10

NOTE: The model plug takes priority over factory model

information input at the factory. If the model plug is removed after

initial power up, the unit will operate according to the last valid

model plug installed, and flash the appropriate fault code

temporarily.

High Pressure Switch Protection

The outdoor unit is equipped with high pressure switch. If the

control senses the opening of a high pressure switch, it will

respond as follows:

1. De--energize the contactor.

2. Keep the outdoor fan operating for 15 minutes.

3. Display the appropriate fault code (see Table 7).

4. After a 15 minute delay, if there is a call for cooling or heat-

ing and HPS is reset, the contactor is energized.

5. If HPS has not closed after a 15 minute delay, the outdoor

fan is turned off. If the open switch closes anytime after the

15 minute delay, then resume operation with a call for cool-

ing or heating at a temporary reduced capacity.

6. After each HPS trip fault, the compressor will operate at a

reduced RPM/Capacity. When the HPS trips at the mini-

mum RPM, the unit will be locked out on system malfunc-

tion code 84 for 4 hours.

7. In the event of a high--pressure switch trip or high--pressure

lockout, check the refrigerant charge, outdoor fan operation,

and outdoor coil (in cooling) for airflow restrictions, or in-

door airflow in heating.

Low Pressure Protection

The outdoor unit is equipped with low pressure transducer. If the

control senses a low pressure per the table below, it wil respond as

follows:

Cooling Low Prssure (3 minute operation) Cool Mode <= 55 psig

Low Pressure (instantaneous) <13 psig

1. Display fault code 32 on Status LED and wall control.

2. If a demand persists after the 15--minute delay and the

pressure has reached the operation level, then resume opera-

tion. Reset the 15 minute timer, clear the displayed fault

code and communicate cleared error to the wall control.

Status LED reverts to operation code display.

3. If a demand persists after the 15 minute delay but the pres-

sure has not recovered, turn off the ODF. If the pressure

recovers any time after the 15 minute delay, resume opera-

tion. Reset the 15 minute timer, clear the displayed error

code and communicate cleared error to the wall control.

Status LED reverts to operation code display.

4. If a pressure drops below the instantaneous level three (3)

consecutive times, lock out operation for 4 hours and dis-

play the system malfunction code 83 and communicate

lockout status to the wall control. The trip counter will reset

to zero if 15 minutes of successful operation occurs before

the 3rd trip is recorded.

5. In the event of a low pressure trip or low pressure lockout,

check the refrigerant charge and indoor airflow.

Brown--Out Protection

If the line voltage is less than 187v for at least 4 seconds, the

contactor and fan relay are de--energized. Compressor and fan

operation are not allowed until voltage is a minimum of 190v. The

control will flash the appropriate fault code (see Table 7).

230V Line (Power Disconnect) Detection

If there is no 230v at the contactor when the indoor unit is powered

with a cooling or heating demand, the appropriate fault code is

displayed. Verify the disconnect is closed and 230v wiring is

connected to the unit.

Inverter Voltage Sensing

The control board senses the presence or absence of 230 V through

the feedback from inverter. The control monitors the high voltage

to the inverter. Voltage should be present anytime the contactor is

energized and voltage should not be present when the contactor is

de--energized.

Temperature Thermistors

Thermistors are electronic devices which sense temperature. As the

temperature increases, the resistance decreases. Thermistors are

used to sense outdoor air (OAT), coil temperature (OCT) and the

suction line thermistor (OST) located between the reversing valve

and the accumulator.

