285 Issue 1 - Service Manual - Iceberg

iv

9.1 Pump Removal..................................................................................................................... 19

9.2 Circulation Pump – Electrical checks ................................................................................... 20

9.2.1 Pump will not operate........................................................................................................ 20

9.2.2 If power present:................................................................................................................ 21

9.2.3 If pump doesn't operate:.................................................................................................... 21

9.2.4 If NO power: ...................................................................................................................... 21

9.2.5 If Pump doesn’t operate: ................................................................................................... 22

9.2.6 Circulation Pump - Mechanical Checks............................................................................. 22

9.3 Drain Pump .......................................................................................................................... 22

10.0 Winter seal damper assembly ............................................................................................ 23

10.1 Dismantling......................................................................................................................... 24

10.2 Damper motor assembly will not open ............................................................................... 26

10.3 If power is present to the switch terminal, but not to the motor terminal:............................ 26

10.4 If power is present at the motor terminal: ........................................................................... 27

10.4.1 If damper motor assembly does not operate: .................................................................. 27

10.4.2 If motor operates: ............................................................................................................ 27

10.4.3 If NO power present at ServoSeal motor Active Open terminal:...................................... 28

10.4.4 If winter seal damper motor operates: ............................................................................. 28

10.4.5 If winter seal damper motor doesn't operate: .................................................................. 28

10.4.6 Damper blade will not close:............................................................................................ 29

10.4.7 Circuit Diagram:............................................................................................................... 29

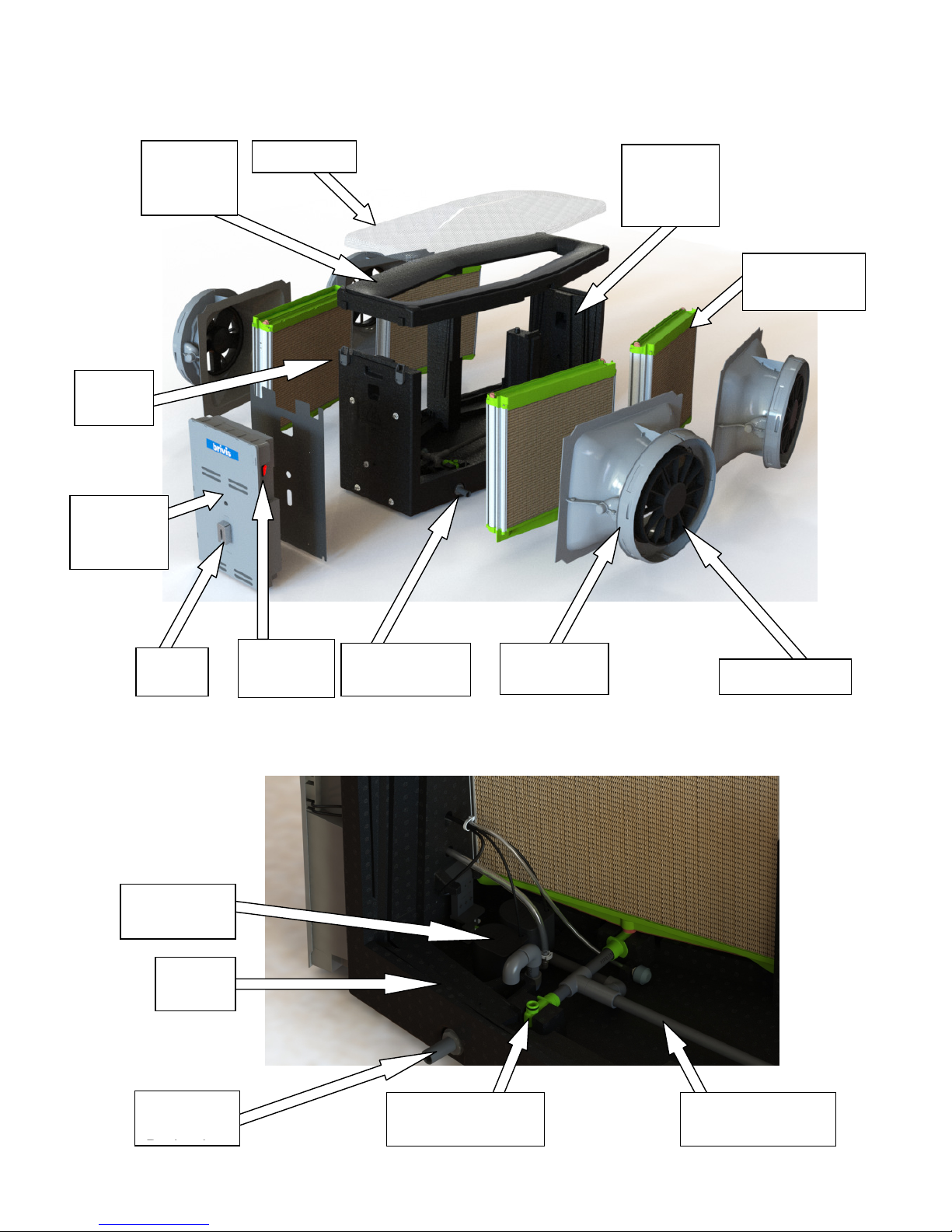

11.0 Fan Motor Assembly .......................................................................................................... 30

