1

© Brunswick Bowling & Billiards Corp. 2005. All rights reserved.

Lane Shield

Care Instructions

June 2005 61-900023-000

Introduction

Brunswick LaneShield is a specially designed and formulated, high impact, polymer plastic. Teflon has been

blended into the polymer to give LaneShield a durable, long lasting, and consistent, bowling surface.

Note: For optimum performance of your LaneShield product, it is important to maintain steady temperature

and humidity levels within your bowling center after LaneShield has been installed. The recommended

humidity is 45% ±5%. The recommended temperature is 75°F ±5°F. Failure to maintain these

recommended temperature and humidity levels will cause LaneShield to expand and contract, which may

cause "waving" of the LaneShield.

Conditioners and Cleaners

Use only bowling industry approved products for LaneShield. Other oils, lubricants, and cleaning supplies may

damage LaneShield and void your warranty.

Always follow the directions supplied by the manufacturer of all conditioners and cleaners. If there is any question

as to whether or not a new lane maintenance product can be used, contact your Brunswick Product Specialist.

Cleaning Materials to be Avoided

Solvents or solvent based cleaners, (such as pinsetter cleaners, toulene, xylene, etc.), should never be used on

LaneShield. Solvent based materials will cause damage to LaneShield, such as blistering.

Other Conditions to Avoid

Do not roll any carts with heavy loads, such as those used for pinsetter installation, down lanes with LaneShield in

place. Damage to LaneShield could result.

Bleachers for tournaments or other similar, temporary structures should not be built or placed on LaneShield.

Damage to LaneShield could result.

Use proper mats and carpets to avoid abrasive particles from being tracked onto approach or lane.

Bowling Ball Maintenance Program

A good maintenance program to keep house balls repaired, (all holes should have beveled edges and sharp edges/

cracks should be filled with ball plug) will reduce potential abrasion and/or damage to LaneShield.

Maintenance Procedure

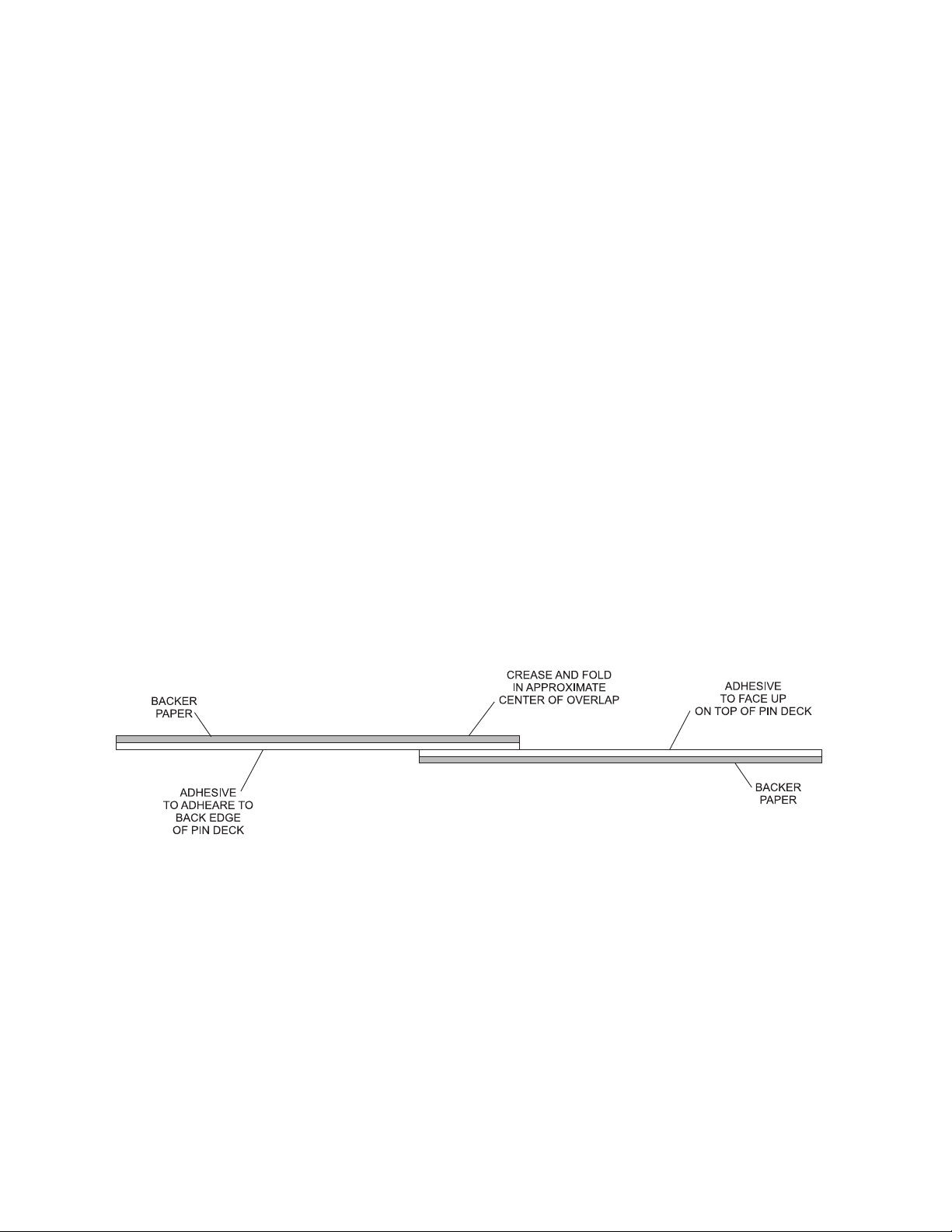

1. If your lane machine causes any movement of the LaneShield, pushing trapped air ahead of the lane

machine, it will be necessary to use a towel bar, wrapped in a clean, terry cloth towel, and push the

LaneShield flat, starting at the foul line and pushing to the end of the pin deck.