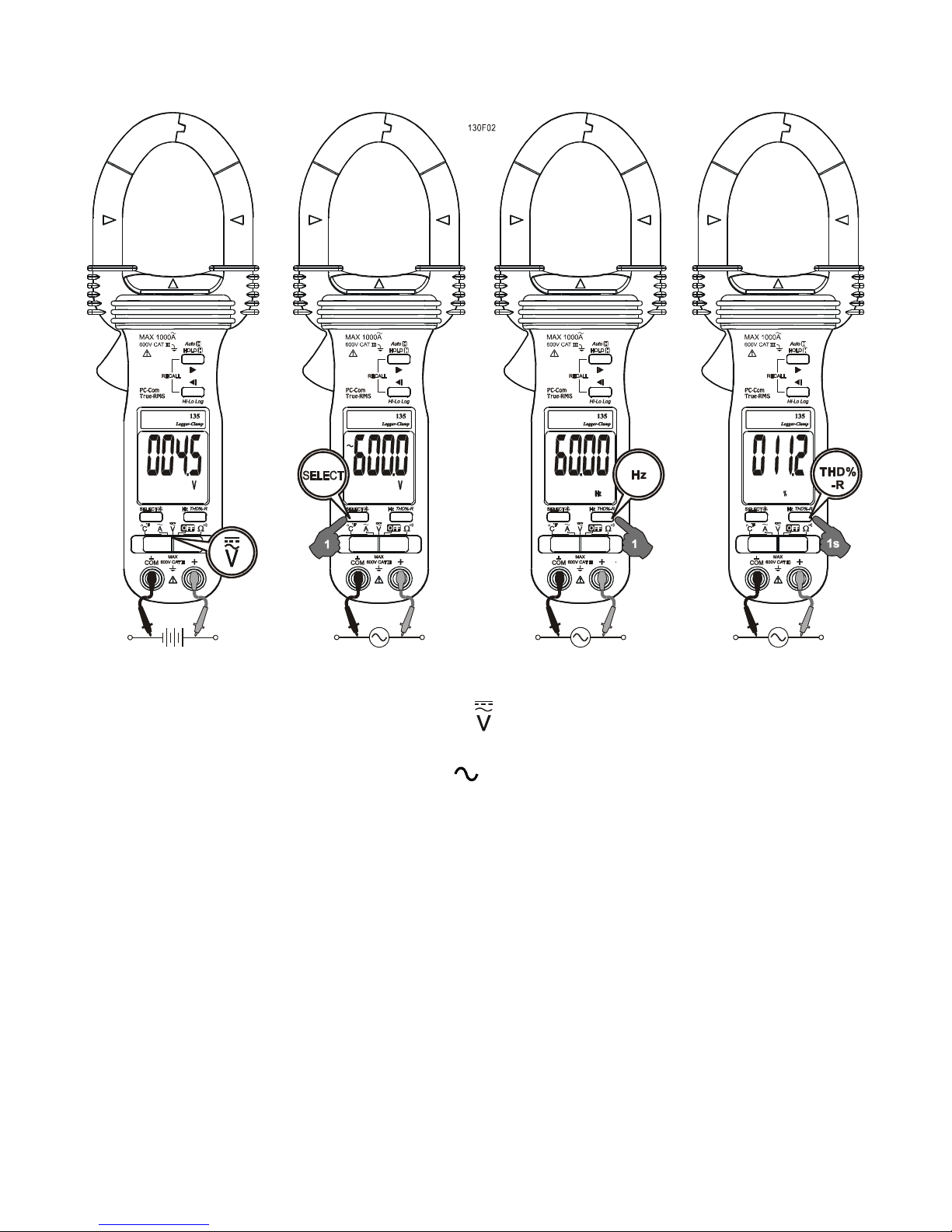

Lo-reading “ ” (the lowest reading) of that one-minute item interval. Press-and-hold the

button can quickly scroll the logged items. The meter gives short beeps when the last (or the

first) item is reached.

Note:

1.

When the meter memory is full or the meter battery is low, the meter will stop (end) the

Hi-Lo logging session and go back to the normal measuring mode.

2.

The data is stored to the non-volatile memory shortly after every one-minute item interval

to maximize data safety. However, the end-of-data sign can be stored only after the Hi-Lo

logging session is ended with a session stop “ ”. Therefore, always stop “ ” the Hi-Lo

logging properly before sliding the slide-switch function-selector to the next function position.

3.

