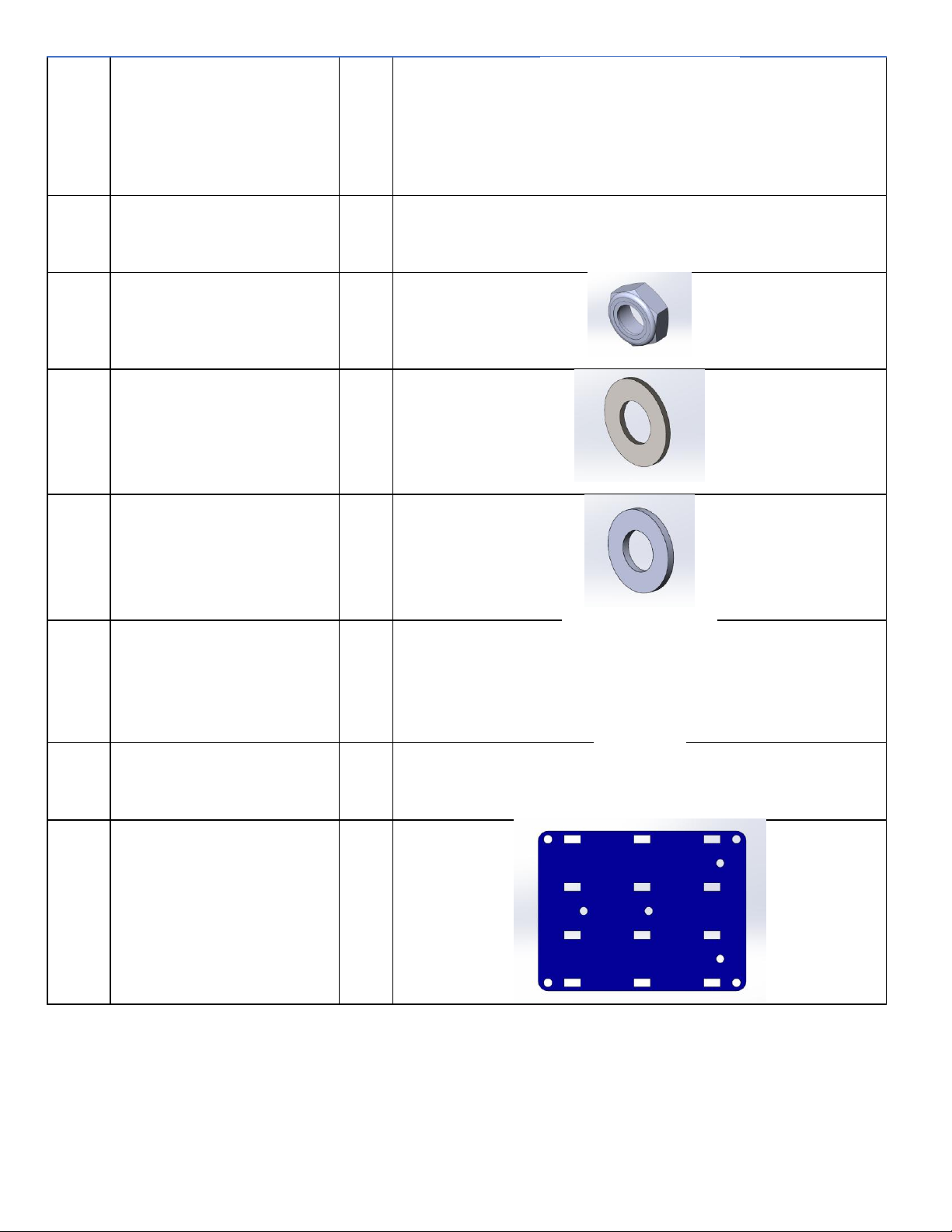

2

Contents

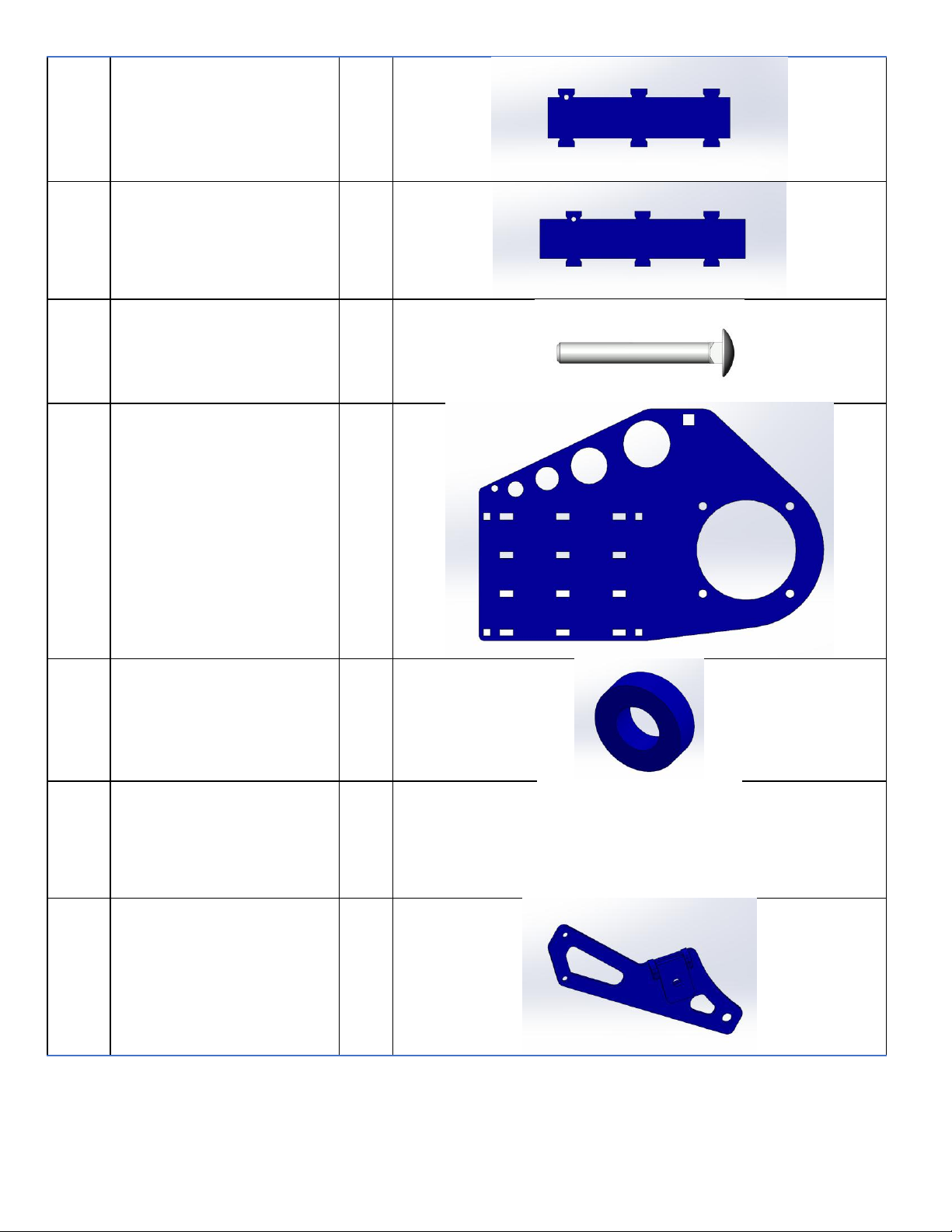

Main Chassis Assembly.......................................................................................................... 9

Step 1 –Hinge and Hinge Base RH ......................................................................................9

Step 2 –X Brace............................................................................................................... 10

Step 3 –Hinge Base LH..................................................................................................... 11

STEP 4 –Hinge Side Plate ................................................................................................. 12

STEP 5 –Tool Arm Plates.................................................................................................. 13

