Contents

1 Introduction.................................................................................................................5

1.1 Purpose of this manual................................................................................................................. 5

1.2 Target audience.............................................................................................................................5

1.3 Validity of these instructions......................................................................................................... 5

1.4 Keeping of documents.................................................................................................................. 5

1.5 Symbols and text style rules.........................................................................................................6

1.5.1 Specified symbols........................................................................................................... 6

1.5.2 Text style rules................................................................................................................ 6

1.6 For your safety.............................................................................................................................. 7

1.6.1 Dangers and safety measures........................................................................................7

1.6.2 Warnings......................................................................................................................... 8

1.6.3 Regulations......................................................................................................................8

1.6.4 Conformity....................................................................................................................... 9

1.6.5 Obligations of our Natural Power Partners.....................................................................9

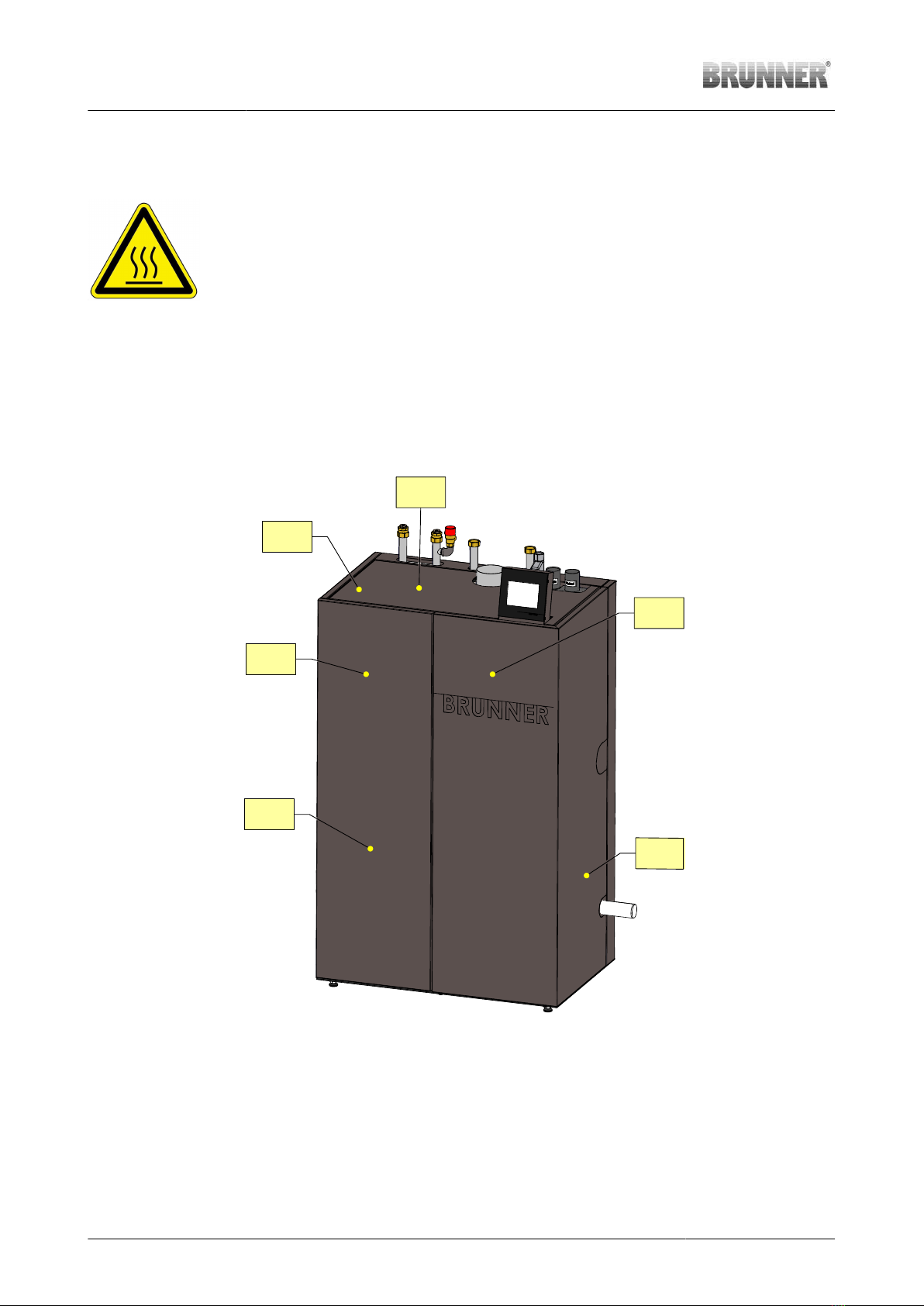

1.6.6 Surfaces with possible risk of burns.............................................................................10

2 Product description..................................................................................................11

2.1 Intended use................................................................................................................................11

2.2 Type plate....................................................................................................................................12

2.3 Overview of the boiler................................................................................................................. 13

2.4 Functional description..................................................................................................................14

2.5 Safety concept.............................................................................................................................14

2.6 Fuel and water quality requirements.......................................................................................... 16

2.6.1 Pellets............................................................................................................................16

2.6.2 Heating water................................................................................................................ 17

3 Operation basics...................................................................................................... 18

3.1 Licenses.......................................................................................................................................18

3.2 Touch-sensitive display................................................................................................................19

3.3 Display overview..........................................................................................................................20

3.3.1 Combustion chamber - display views...........................................................................21

3.3.2 Ash box - display views................................................................................................22

3.3.3 Buffer tank display views.............................................................................................. 22

3.4 Buttons.........................................................................................................................................22

3.5 Display views Pellet storage....................................................................................................... 25

3.5.1 Daily pellet container.................................................................................................... 25

3.5.2 Annual pellet hopper/weekly hopper............................................................................ 27

3.6 Own settings................................................................................................................................29

3.6.1 Individualisierung des Displays.....................................................................................29

3.6.2 Locking the boiler - for filling the pellet store............................................................... 35

3.6.3 Exhaust gas test........................................................................................................... 36

3.6.4 Communication of the system...................................................................................... 38

3.6.5 Selecting or creating new heating programs................................................................ 39

3.6.6 Setting the program for hot water.................................................................................41

3.6.7 Absence time................................................................................................................ 42

© 2023 Brunner GmbH Instructions for Use BPH 4/17 (2.29) 3