IV. FIELD CONNECTIONS

A. Condensate Disposal

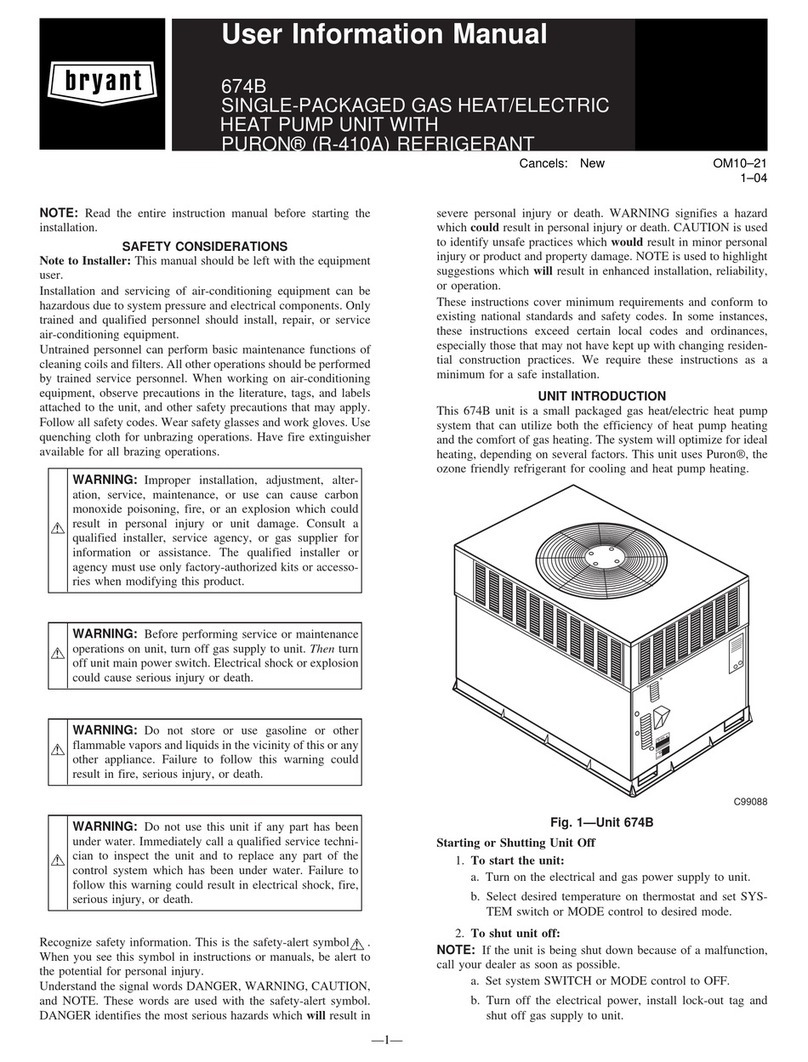

Units must have an external trap added. See Fig. 7. A

3

⁄

4

-in.

FPT connection is located on the side of the unit. Use a trap

at least 100 mm (4-in.) deep, and protect against freeze-up.

If drain line is run to a drain, pitch line away from unit at

25 mm (one in.) per 3 m (10 ft) of run. Do not use a pipe size

smaller than the unit connection.

B. Field Duct Connections

NOTE: The design and installation of the duct system must

be in accordance with local codes and ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Remove appropriate panels from unit to obtain either

horizontal or vertical discharge. If units are installed in

horizontal discharge applications, remove vertical dis-

charge duct covers, save screws, and install covers on

vertical duct openings.

2. Select and size ductwork, supply-air registers, and return-

air grilles according to local codes and practices.

CAUTION: When drilling the duct system fastening

holes into the side of the unit for duct flanges, use ex-

treme care not to puncture the coil or coil tubes. See

Fig. 8.

3. Use flexible transition between rigid ductwork and unit

to prevent transmission of vibration. The transition may

be screwed or bolted to duct flanges. Use suitable gas-

kets to ensure weather- and airtight seal.

4. When horizontal return is used, install external, field-

supplied air filters in return-air ductwork where they

are easily accessible for service. Recommended filter sizes

are shown in Tables 1a and 1b.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed.Avoid abrupt

duct size increase or decreases.

6. Adequately insulate and weatherproof all ductwork lo-

cated outdoors. Insulate ducts passing through uncon-

ditioned space, and use vapor barrier in accordance with

local minimum installation standards for heating and

air conditioning systems. Secure all ducts to building

structure.

A minimum clearance to combustibles is not required

around ductwork on vertical discharge units. On hori-

zontal discharge units, a minimum clearance of 25 mm

(1 in.) is required for the first 300 mm (12 in.) of

ductwork.