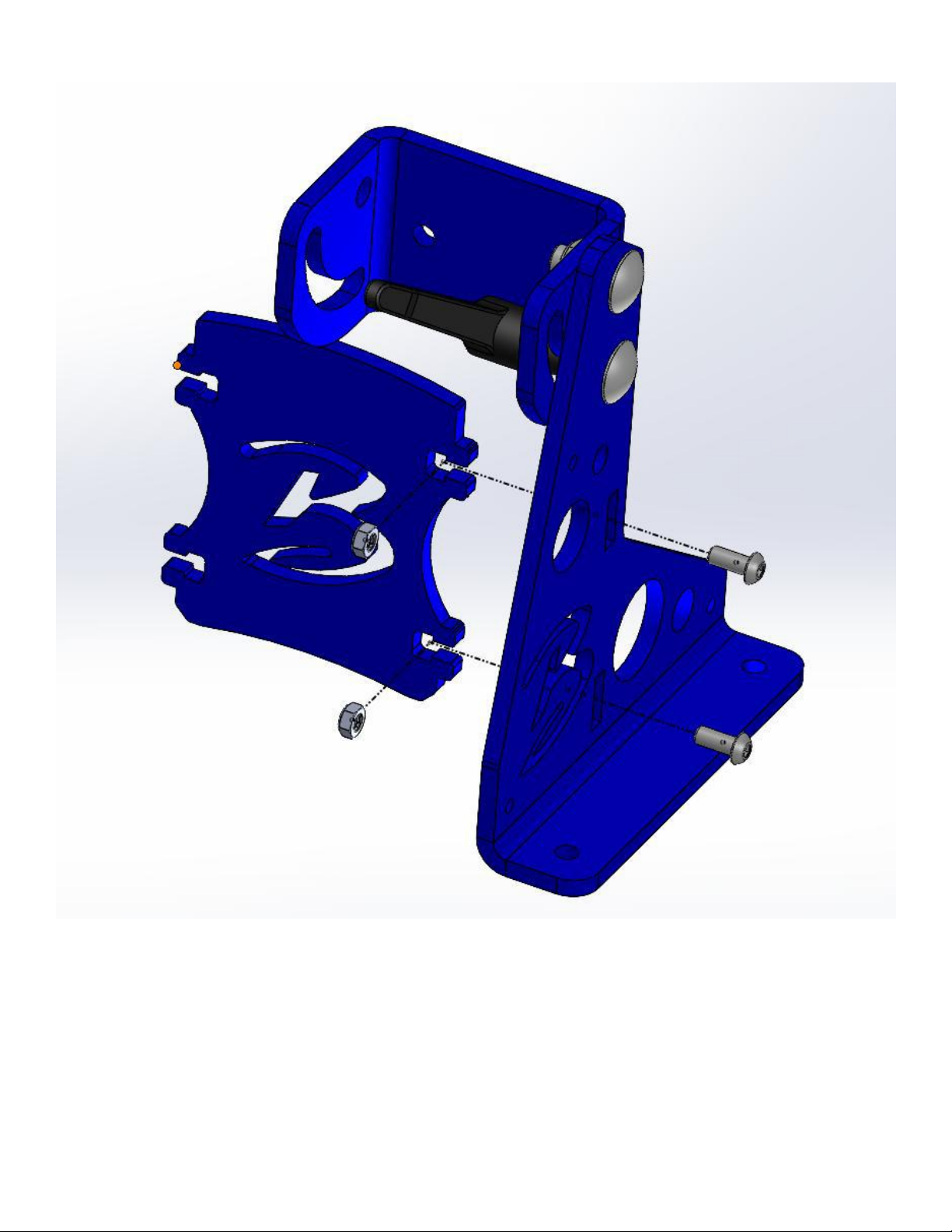

STEP 6 –Motor Mount Side Plate..................................................................................... 14

