1. Product Description.................................................................................................................2

1.1. Gas type .........................................................................................................................2

1.2. CE approval ...................................................................................................................2

1.3. Firepits UK Ltd..............................................................................................................2

1.4. Serial number location ...................................................................................................2

2. Getting started .........................................................................................................................3

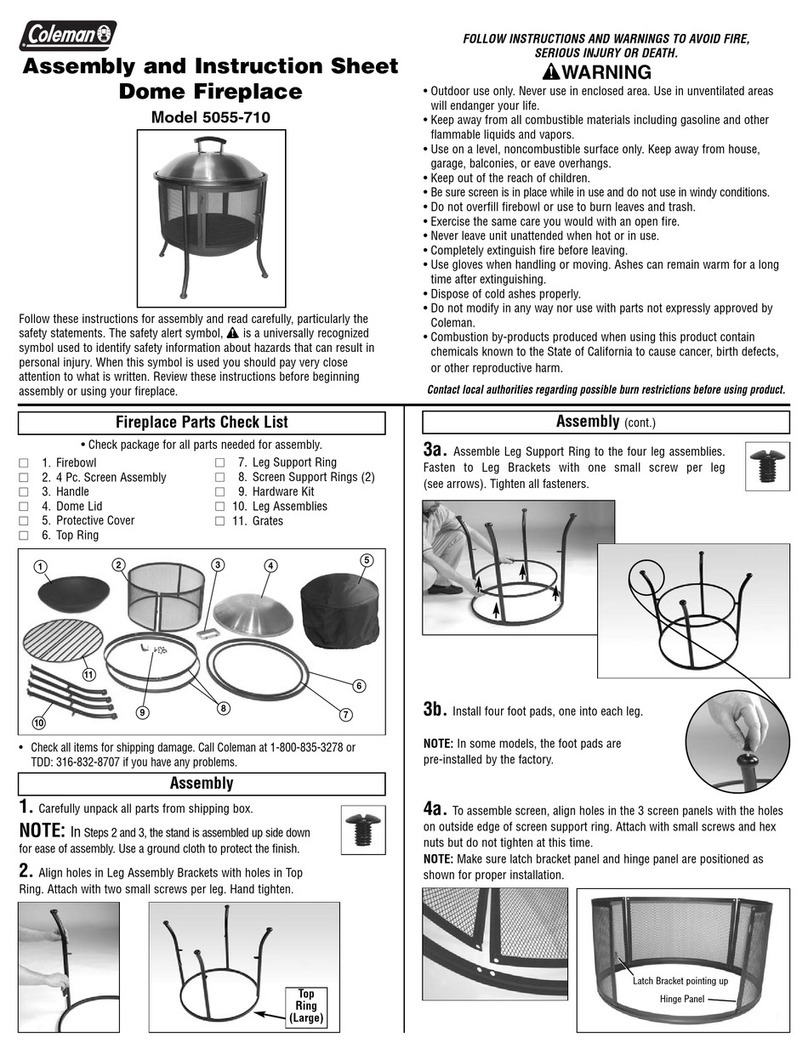

2.1. Unpacking the box .........................................................................................................3

2.2. Specifications.................................................................................................................3

2.3. What's Included..............................................................................................................3

2.4. Assembly........................................................................................................................4

3. Safety.......................................................................................................................................5

3.1. Intended use ...................................................................................................................5

3.2. Basic safety instructions.................................................................................................5

4. Firepit Location .......................................................................................................................6

4.1. Location .........................................................................................................................6

4.2. Weather covers...............................................................................................................6

5. LPG Installation.......................................................................................................................7

5.1. LPG Bottle Types...........................................................................................................7

5.2. Bottle storage .................................................................................................................7

5.3. Regulators ......................................................................................................................8

5.4. LPG Hose.......................................................................................................................8

6. Installation...............................................................................................................................9

6.1. Testing............................................................................................................................9

6.2. Lava Rock....................................................................................................................10

7. Operating Instructions ...........................................................................................................11

8. Troubleshooting - New Installations......................................................................................12

9. Troubleshooting - Existing Installations................................................................................14

10. Servicing and Maintenance ..............................................................................................16

11. Warranty...........................................................................................................................18