1

Contents

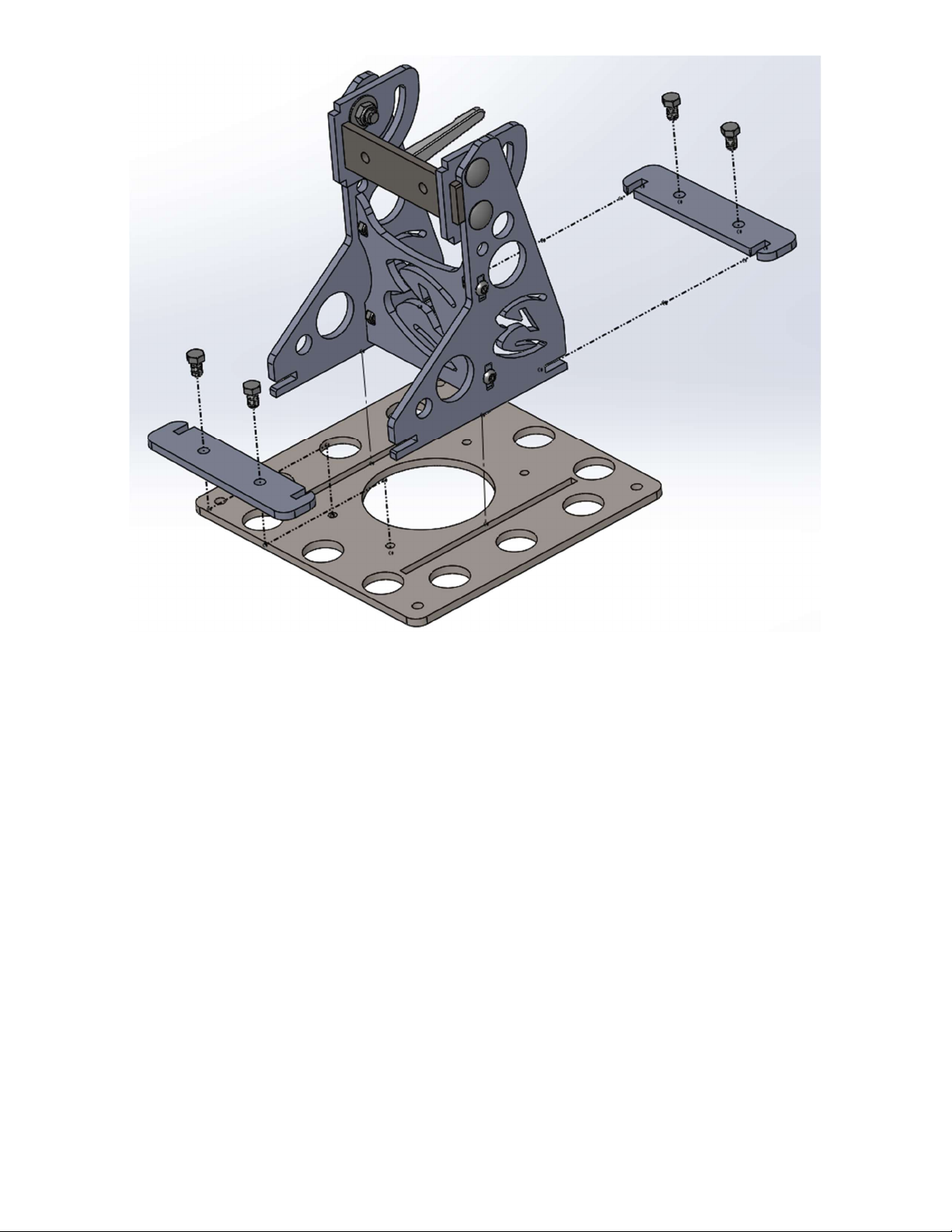

Main Chassis Assembly .............................................................................................................. 2

Tracking and Tension Assembly ................................................................................................. 7

