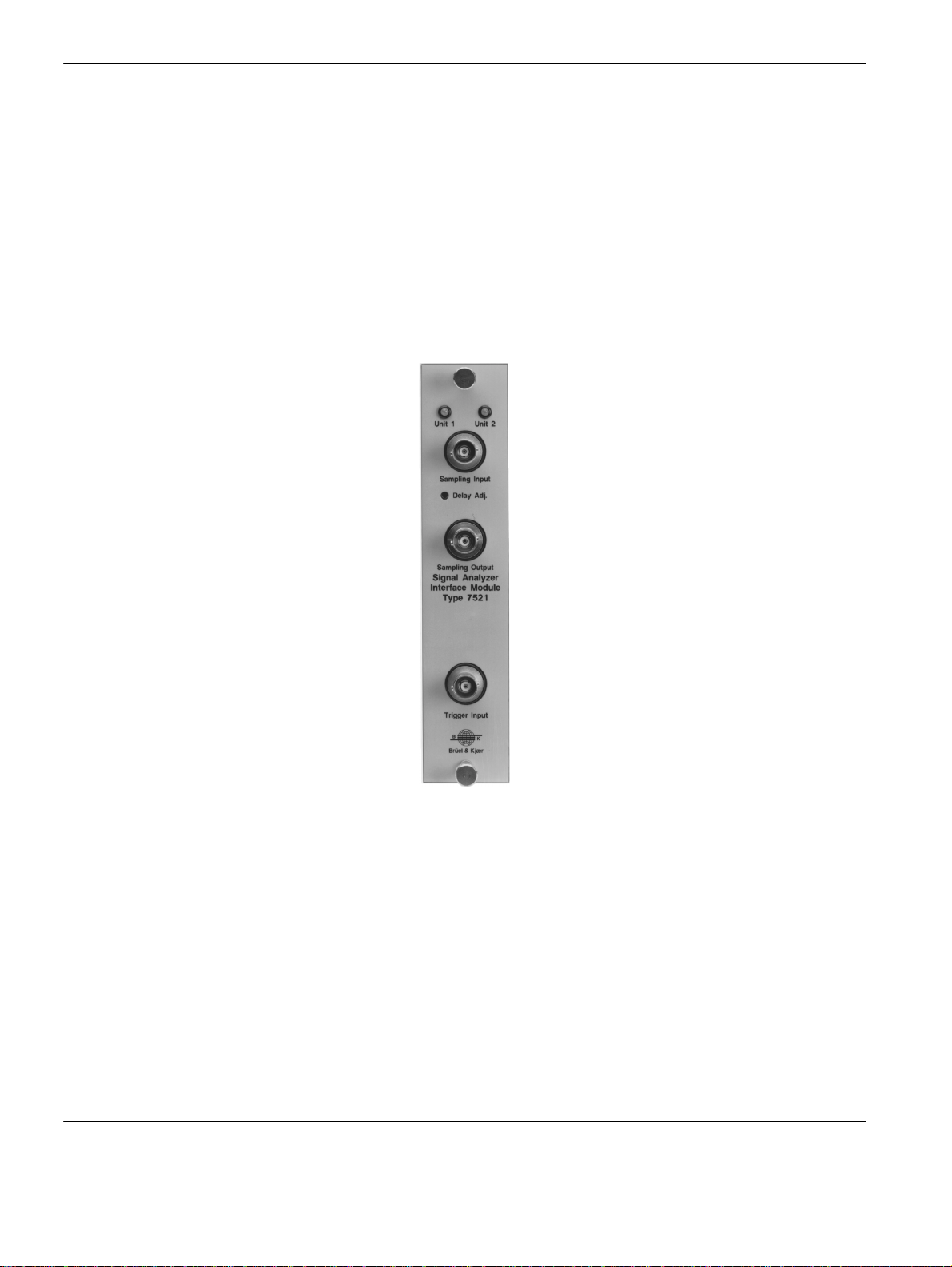

Signal Analyzer Interface Unit Type 7521

Service Manual

BI5040–12e 0−3

Contents

1. General Information.................................................................................................. 1–1

1.1 Introduction................................................................................................................. 1–2

1.2 Edition Number........................................................................................................... 1–2

1.3 Safety ........................................................................................................................... 1–3

1.4 Service Policy and FRP Number ................................................................................ 1–3

1.5 Special Tools and Equipment..................................................................................... 1–3

2. Service Note...................................................................................................................... 2–1

2.1 On-line Editions of the Service Manual..................................................................... 2–2

2.2 Printed Editions of the Service Manual..................................................................... 2–2

3. Checking Procedure................................................................................................... 3–1

3.1 Preparation.................................................................................................................. 3–2

3.2 Procedure..................................................................................................................... 3–2

The Digital Part of the 7521 .................................................................................. 3–2

The Analog Part of the 7521.................................................................................. 3–3

4. Adjustment Procedure............................................................................................. 4–1

4.1 Introduction................................................................................................................. 4–2

4.2 Preparation.................................................................................................................. 4–2

4.3 Procedure..................................................................................................................... 4–2

The Trigger Input................................................................................................... 4–2

The Sampling Input ............................................................................................... 4–3

The Delay Adjustment ........................................................................................... 4–4

5. Mechanical Parts.......................................................................................................... 5–1

5.1 Chassis Parts............................................................................................................... 5–2

5.2 Spare Parts.................................................................................................................. 5–3