} )

Flexible handling of even previously

difficult-to-sew

materials

• The focus

of

machines with -1 specification is

on

sewing materials which are thin and difficult-to-sew. As a result

of

modification

of

mechanisms such

as

the needle

bar,

thread take-up, and rotary hook, materials which were previously difficult-to-sew

can

be sewn at

high speed.

(See

page

7.)

DD71

00-1

*

for

difficult-to-sew

For

new

synthetic materials specification B737-1 for thin materials

materials specification on the B737

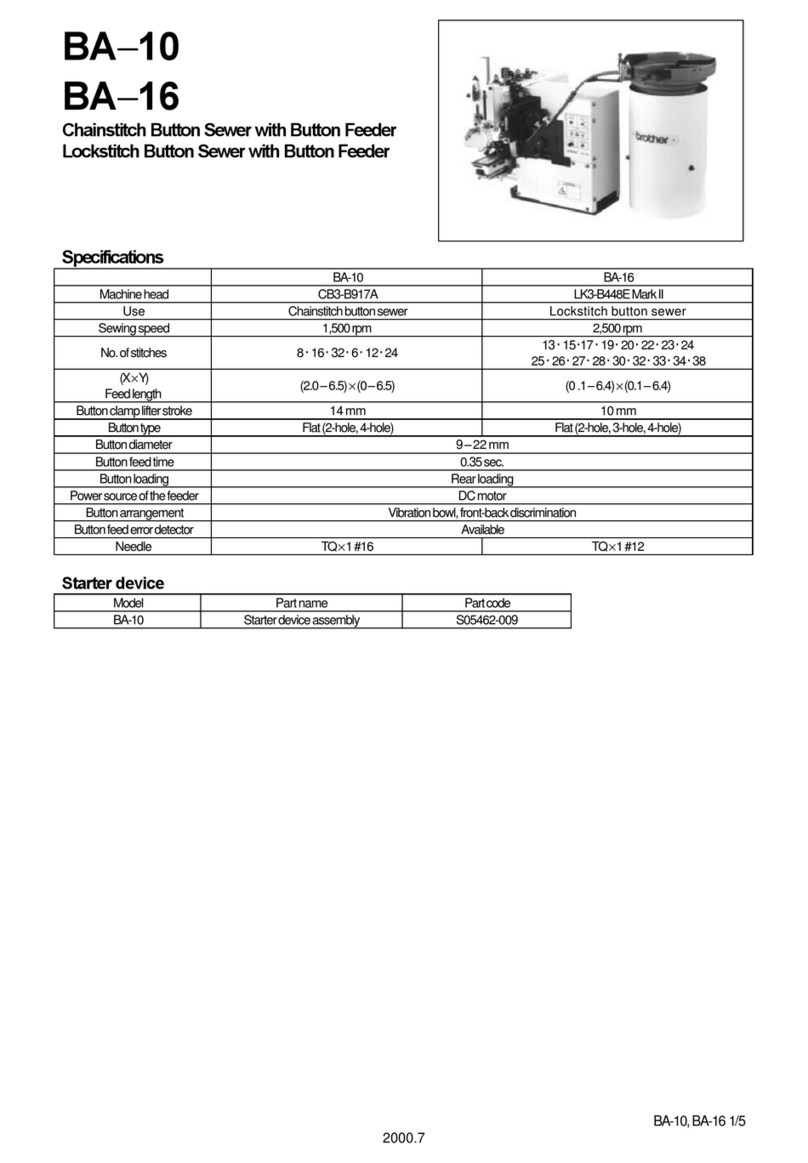

Needle bar stroke 29.0

mm

31.0

mm

31.0

mm

Needle

DB

X 1

#9

NS

DB

X 1 #10

NS

DB

X 1 #11

Rotary hook For thin material Plastic race (lubrication not required) For thin materials

Maximum sewing speed 4,000 spm 3,500 spm 4,000 spm

*It is possible to attach a plastic race (lubrication not required).

(In

this case, the maximum sewing speed is 3,500 spm.)

• The special tool for measuring the presser foot pressure is no longer needed. A tension gauge set enabling easy measurement

of

upper

and

lowerthread tensions is provided

as

an

optional part.

(See

page

8.)

Others

• The switches for

slow

start, correction stitch, and needle up/down stop position are provided

on

the operation panel so that you can

s~t

and check the current settings easily.

• After thread trimming, the machine can be stopped with the needle at its highest position by reversing the motor. This is useful when

changing the materials to be sewn, thick materials

in

particular.

(See

page

9.)

• Gauge parts for the 8737

and

those for other manufacturer's

can

be used.

• A lower thread detector (optional part) is provided to indicate the remaining lower thread. This is useful when sewing a product that

allows

no

overlapping or incomplete stitching.

(See

page

7.)

6