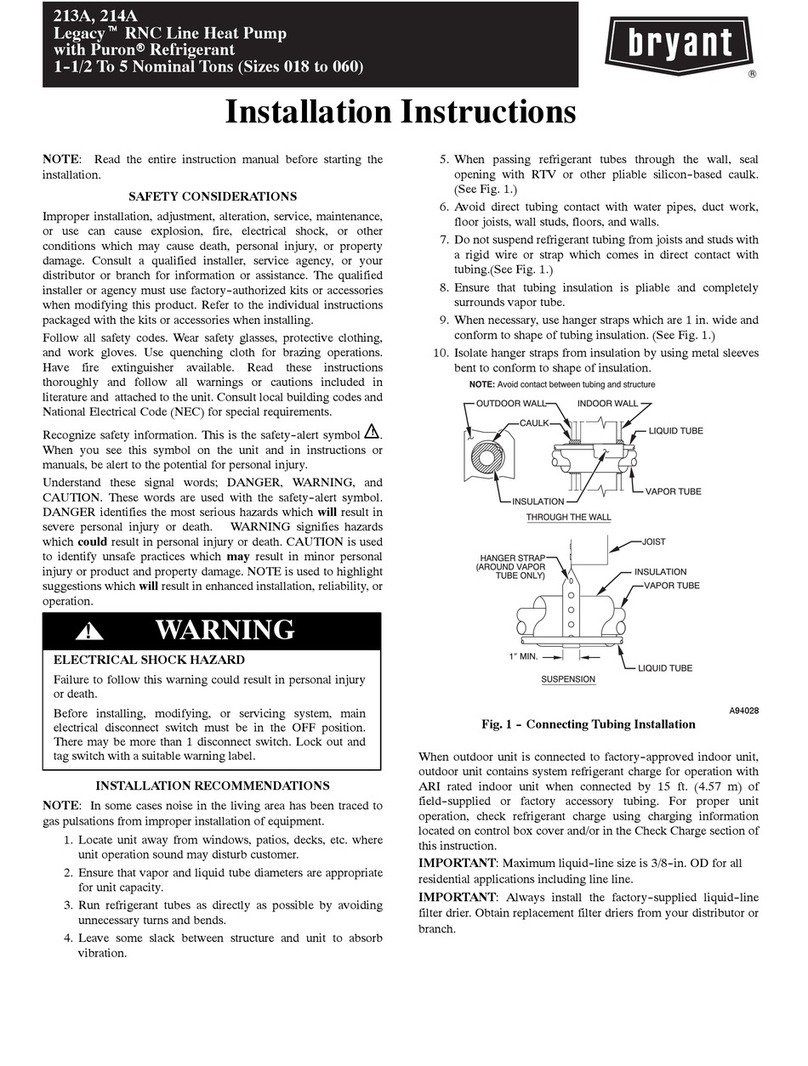

Refer to Table 4 and Fig. 10 for resistance values versus

temperature.

Table 4 – Resistance Values versus Temperature

TEMPERATURE RESISTANCE (ohms)

25.0° C (77.0° F) 10.0 + / - 2.3%

0.0° C (32.0° F) 32.6 + / - 3.2%

-28.0° C (-18.4° F) 85.5 + / - 3.4%

0

10

20

30

40

50

60

70

80

90

0 20 40 60 80 100 120

TEMPERATURE (DEG. F)

RESISTANCE (KOHMS)

THERMISTOR CURVE

A91431

Fig. 10 -- Thermistor Resistance Versus Temperature

If the outdoor air or coil thermistor should fail, the control will

flash the appropriate fault code (see Table 7.)

IMPORTANT: The outdoor air thermistor, coil thermistor and

suction thermistor should be factory mounted in the final

locations. Check to ensure thermistors are mounted properly

(See Fig. 11, 12 and 13).

Thermistor Sensor Comparison

The control continuously monitors and compares the outdoor air

temperature sensor and outdoor coil temperature sensor to ensure

proper operating conditions. The comparison is:

SIn cooling if the outdoor air sensor indicates 10_F(5.6_C)

warmer than the coil sensor (or) the outdoor air sensor indicates

20_F(11_C) cooler than the coil sensor, the sensors are out

of range.

If the sensors are out of range, the control will flash the appropriate

fault code as shown in Table 7.

The thermistor comparisons are not performed during low ambient

cooling or defrost operation.

Failed Thermistor Default Operation

Factory defaults have been provided in the event of failure of

outdoor air thermistor (OAT) and/or outdoor coil thermistor

(OCT).

If the OAT sensor should fail, low ambient cooling will not be

allowed and the one--minute outdoor fan off delay will not occur.

Defrost will be initiated based on coil temperature and time.

If the OCT sensor should fail, low ambient cooling will not be

allowed.

Count the number of short and long flashes to determine the

appropriate flash code. Table 7 gives possible causes and actions

related to each error.