25

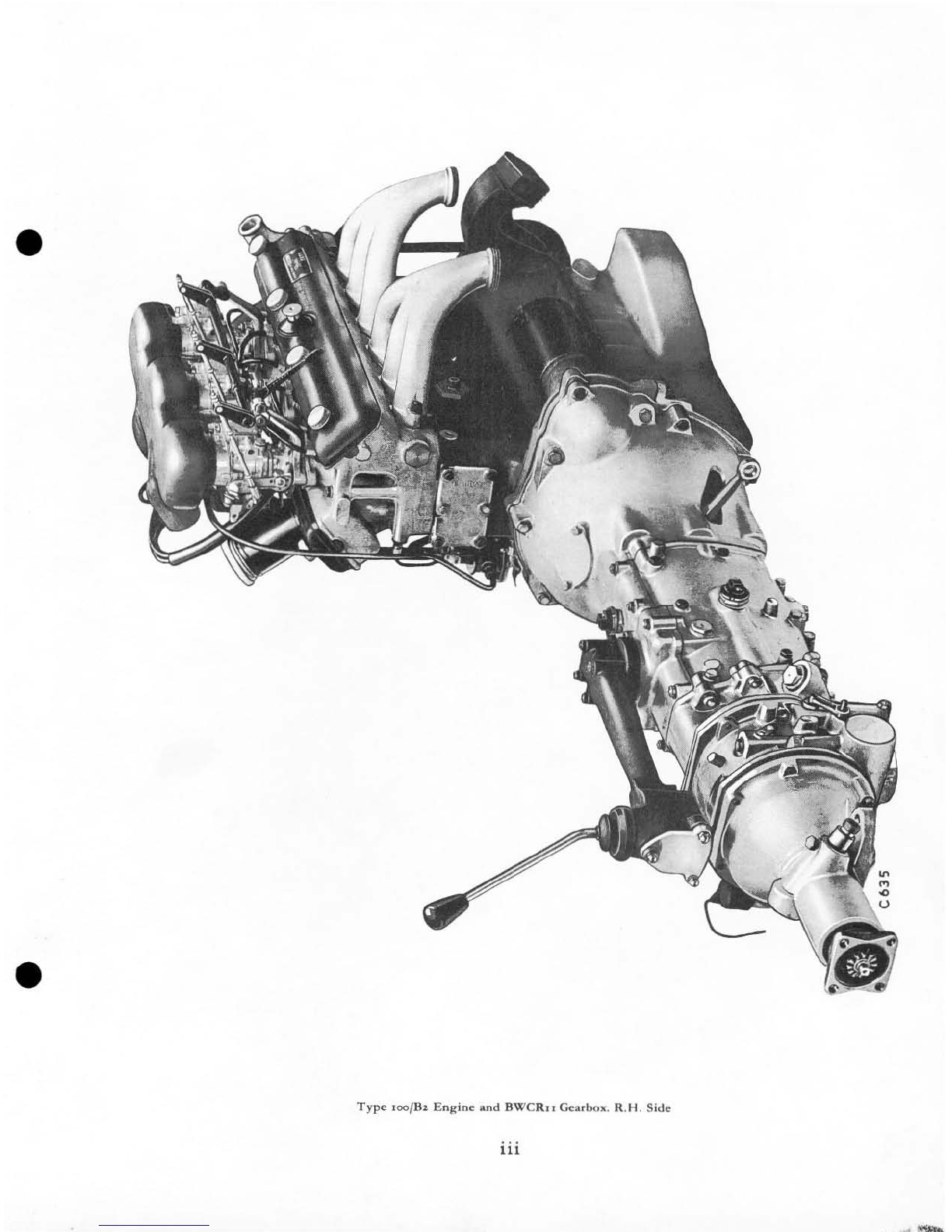

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

2.

