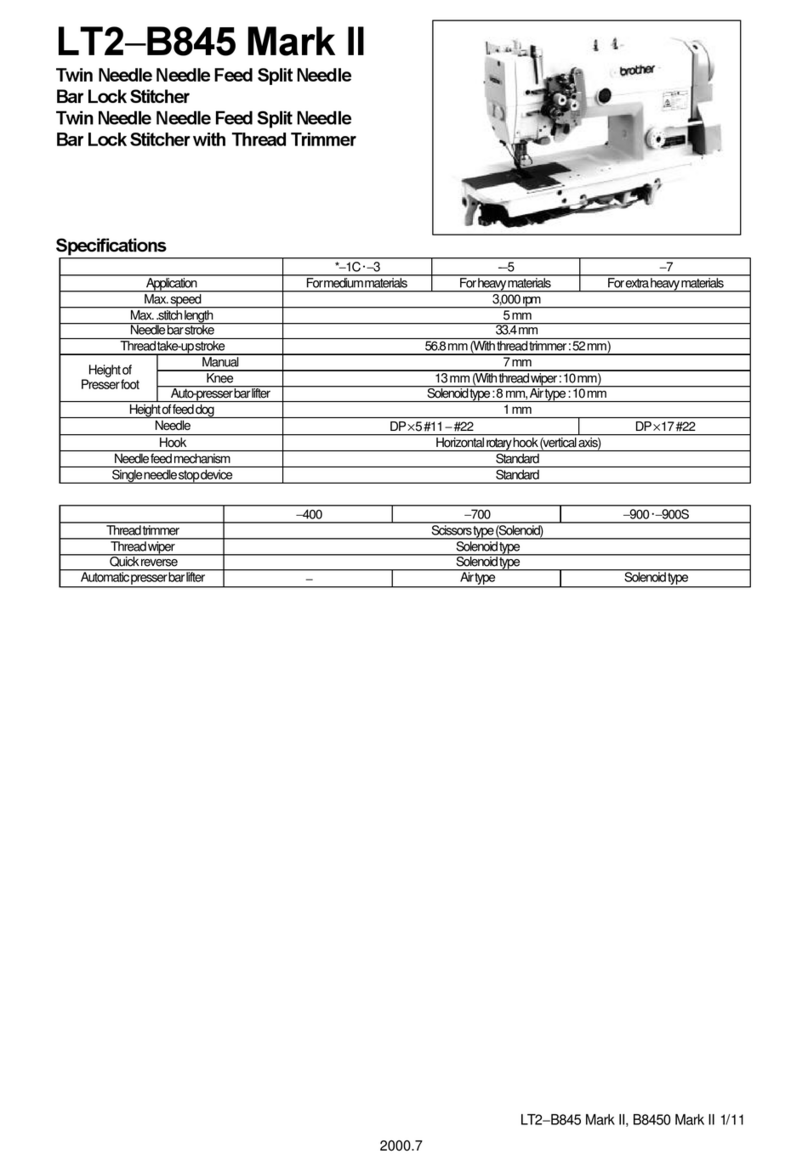

• Machine type: Single-head cylinder arm

• Number of needles: 9/12

• Maximum sewing speed: 1,200 spm

• Network capability: Connect multiple machines to

one computer for networking

• Stitch length: (0.1mm – 12.7mm)

• Rotary hook: Jumbo “M” style bobbin

• Maximum field size for: X-axis “width” Y-axis “height”

PRODUCT SPECIFICATIONS:

Number of units connected

to computer

Display Computer monitor

To 4 units

Computer control type Stand-alone type

N/A

Operation panel display

• Flat: 450mm 300mm

• Tubular: 450mm 300mm

• Border: 450mm 300mm

• Wide area caps: 360mm 85mm

• Power source/consumption: Single phase 120V,

220V, 230V, 240V

• Dimensions:At delivery: 34”(W) x 29”(L) x 55”(H)

• After setup: 41”(W) x 40”(L) x 58”(H)

• Weight: 195 kg. / 430 lbs.

QUICK-CHANGE

TUBULAR FRAME HOLDER

Two-piece tubular frame holder

allows for quick and easy conversion

from small to large tubular frames.

Frame holder can be adjusted to

accommodate a wide range of frame

sizes, from large jacket back frames

to small sock and pocket frames.

QUICK-CHANGE CAP

FRAME (optional)

All-in-one cap driver and frame

assembly allows for quick and easy

conversion from sewing caps to flat

or tubulargoods, again minimizing

machine downtime. Sew designs

from “ear to ear” with the wide-area

270-degree frames.

FLAT FRAME AND

REMOVABLE TABLE TOP

The table provides additional

support when stitching flat goods

such as towels or blankets.

BORDER (SASH)

FRAME (optional)

Frame for sewing unfinished

goods for patches or all-over

embroidery patterns.

©2007 BROTHER INTERNATIONAL CORPORATION

100 Somerset Corporate Blvd., Bridgewater, NJ 08807 Industrial Embroidery Machines: 1-800-432-3532, Fax: 1-908-575-3810,

Web site: www.brother.com The PAS Store: 1-877-850-7179, Fax: 1-877-667-8882, Web site: www.brothermall2.com