After the Hi-Lo logging session is ended, you can switch off the meter for transportation,

storage, or even battery changing. The logged data can also be downloaded to PC

computers through the optional purchase BR13X PC interface kit. Also see RS232C PC

computer interface capabilities section.

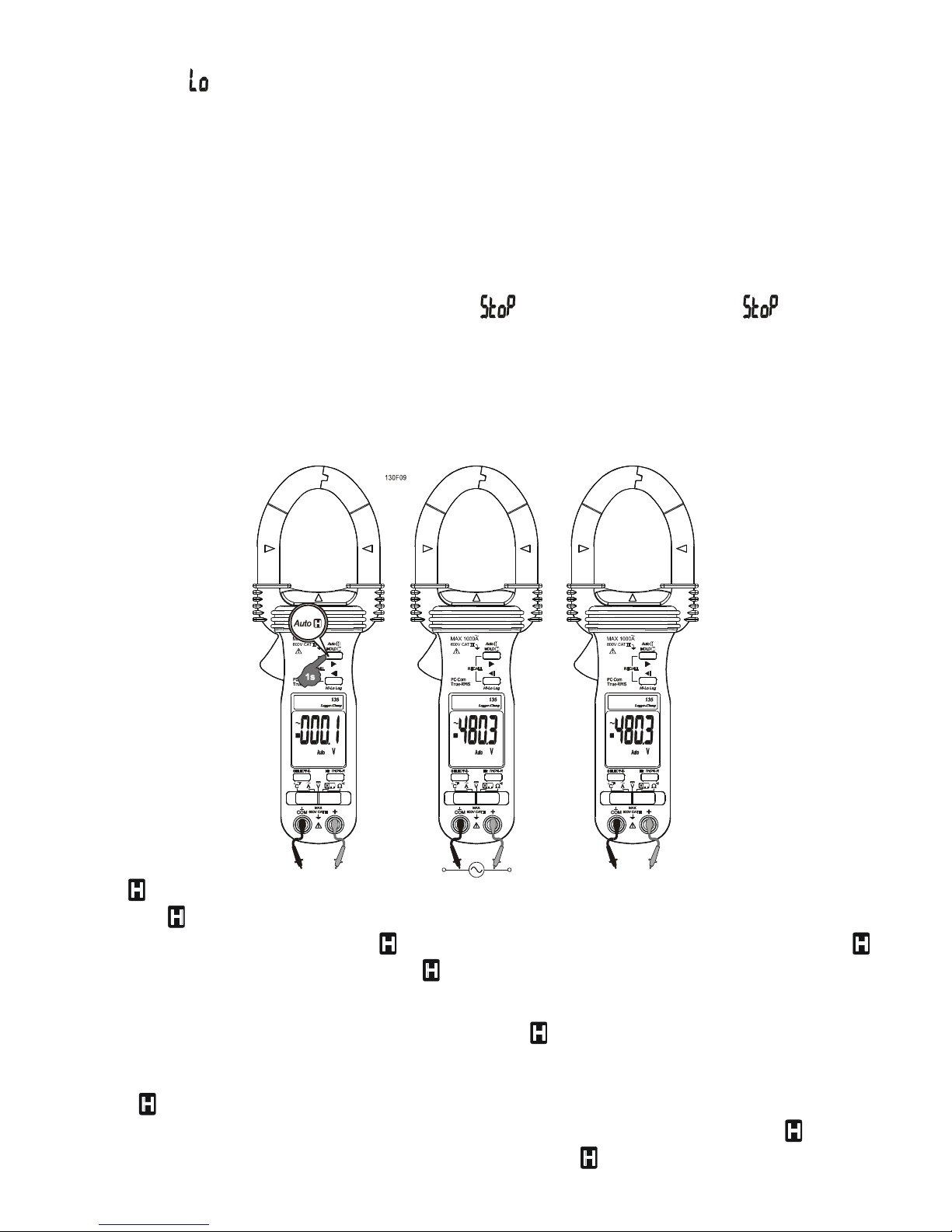

Auto feature

The Auto (Automatic-Hold) feature automatically captures and displays significant stable

readings. Press and hold the Auto button for one second or more to toggle to the Auto

mode. The LCD annunciators “Auto” & “ ” turn on.

WARNING

To avoid electric shock hazard, do not use the Auto (Automatic-Hold) mode to determine

if a circuit is live. Unstable readings will not be captured and displayed.

H LD feature

The Hold feature freezes the display for later viewing. Press the H LD button

momentarily to toggle to the Hold mode. The annunciator “ ” turns on.