7. Flash, weatherproof, and vibration isolate all openings

in building structure in accordance with local codes and

good building practices.

C. Electrical Connections

WARNING:The unit cabinet must have an uninter-

rupted, unbroken, electrical ground to minimize the pos-

sibility of personal injury if an electrical fault should

occur. This ground may consist of electrical wire con-

nected to the unit ground lug in the control compart-

ment, or conduit approved for electrical ground when

installed in accordance with U.S.A. National Electrical

Code (Ref:ANSI/NFPA70-1987) or equivalent local elec-

trical codes. Do not use gas piping as an electrical ground.

Failure to adhere to this warning could result in per-

sonal injury.

CAUTION: Failure to obey the following pre-

cautions could result in damage to the unit being

installed:

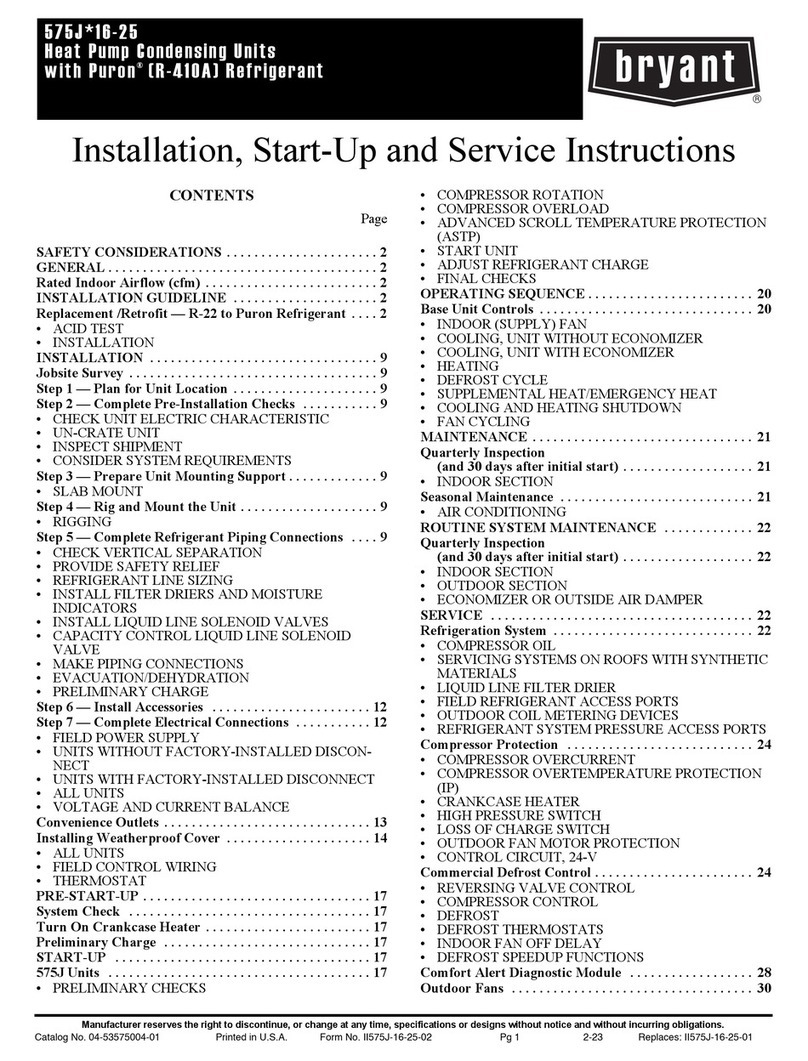

Field Power Supply (Fig.9-11)

1. Make all electrical connections in accordance with local

electrical codes governing such wiring. Refer to unit wir-

ing diagram.

2. A unit disconnect switch is required within sight from

the unit. The disconnect switch may be mounted on

the unit corner post (see Fig. 2). When mounting dis-

connect switch, be sure the unit rating plate is not

obstructed.

3. Use only copper or copper clad conductor for connec-

tions between field-supplied electrical disconnect switch

and unit. Use of aluminum wire is not recommended.

Maximum wire size is number 2 AWG (American Wire

Gage, U.S.A.) on units without heat, and 350 kcmils on

units with electric heater and single point box. See

Table 2 for wire conversions.

4. Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Table 3). On 3-phase units, voltages between phases

must be balanced within 2% and the current within 10%.

Use the formula shown in Table 3, Note 3 to determine

NOTE: Trap should be deep enough to offset maximum unit static dif-

ference. A 100-mm (4-in.) trap is recommended.

Fig. 7 — External Trap Condensate Drain

Fig. 8 — Location of Coil Area

Not to be Drilled

—8—