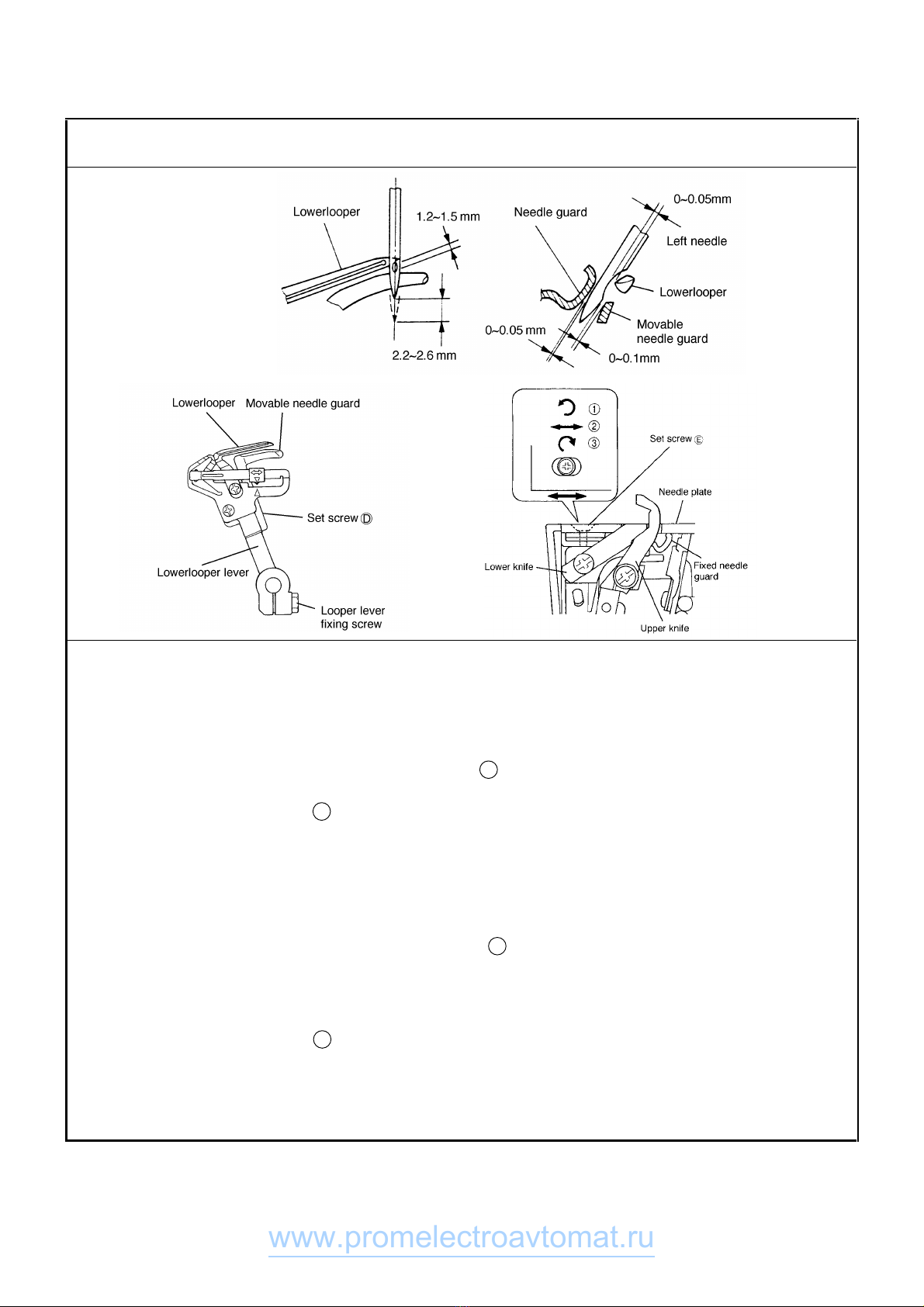

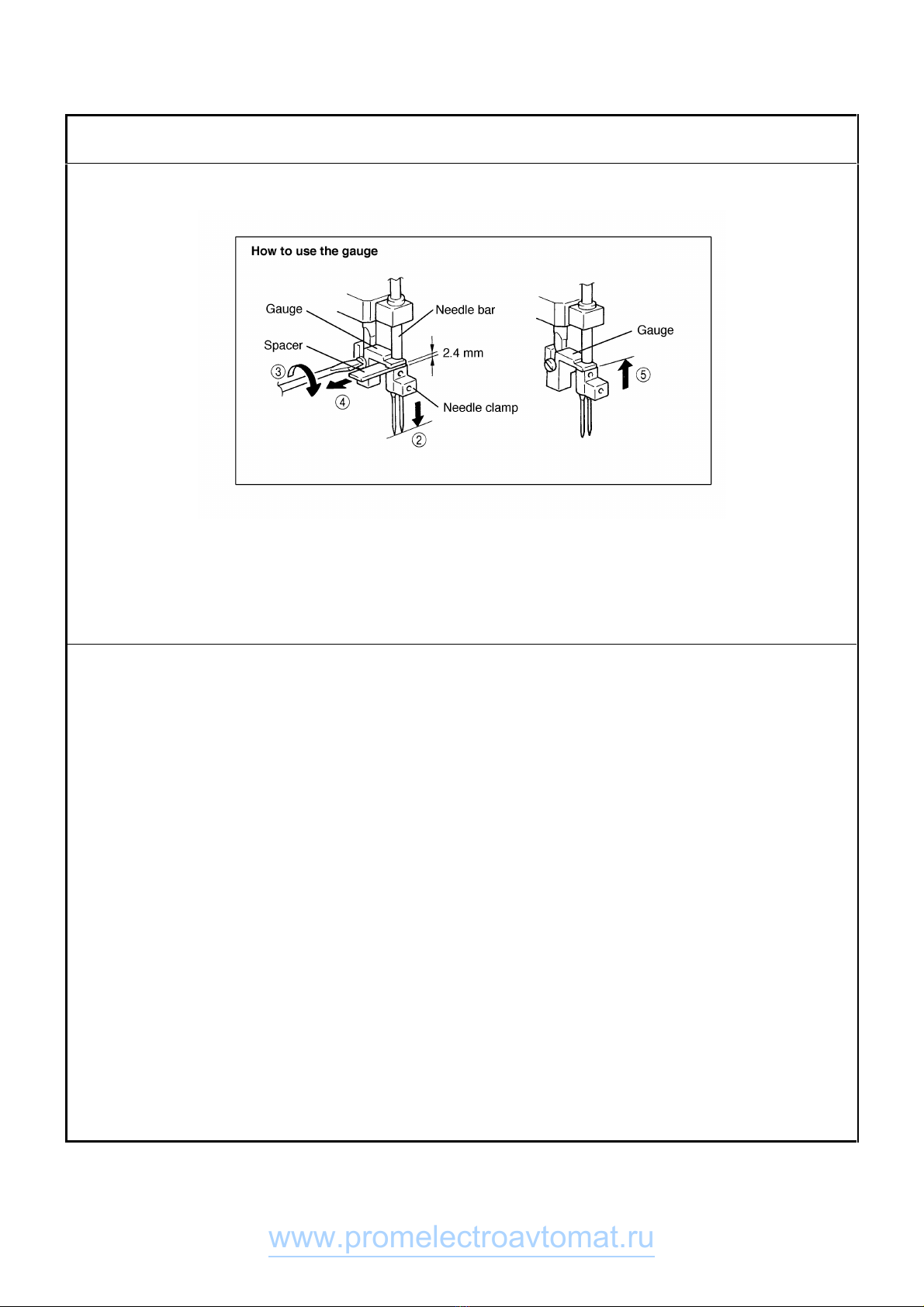

Brother Homelock 1034D User manual

Other Brother Sewing Machine manuals

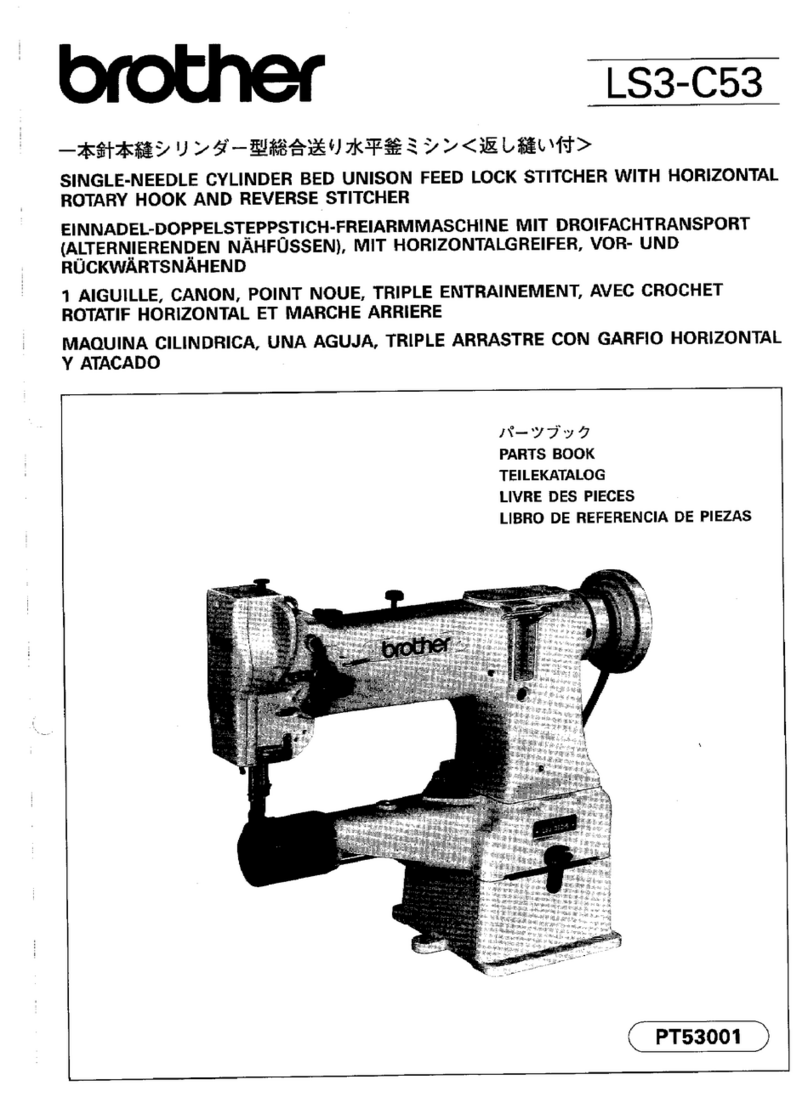

Brother

Brother 888-F52 User manual

Brother

Brother S-7300A-333P User manual

Brother

Brother Innov-Is M280D User manual

Brother

