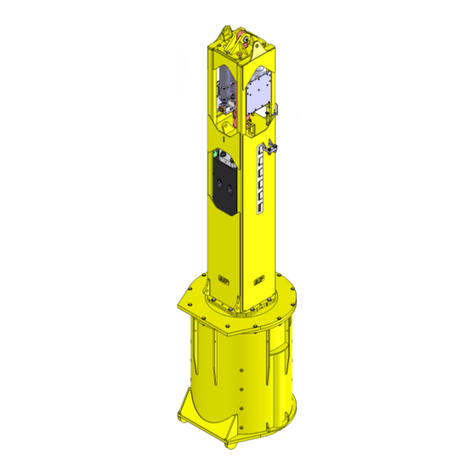

LIGATURE RESISTANT SENSOR FAUCET #SF390

Patent # US D635,386

INSTALLATION, MAINTENANCE & OPERATION INSTRUCTIONS

SENSORFLO® Battery or A/C Powered

Our new Ligature Resistant Sensor Faucet (version 2.0) is the second sensor faucet designed and developed by BSP in conjunction with the

Speakman Company.Its patented design provides for a ligature resistant sink faucet that will mount to existing or new lavatories. Having an

identical external profile to the previous model,the faucet's internal components have been upgraded for improved performance.Its unique

features – such as updated operating mechanisms (Electronic module, Solenoid and Power Pack which are readily serviceable from under the

counter), standard in-line Filters,and new Sensor Module design incorporated into solid zinc chrome plated Faucet body – make it ideal for patient

rooms or public areas that need ligature resistant products.

Speakman/Behavioral Safety Products SENSORFLO® Ligature Resistant Faucet comes standard with six batteries or with an optionalA/C Adapter.

