Housing Disassembly

Step 1: Disconnect power source, ensure all pressure is removed from pump head assembly and isolate

fluid discharge and suction lines. Open and remove priming valve. Disconnect fluid discharge

and suction lines. Drain oil from gear box.

Step 2: Remove wing screws, washer seals, cover and gasket.

Step 3: Remove plunger pin. Remove pump head assembly from housing. See Pump Head Disassembly

instructions for further disassembly of pump head assembly.

Step 4: Loosen both setscrews and remove stroke adjustment drive gear. Remove stroke adjustment

assembly by unscrewing stroke adjustment spindle from housing.

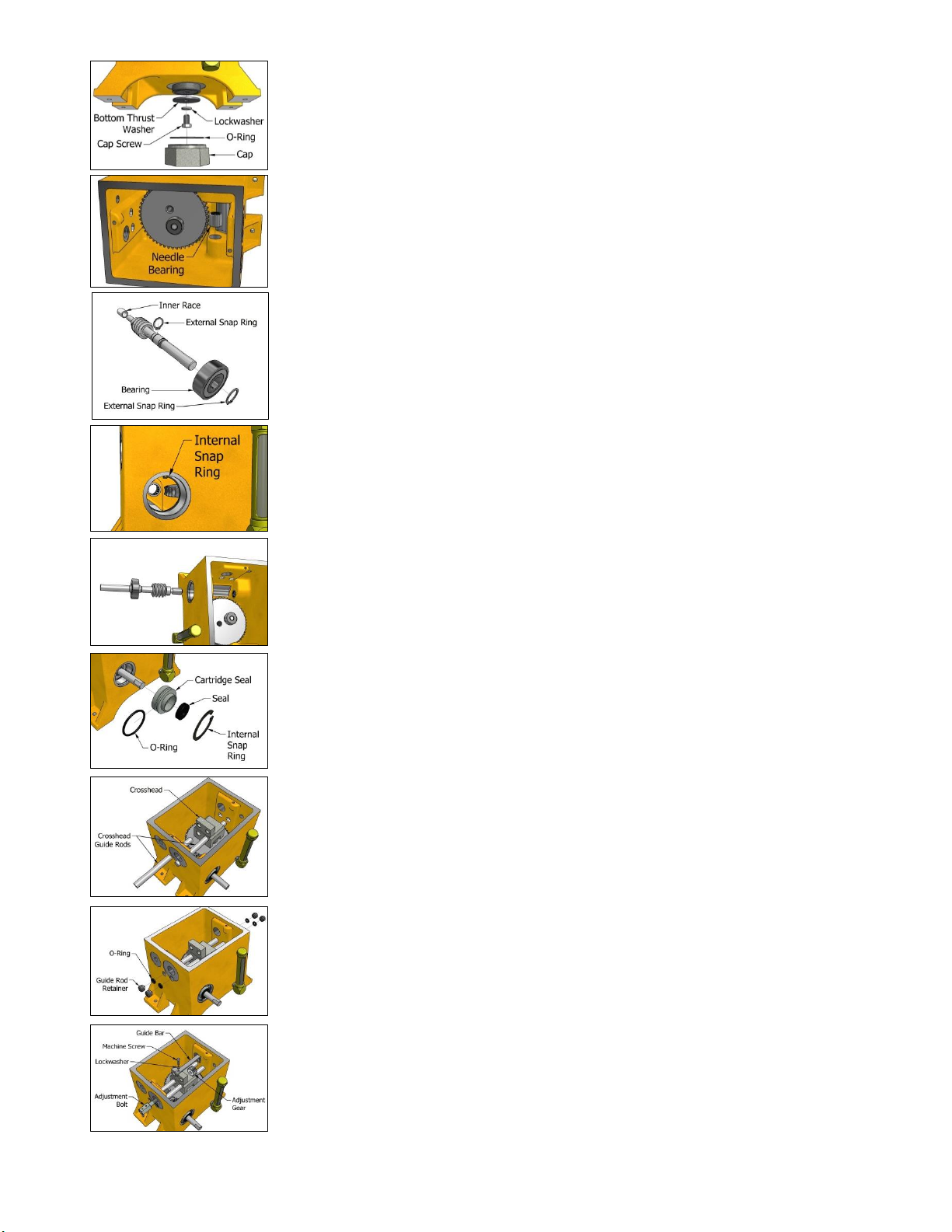

Step 5: Remove all 4 rod retainers and 4 O-rings.

Step 6: Remove both crosshead guide rods by pushing them through crosshead.

Step 7: Remove crosshead assembly from housing. Remove screw, guide bar, stroke adjustment gear

and adjustment bolt from crosshead.

