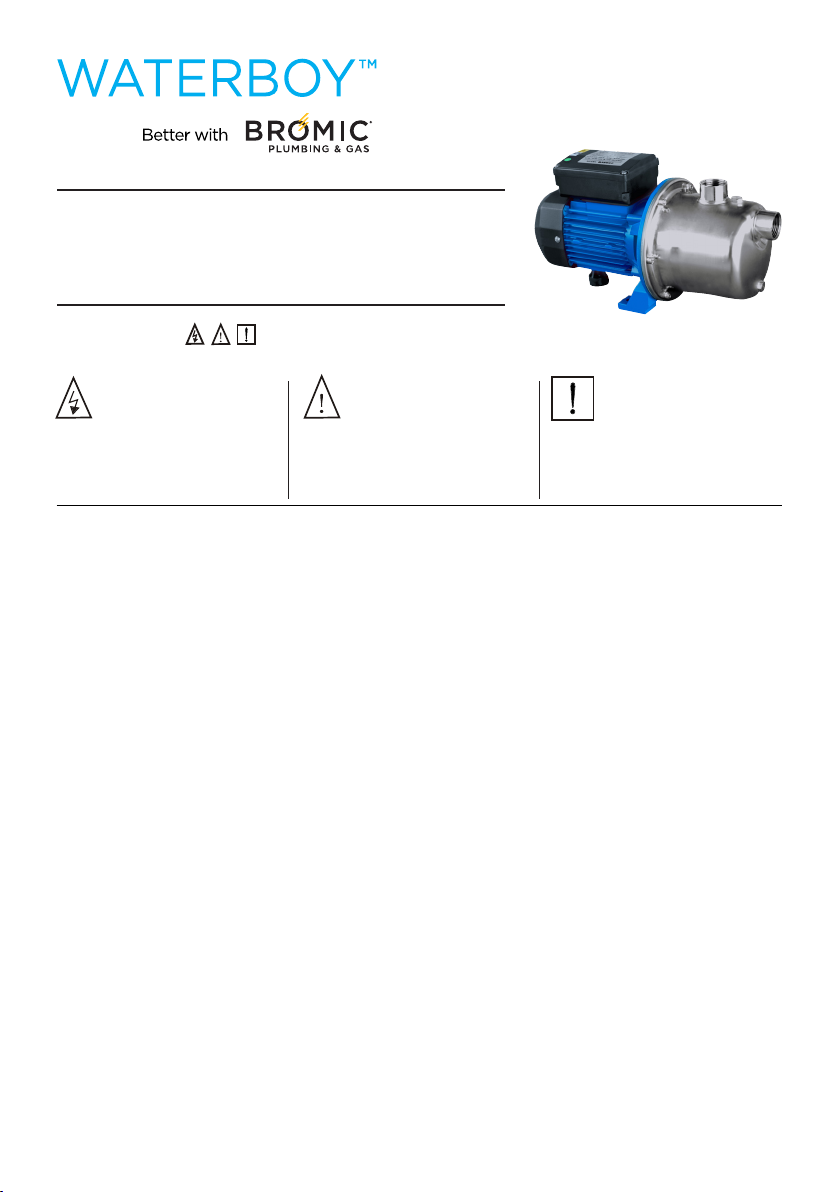

4. ELECTRICAL CONNECTION OVERALL DIMENSION

Electrical installation must only be completed by an authorised and trained technician in

line with Australian safety regulations. The electric installation should be provided by a

system of multiple separations with contact openings of at least 3 mm. The protection

of the system will be made by a dierential switch (1fn=30mA.) The electric cable must

correspond with Australian standards and be sucient for the load generated. The single

phase motors have a built-in thermal protection. Look at the schematic drawing on Fig(1)

for a correct electrical connection. KEEP AWAY FROM CHILDREN.