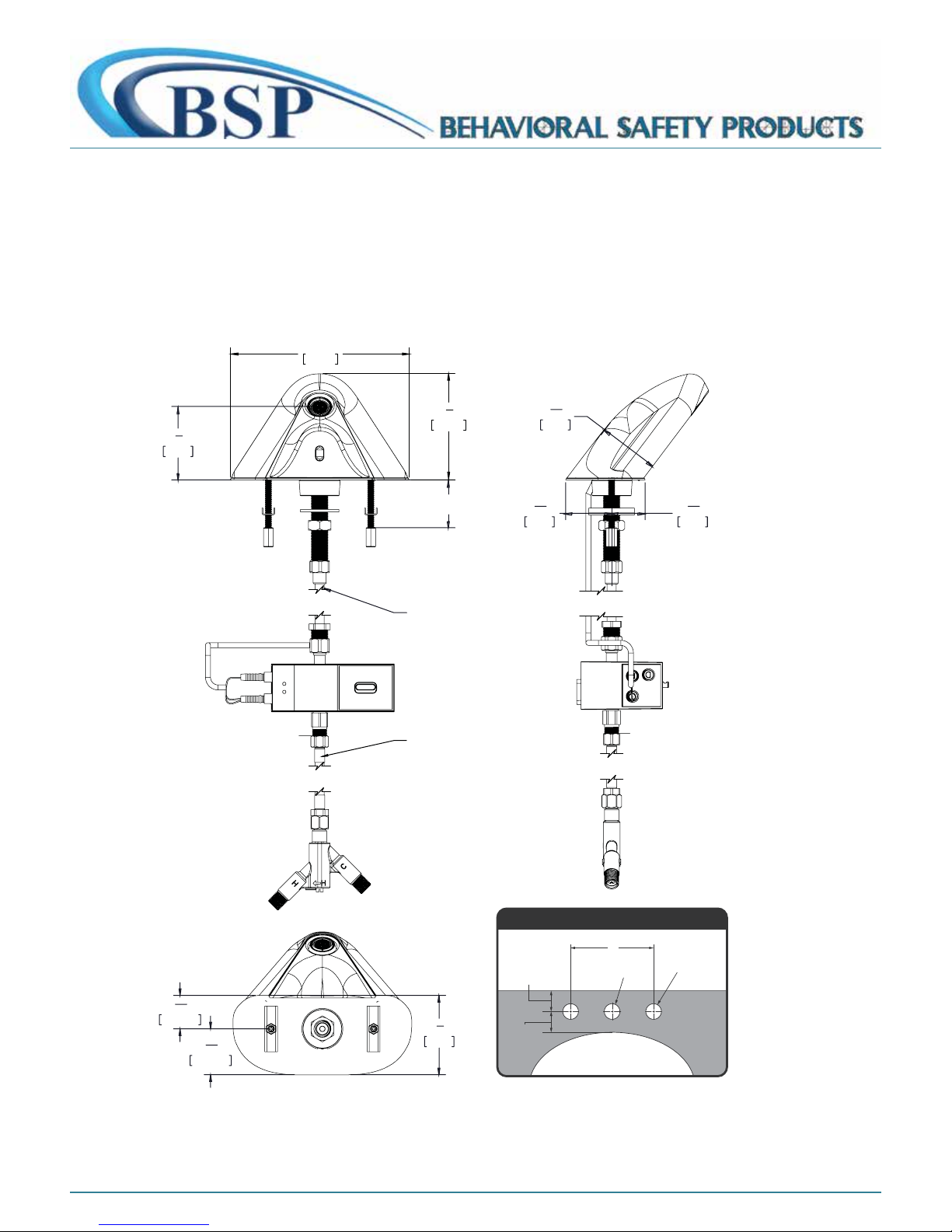

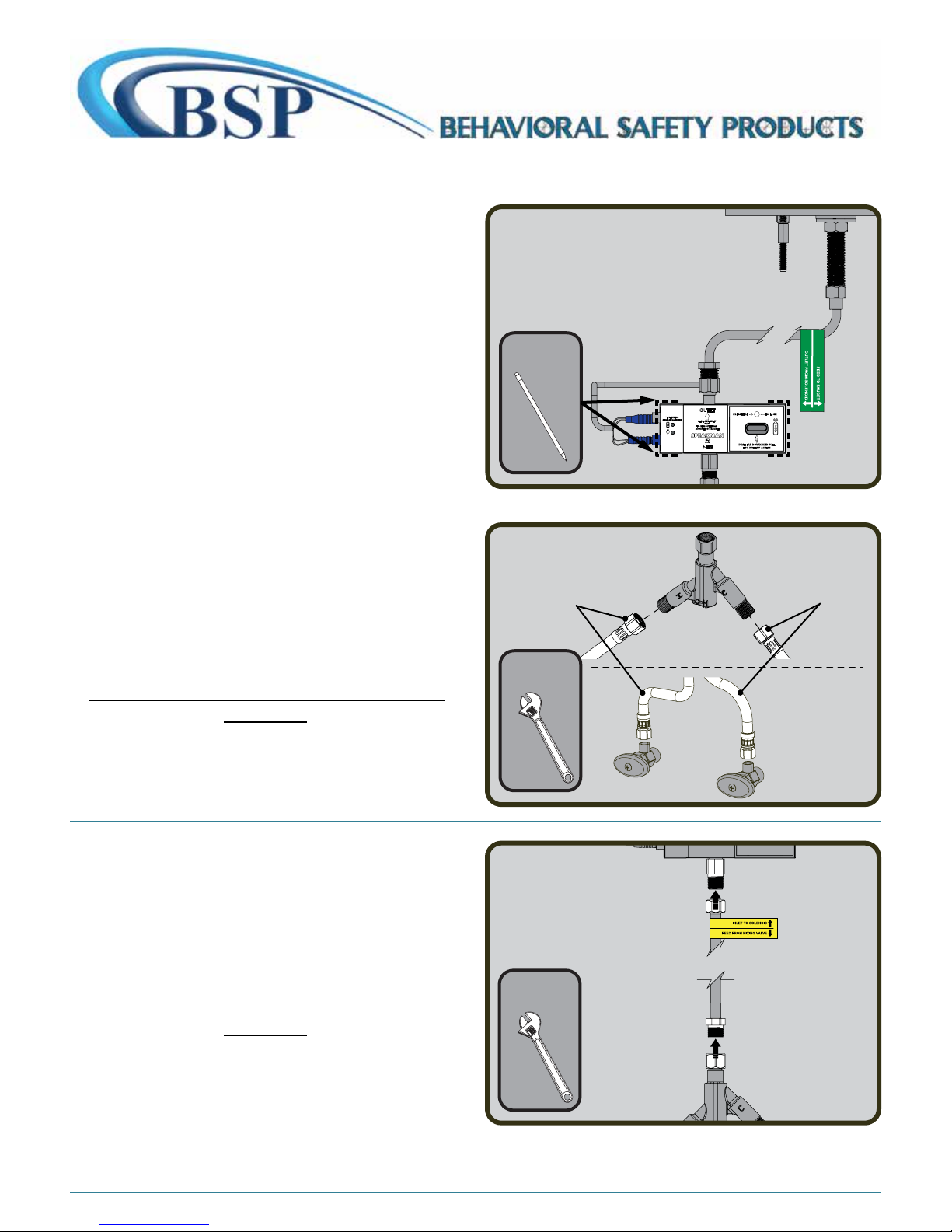

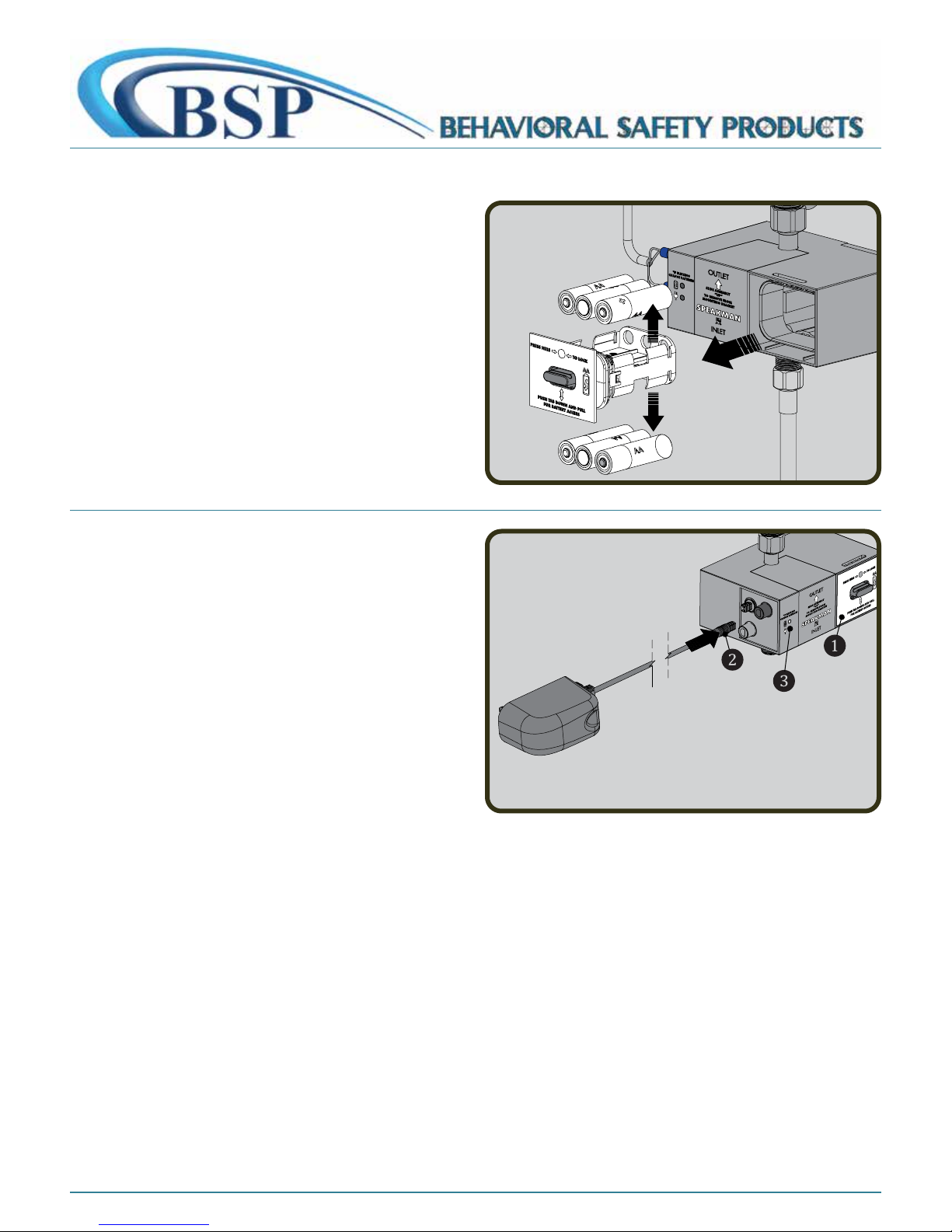

Inside the solid zinc body of the Faucet resides the new Laser Sensor Module.The Solenoid and the Power Supply (Batteries orAC/DC Adapter) are

located under the sink with easy accessibility.

The Solenoid Module is powered by six 1.5v standardAA batteries or optionalA/C Adapter with water-resistant connectors.There are 2 low battery

indicator lights. One located on the Sensor on the Faucet body and the other located on the Solenoid box.When the low battery light on the Sensor

blinks,it indicates the battery power is low.When the low battery light on the Solenoid is blinking,the Solenoid will stop functioning and the

batteries need to be replaced immediately.

Speakman/Behavioral Safety Products SENSORFLO® Faucets are thoughtfully designed and engineered in accordance with the highest quality and

performance standards.The Faucet requires no handles to turn,lift or push for water flow.Built in vandal-resistant circuitry shuts off the water after

continuous flow of approximately 60 seconds.Faucet will resume normal operation after the object causing activation is removed and then waiting

60 seconds.

Water-conserving vandal-resistant recessed Laminar Flow Outlet reduces water flow to 1.2GPM / 4.5 L/min to meet requirements of ASME

A112.18.1/CSA B125.1 for flow rates.There is a water Filter on the Solenoid that is readily accessible for maintenance purposes.