To remove worm gear and shaft.

Step 8: It is not necessary to remove the crosshead assembly in order to remove the worm gear and

shaft.

Step 9: Disconnect coupling and remove motor from base. Note: It is best to remove the entire gear box

from the base.

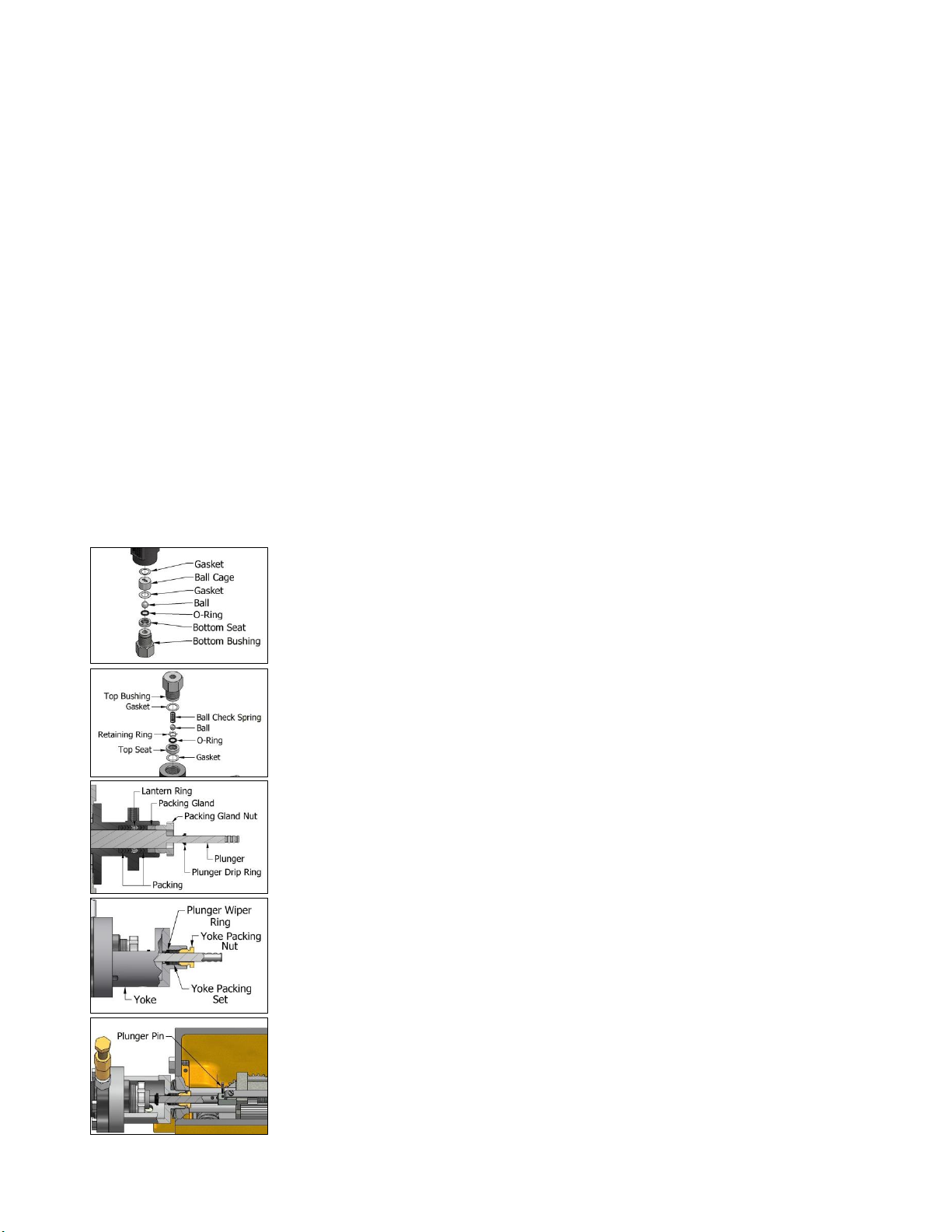

Step 10: Remove the outside snap ring and pipe plug.

Step 11: Remove worm gear shaft by carefully driving it out from the small end located under the pipe

plug. Be careful not to remove the needle bearing at this time. As the shaft is being driven out,

care should be exercised to ensure that the worm gear is rotating, allowing the gear teeth to

walk and disengage.

Step 12: As the shaft is driven out, it will force out the cartridge seal and ball bearing.

Step 13: Remove the outer snap ring from the shaft and remove the ball bearing.

Step 14: Remove seal from cartridge seal. Note: Removal of seal will result in damage to the seal and

require replacing.

Step 15: Remove needle bearing from housing.

To remove worm gear.