11.1 Fan motor assembly removal ............................................................................................. 31

11.2 Fan Motor will not operate.................................................................................................. 32

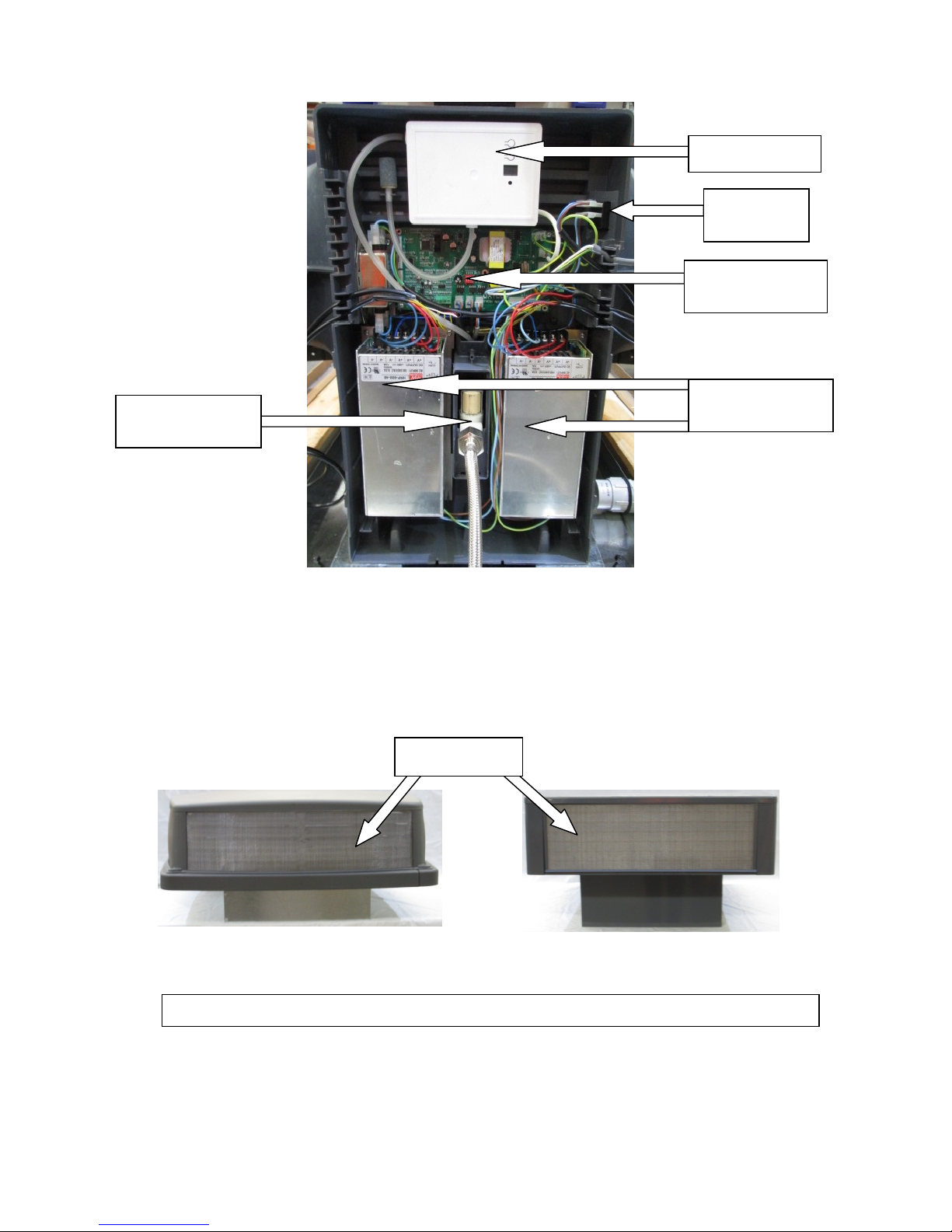

12.0 Brivis Iceberg Wall Control ................................................................................................. 34

13.0 Dip Switches & Potentiometer............................................................................................ 37

13.1 Dip Switch Settings ............................................................................................................ 37

13.2 Potentiometer - Drain refill cycle count............................................................................... 38

14.0 Evaporator Module – Primary Drain ................................................................................... 39

14.1 Safety Tray – Secondary Drain .......................................................................................... 39

15.0 Final Checklist .................................................................................................................... 40

16.0 Iceberg Cooler Service....................................................................................................... 41