5. CONTROLS PRIOR TO THE INITIAL STARTING

Check that the voltage and frequency of the electric supply correspond to that indicated

on the technical characteristics label. Make sure that the shaft rotates freely. Fill pump

body with water, unscrewing slightly the priming plug. Verify the motor sense of rotating as

indicated on the fan cover. THIS PUMP SHOULD NEVER BE DRY OPERATED.

6. STARTING

Open all gate valves installed in the suction ( LINE ), connect to the electric supply switch,

wait for the priming to be completed. If a foot valve has been installed, the priming will be

instantaneous. If the motor fails to start, or does not deliver water. Refer to our trouble-

shooting guide with the possible problems and subsequent actions to take.

7. MAINTENANCE

Bromic electro pumps do not require special maintenance. The pump body must be

drained during periods of low temperatures (temperatures below 1°C) or long period of

inactivity. If the pump is inactive for over 60 days, the pump should be cleaned and stored

in a dry and ventilated place.

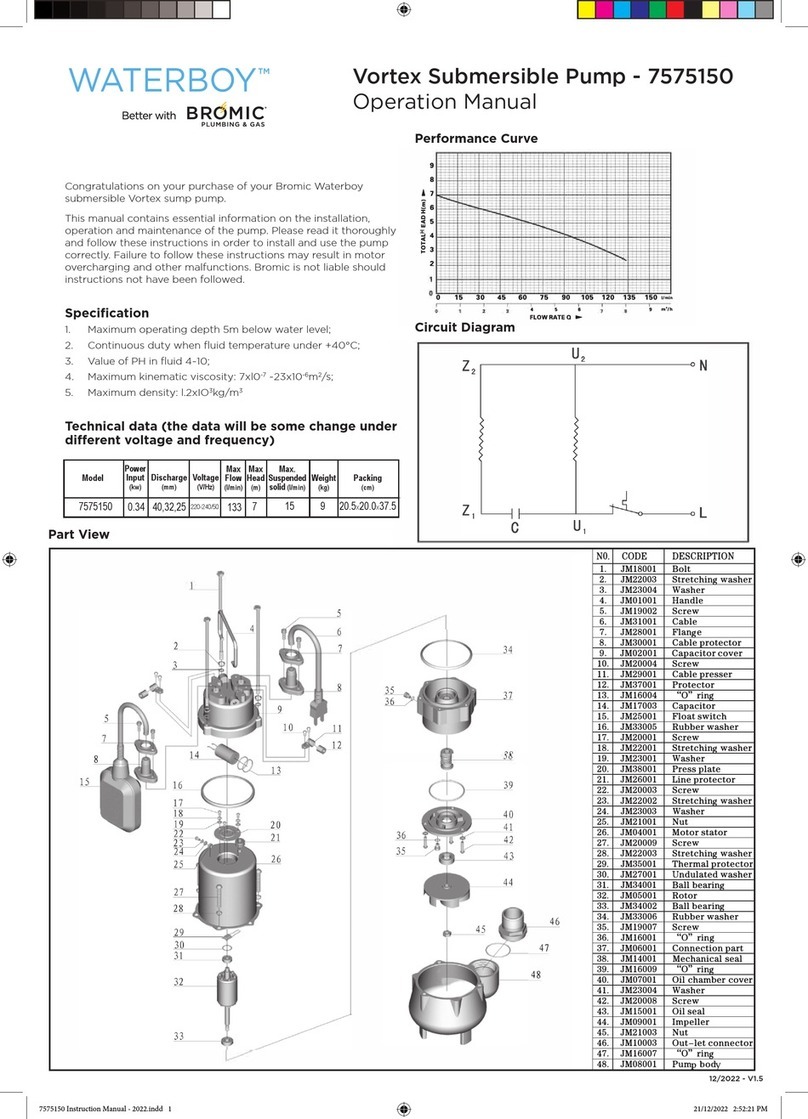

PERFORMANCE CURVE

2AU 1300 276 642 NZ 0508 276 642 | W BROMICPLUMBING.COM | E PLUMBING@BROMIC.COM

MM

L N

Line in Line in

Fig1

Black

Blue

Brown

Z1

Z2

U2U1

U

VW

SYSTEMPROBLEM POSSIBLEPROBLEM SOLUTIONS

The moto r does start.

