4421 1999 REV - Page 5

1. GENERAL SAFETY

1.1 Foreword

The purpose of this Service Manual is to provide equipment owners and operators with all information

necessary for the correct use and maintenance of Hydraulic Hammers.

For pile driving to be safely and efficiently undertaken, rig operators need to be experienced in general

techniques and to have good working knowledge of the mechanical features of the Hydraulic Hammer

and ancillary fittings.

We strongly recommend that this publication be read and understood by all staff concerned before the

hammer is operated in the field.

BSP products are engineered for reliable operation and long life in normal conditions of use; reliability

and life can be extended by careful and regular maintenance following the recommendations in the

maintenance section of this manual.

The manual also contains a fully illustrated Parts List and attention of all users is drawn to the preferred

parts ordering procedure.

A. General Orders

When unloading and unpacking the unit use extreme care. For your protection, make thorough

inspection of the unit immediately on delivery. In case of any damage or shortage notify the

transit agent at once and have the delivery carrier make a notation on the freight bill.

B. Safety Precautions

Safety is basically common sense. There are standard safety rules but each situation has its own

peculiarities which cannot always be covered by rules. Therefore, your experience and common

sense will be your best guides to safety. Be ever watchful for safety hazards and correct

deficiencies promptly. Use the following safety precautions as a general guide so safe

operations:

- Never adjust or repair the unit while it is in operation.

-Remove all tools and electrical cords before starting.

For safety information on the use and handling of diesel fuel and hydraulic mineral oil refer to the

information in the operating manual for the Hydraulic Power Pack

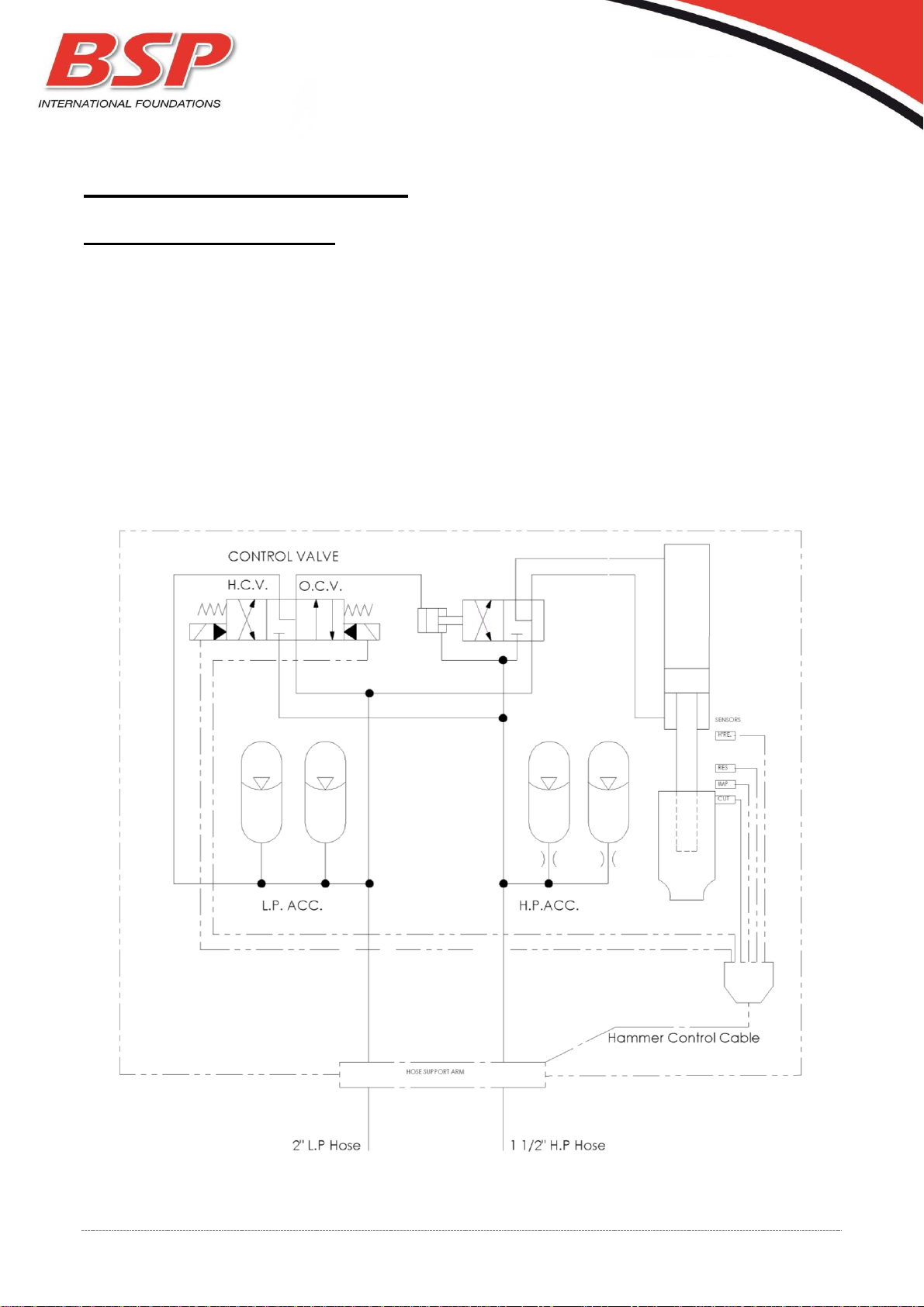

WARNING –The hydraulic system includes nitrogen gas charged accumulators.

Before servicing the hydraulic system, ensure that any retained hydraulic pressure is allowed to

dissipate,

Accumulators are subject to inspection in use according to applicable national regulations

ALL APPLICABLE SAFETY PRECAUTIONS AND RELEVANT SAFETY LEGISLATION SHOULD BE

OBSERVED WHEN OPERATING AND USING HYDRAULIC HAMMERS.

1.2 Safety at Work

NOISE - The use of all types of pile driving equipment will produce noise to varying degrees, which can

be injurious to health.

EAR PROTECTORS - Must be used at all time when in the vicinity of any pile driving operation.

PROTECTIVE CLOTHING - Safety helmets must be worn at all times on construction sites. It is also

recommended that safety boots, safety glasses and fluorescent safety jackets are worn. Life jackets

should be worn in marine sites