Brother BAS-342G PS User manual

Brother

Brother HE-800A User manual

Brother

Brother vx780 User manual

Brother

Brother RH-9820 User manual

Brother

Brother T-8421B User manual

Brother

Brother BAS-311A User manual

Brother

Brother S-7100A-403 User manual

Brother

Brother 885-V35/V37 User manual

Brother

Brother S-7200A User manual

Brother

Brother PQ-1300 User manual

Brother

Brother S-7000DD User manual

Brother

Brother PR-600 User manual

Brother

Brother XL5010 User manual

Brother

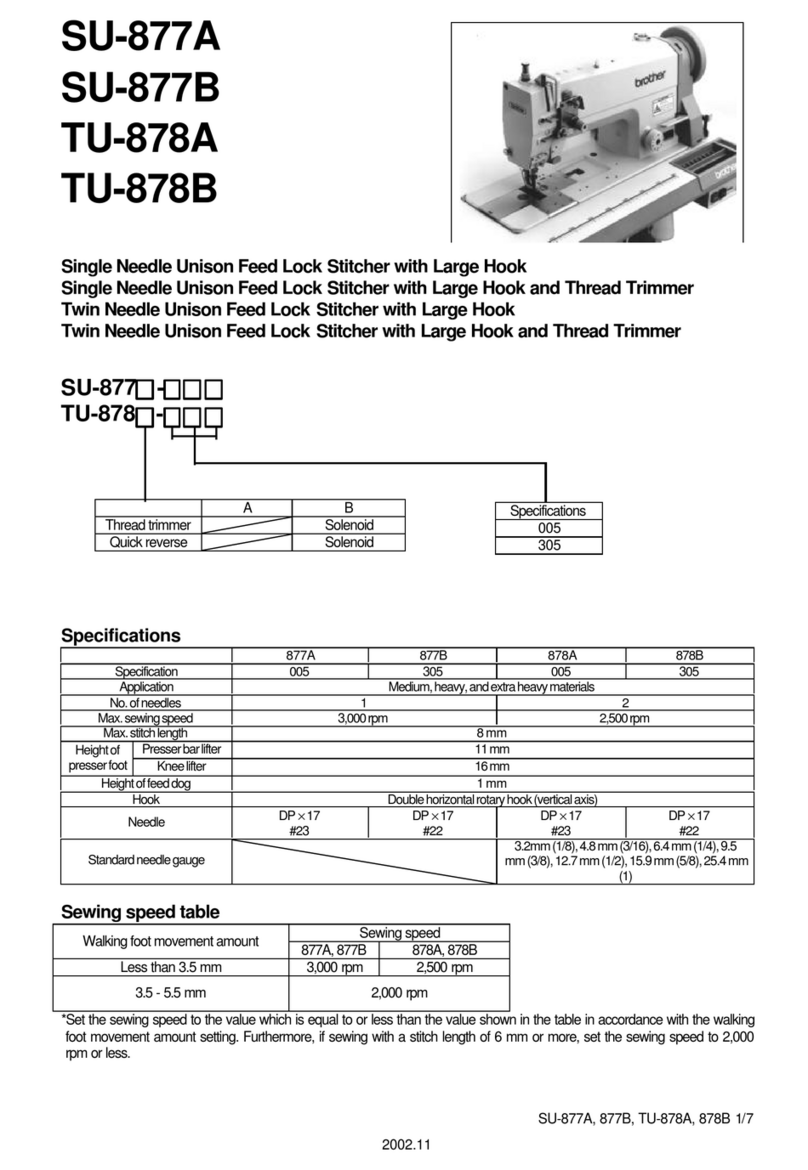

Brother SU-877A User manual

Brother

Brother NV10 User manual

Brother

Brother FD6-B941 User manual

Brother

Brother 888-G00 User manual