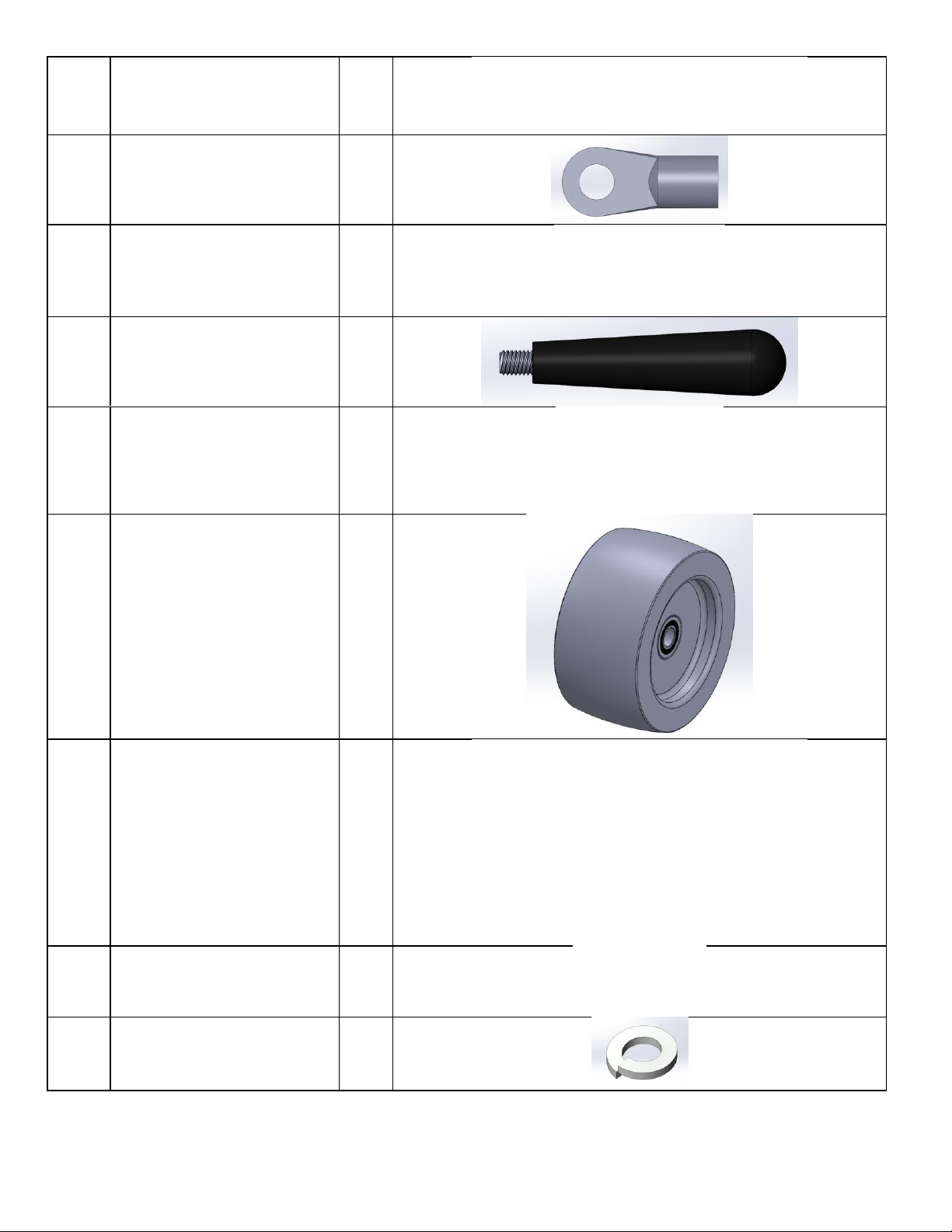

STEP 7 –Tension Arm ......................................................................................................15

STEP 8 –Gas Spring.......................................................................................................... 16

STEP 9 –Tracking Knob and Handle.................................................................................. 17

STEP 10 –Tracking Wheel ................................................................................................ 17

STEP 11 - Motor Install..................................................................................................... 18

STEP 12 - Drive Wheel Install............................................................................................ 19

Wiring Instructions ..............................................................................................................21

Variable Speed Motor Wiring........................................................................................... 21

VFD Setup ....................................................................................................................... 23