Motorstartsand

stops continuously.

Disconnectit andtakeit

to the Official

TechnicalService.

Flow is insufficient Foot valve clogged Cleanit orreplaceby newone

Thereis nosuction.

Flow is insufficient

Totalmanometrichead

higherthanexpected.

Verify geometricheadandloss

of head.

The motordoesnot start.

Motorover-heating.

Motorstartsandstops

continuously.

Wrongtension.

Checkthatthetensionis the

same as thaton the technical

characteristicslabel.

Thereis nosuction.

Motorrunsbutit gives

no pression.

Flow is insufficient.

Waterlevel in well or

tankhas comedown. Verify suctionhead.

The motordoesnot start. Fuse or thermalrelar

disconnected. Changefuse orthermalrelar.

Motorrunsbutit gives

no pressure.

Flow is insufficient.

Impellersarewornout. Disconnectpumpandtakeit to

yourService Dealer.

Pumpblocked.

Thereis nosuction.

Motorrunsbutit gives

no pressure.

Foot valve not

submerged. Be suresuctionpipe is submerged.

Possible faults causes and solutions

Overall dimension

4.Electrical connection

The electric installation should be provided by a system of multiple separations with contact openings of at

least 3 mm.

The protection of the system will be made by a differential switch (1fn=30mA.) The electric cable must

correspond to the EEC(2) norm or to the type H07 RN-F according to VDE 0250.

The single phase motors have a built-in thermal protection.

Look at the schematic drawing on Fig(1) for a correct electrical connection.

5.Controls prior to the initial starting

Check that the tension and frequency of the electric supply correspond to that indicated on the technical

characteristics label.

Make sure that the shaft rotates freely.

Fill pump body with water, unscrewing slightly the priming plug.

Verify the motor sense of rotating as indicated on the fan cover.

THIS PUMP SHOULD NEVER BE DRYOPERATED.

6.Starting

Open all gate valves installed in the suction and connect the electric supply switch and wait for the priming

to be completed. If a foot valve has been installed. the priming will be instantaneous.

If motor fails to start or does not deliver water.

Refer to our trouble Shooting list with the possible problems and consequent actions to take. This

information will be found on the next pages.

7.Maintenance

Our electro pumps do not need any special maintenance.

Pump body should be drained during periods of low temperatures or long period of inactivity. If this inactivity

last longer, pump should be cleaned and kept in a dry and aired place.

3

m/h

l/min

150

125

100

75

50

25

H

(ft)

IMP.GPM

U.S.GPM

BJZ900-B

48

010203040506070 80

00.6 1.21.8 2.43.0 3.64.2 4.8

H

(psi)

H

(m)

BJZ075-B

0

8

40

32

24

16

0

10

20

30

40

50

60

BJZ100-B

Flow

BJZ037-B

0246810 12 14 16

02468101214161820

Head

100 170 197 128

90

358 177 178 88

G1 G1

98 184 155 148 80 357 200 202 98

9.5

10.5

11

ABDEFLHH1 H2 (Kg)

SIZE(mm)

7.5

BJZ075-B

BJZ100-B

BJZ900-B

BJZ037-B

B

A9

L

D

H

H2

H1

E

DNA

DNMF

Model

DNA DNM

10 20 30 40 50 60 70 80 90 100

60

50

40

30

20

10

0

Head (m)

Flow (l/min)

80L 60L 40L

10 20 30 40 50 60 70 80

60

50

40

30

20

10

0

Head (m)

Flow (l/min)

60L 40L

0 10 20 30 40 50 60 70 80 90 100

40

30

20

10

0

Head (m)

Flow (l/min)

SUBMERSIBLE

80L