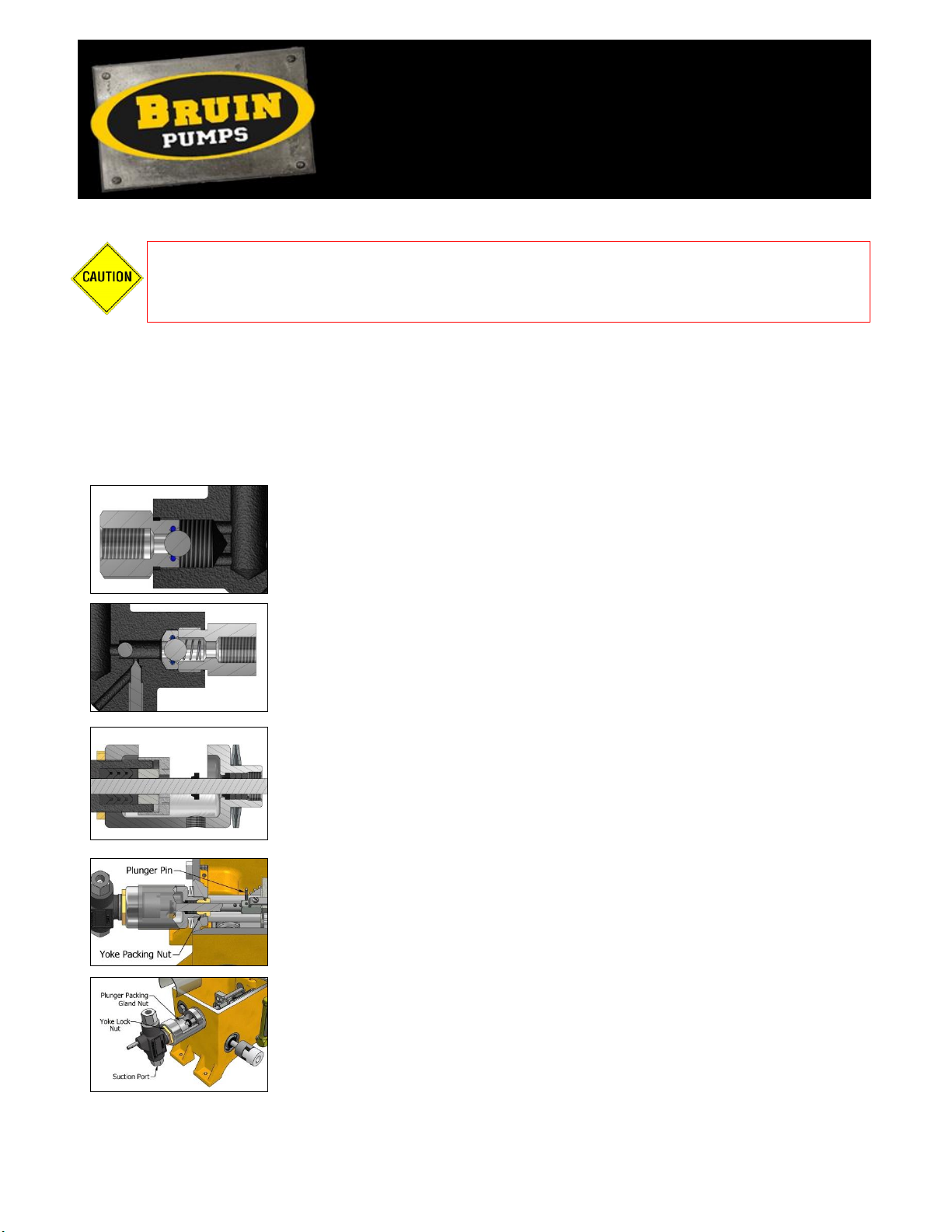

Step 16: Unscrew cap from bottom of housing.

Step 17: Unscrew machine screw from worm gear and remove lockwasher and thrust washer.

Step 18: Remove worm gear from lower bearing. Remove lower bearing from housing.

*** *** *** *** ***

INSPECTION

Inspect all components for damage. Replace or repair parts as necessary. The following is a

guideline of what to inspect:

Inspect all threads, seals and packing for damage.

Inspect body seal areas for corrosion, pitting, or damage. Seal areas on the body include the

packing area and the area below the top seat and ball cage.

Inspect balls, top seat, bottom seat and ball check spring for corrosion or damage.

Inspect plunger for wear, scarring, or damage.

Inspect worm gears and bearing for wear or damage.

Inspect housing and all other components for damage.

9001-20 Street NW, Edmonton, Alberta, Canada T6P 1K8 Phone: 780-430-1777 Fax: 780-449-5233