4) OPERATION

Introduction

To realize swift simultaneous dual measurements, the meter uses two Analog-to-

Digital Converters (Duo) for its Clamp-on ACA functions (Upper-display readings) as

well as its Rotary-switch functions (Lower-display readings) separately. Clamp-on

ACA functions turn ON whenever the Rotary-switch function is turned ON.

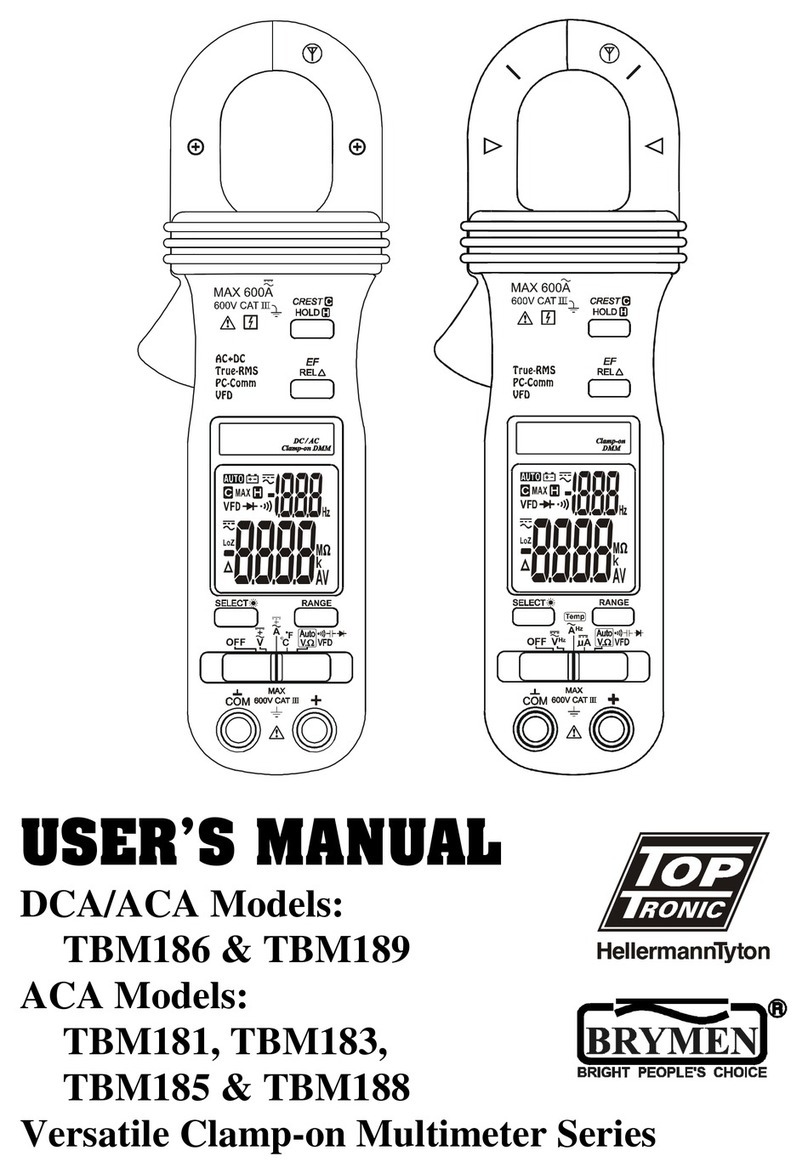

Regular & AmpTipTM Clamp-on ACA functions

Defaults at Regular ACA function where best accuracy is specified at the jaw center

area. Press button momentarily to toggle to AmpTipTM ACA function where best

accuracy is specified near the jaw tip area for low-current small conductors below

10mm in diameter.

WARNING: Do not use the meter to measure currents above the rated frequency

(400Hz). Circulating currents may cause the magnetic circuits of the Jaws reach a

hazardous temperature.

CAUTION: (Application and Removal of the Clamp-on Jaws) Press the jaw trigger and

clamp the jaws around conductor(s) of only one single pole of a circuit for load current

measurements. Make sure the jaws are completely closed, or else it will introduce

measurement errors. Enclosing conductor(s) of more than one pole of a circuit may

result in differential current (like identifying leakage current) measurements. Align the

conductor(s) to the Jaws center indicators (Regular or AmpTip™indicators where

applicable) as much as possible to get the best measuring accuracy. For removal,

press the jaw trigger and remove the jaws from the conductor(s).

CAUTION: Adjacent current-carrying devices such as transformers, motors and

conductor wires may affect measurement accuracy. Keep the jaws away from them as

much as possible to minimize influence.

ACV, Line-Level Hz & EF-Detection (NCV) functions

Inputs, other than that of EF-Detection as described later on, are made via the test

lead terminals COM/+. Defaults at ACV Function. Press SELECT button momentarily

to select ACV, Hz, EF-H & EF-L functions in sequence.

WARNING: Before and after hazardous voltage measurements, test the voltage

function on a known source such as line voltage to determine proper meter functioning.