" " "

20

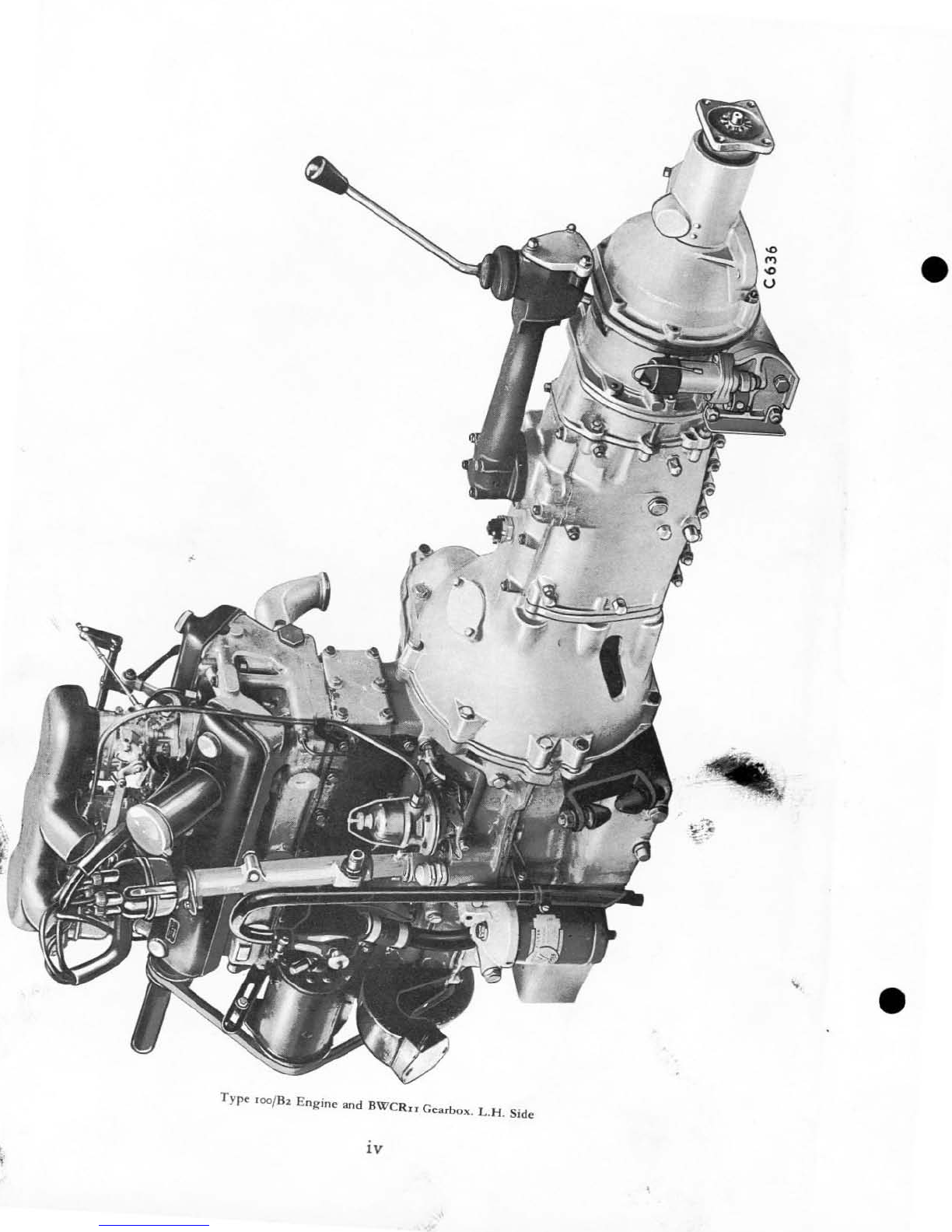

Fan.

Water

pump.

Inlet

rocker

cover

.

AII'

intake

manifold.

H.

T.

leads.

Air

clea

ner.

19

Petrol

feed

pipe

(pump

to

carbs

L

Oil feed pipe

co

rockers

.

Gearbox

remote

co

ntrol.

Rear

mounting.

Speedome

rer

drive

.

Cylinder

drain

coc

k.

Petrol

pump.

"

Key

17

14.

15.

16.

17.

18.

19.

20.

21.

22

.

23.

24.

25

.

26.

"

Torque buffe

rs.

Sump

drain

plug.

Engine

breather

pipe.

10

Oil

thermometer

conn

ec

.tio

n.

Dipstick.

Oil

filter.

Oil

pressure

relief

valve.

Engine

speed

indica~or

drive.

Oil

return

pipe

separator.

Engine

fronc

mounting.

Dynamo.

Vibration

damper.

Gearbox l

evel

plug.

Type 100B

Engine

with BWCR7 Ge:.l,bo,.. L.H.

Side

u

•

•