Scale

MPH.

5. Connue running at medium speed. Using the scale MPH speed that you calculated

in step 4, adjust the MPH knob to show that speed. For example, if your train took

12 seconds to cover the pre-measured distance, then it is going 30MPH. So you

adjust the MPH knob to get the speedometer to read 30MPH.

• Wire:

Use heavy gauge wire to connect the 20-SRS to the track. For distances of up to 15 feet, you should

use 12 gauge wire. For distances over 15 , you use 10 gauge wire. Although the track itself is

similar to a very heavy gauge wire, in larger layouts, signicant loss can occur from the connecons

between secons of track. To improve this, run mulple power connecons to the track from the

controller and/or use track clamps rather than slider type couplers. In outdoor layouts which are

exposed to extreme temperatures, the track will expand and contract as the temperature changes,

and slider type couplers may have to be used.

• Outdoor operaon

Garden railways are oen installed outdoors and Bridgewerks controllers are built to be used with

outdoor railroad layouts. However, they are not waterproof, and as with any electronic equipment,

they should not be le outdoors when not in use. To make this easy, the connecons are all made so

that they can simply be unplugged and the controller can be carried indoors.

MPH Sec

10 36

15 24

20 18

25 14.5

30 12

35 10

40 9

45 8

50 7

55 6.5

60 6

65 5.5

70 5

75 4.8

80 4.5

85 4.2

90 4

95 3.8

100 3.6

105 3.4

110 3.3

115 3.1

120 3

Table B

Scale F

1:20.3

G

1:22.5

G

1:24

#1

1:32

O

1:48

S

1:64

HO

1:87.1

Distance 26 23.5 22 16.5 11 8, 3ins 6

Table A