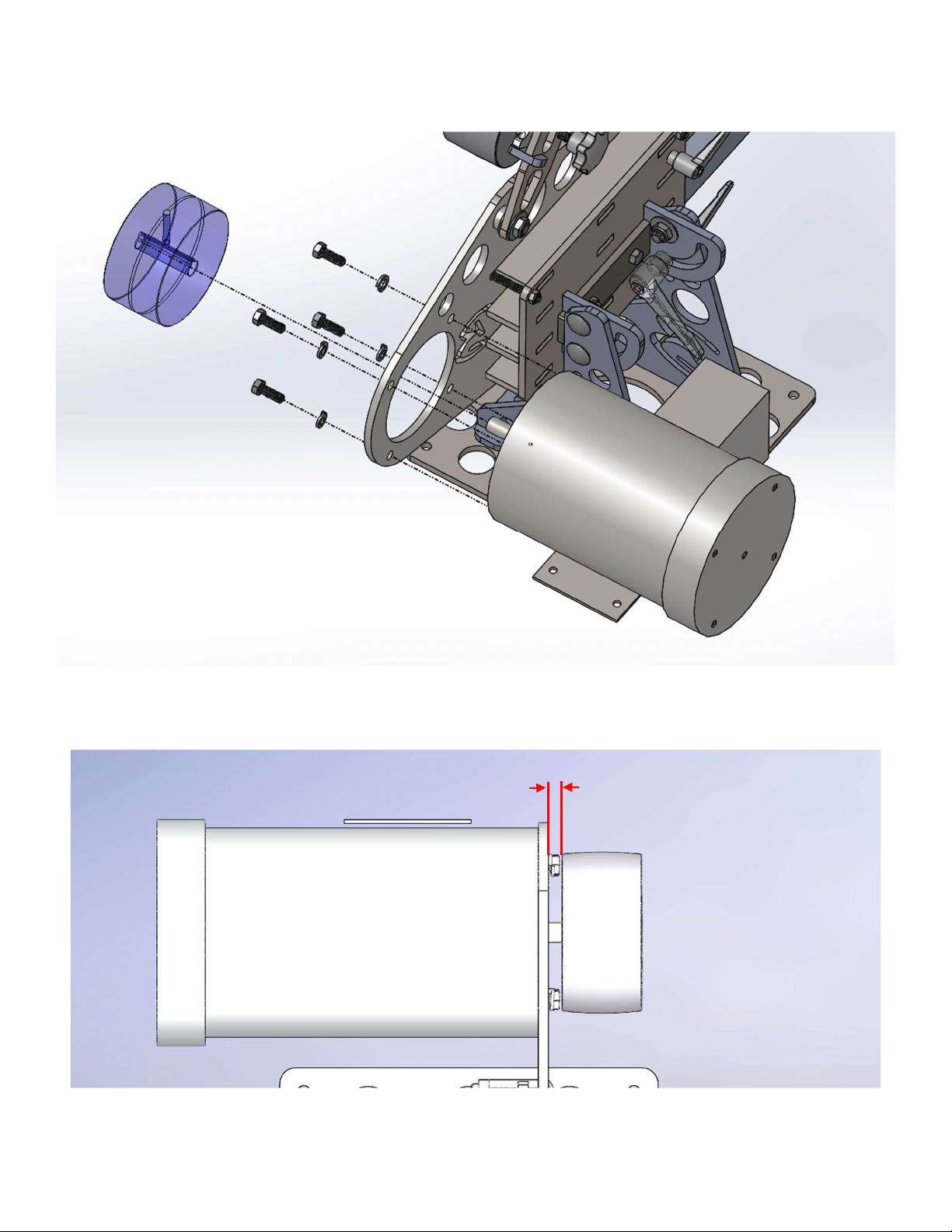

Motor Install .............................................................................................................................. 9

Accessories .............................................................................................................................. 11

Work Rest Assembly ............................................................................................................ 11