The Faucet is produced with low-lead materials and is designed to meet National and California maximum lead content standards.

SPECIFICATIONS

•This product meets: CAAB1953,NSF 372,UPC, ASME A112.18.1/CSAB125.1,ADA

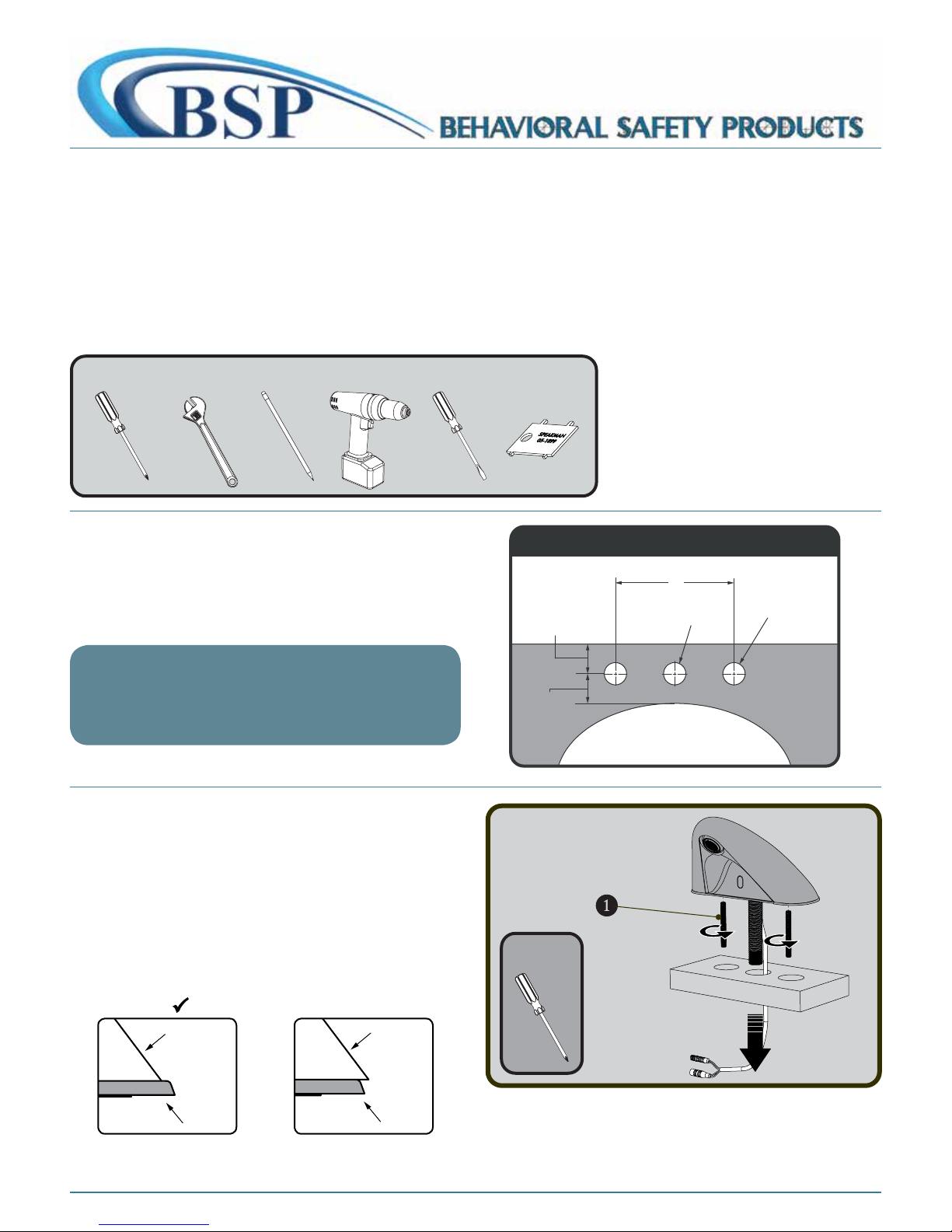

•Inlet Supply: 3/8” compression with male threads for already mixed Cold and Hot Water

•Flow Rate: 1.2 GPM / 4.5 L/min

•Operating static water pressure of 20psi to 80psi

•Zinc Chrome-Plated Finish

STANDARD OPTIONS (See accessories on BSP website)

LF — Laminar Flow 1.2 GPM Flow Control A/C Adapter Kit (RPG76-107259)

T —Tee with checks TMV — UCThermostatic Lead-FreeValve with check valves (SF372)

UCM — Under Counter Mixer 8’’ Cover Plate (SF373) — Converts 8” Centerset Sink to 4” O.C.

Battery Pack — includes six 1.5v AA batteries

706-705-1500

besafepro.com

CONTINUED