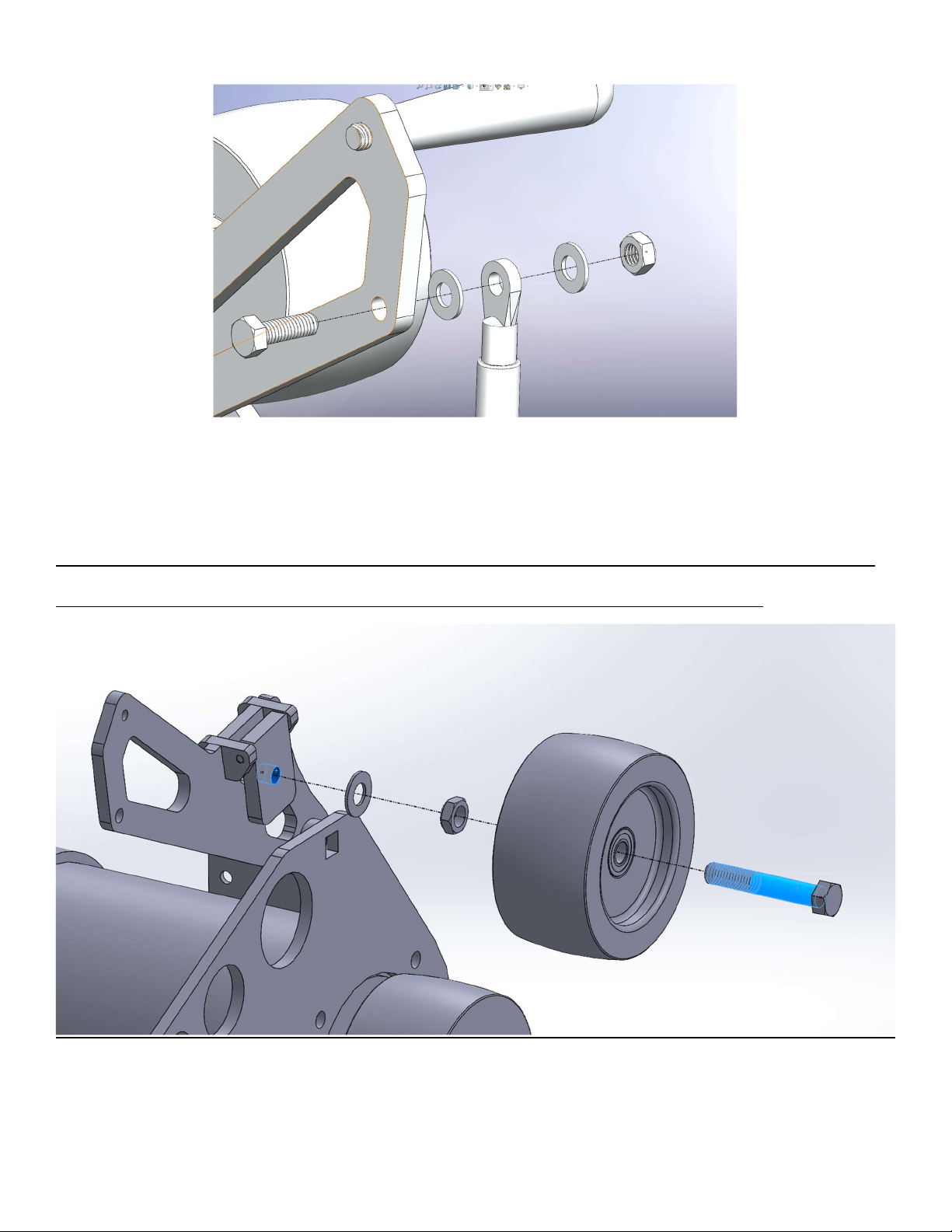

Contact Wheel Assembly ..................................................................................................... 12

MAREKO DEEP PLATEN ASSEMBLY ....................................................................................... 13

10” Platen Assembly ............................................................................................................ 15

Small Wheel Attachment Assembly ..................................................................................... 17

Slack Wheel Attachment Assembly ...................................................................................... 18

QUICK CHANGE ATTACHMENT ASSEMBLY ........................................................................... 19

Integral Bolster attachment assembly .................................................................................. 20

Bearing Sets...................................................................................................................... 20

Integral Attachment ......................................................................................................... 21

Wiring Instructions .................................................................................................................. 22

Variable Speed Motor Wiring ............................................................................................... 22

VFD Setup ............................................................................................................................ 24

WARNING:

THE OPERATION OF THIS MACHINE MAY RESULT IN INJURY, DISMEMBERMENT, OR DEATH.

Lockout and secure power source before performing any work on the machine.

Make sure to use adequate personal protection equipment such as eye protection,

respirator, etc. while operating this equipment.

Contact Brodbeck Ironworks LLC for any questions or concerns before operating this

equipment