BST BS1801 User manual

3 1/2 Digits Unbeatable Best Buy Multimeters with All-Ranges Protection

OPERATION MANUAL

1. SAFETY RULES

This meter is designed and tested in accordance with EN publication 61010-1, pollution

degree II and installation category (overvoltage category) II 600V.

This meter has been tested according to the following EC Directives

♦89/336/EEC Electromagnetic Compatibility, EN61326

♦73/23/EEC Product safety law of Low Voltage Directive, EN61010-1

This meter is designed to be indoor use at temperature 5°C to 40°C and altitude up to

2,000m.

To ensure that the meter is used safely, follow all safety and operating instructions in

this operation manual. If the meter is not used as described in this operation manual,

the safety features of this meter might be impaired.

2. INTERNATIONAL SYMBOLS

Important information

Diode

see manual

Continuity

AC

Ground

DC

Double insulation

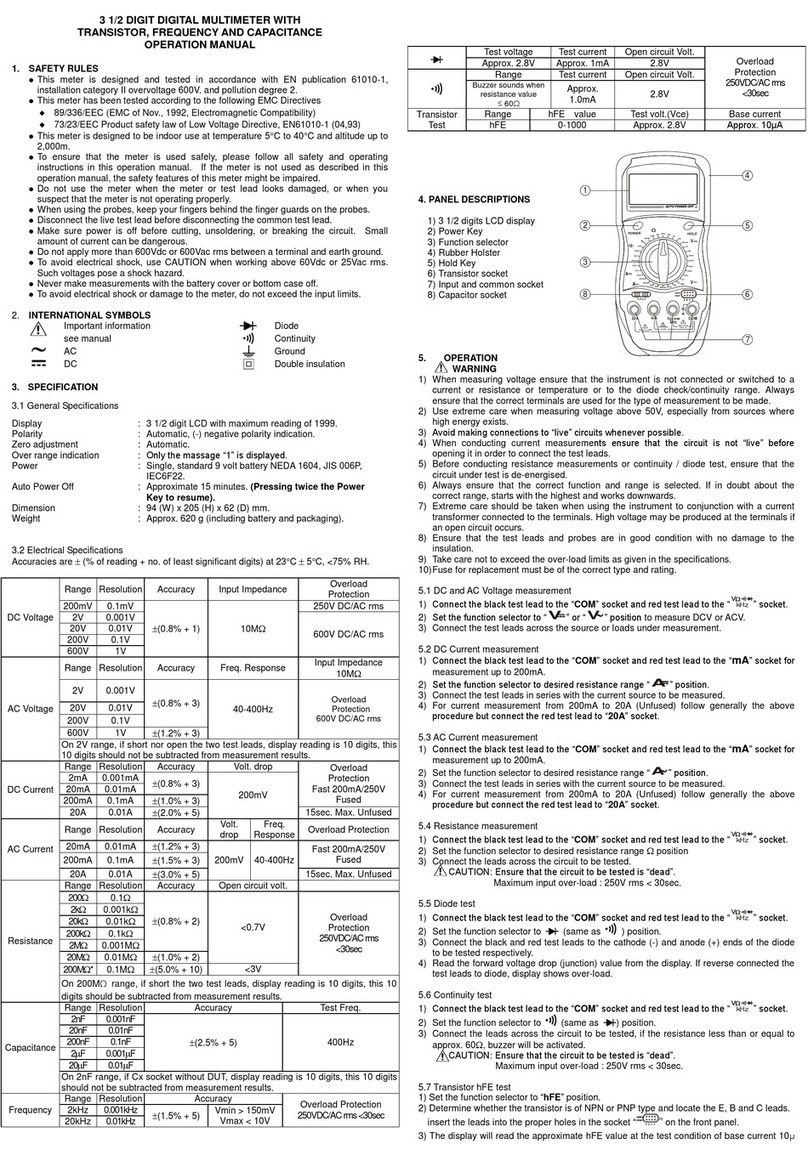

3. SPECIFICATIONS

3.1 General Specifications

Display

:

3 1/2 digit LCD with max. reading of 1999.

Polarity

:

Automatic, (-) negative polarity indication.

Zero adjustment

:

Automatic.

Over range indication

:

Only the MSD “1” is displayed.

Power

:

1.5V AAA battery x 3

Dimension

:

85 (W) x 155 (H) x 40 (D) mm.

Net Weight

:

Approx. 250g. (Including battery).

3.2 Electrical Specifications

Accuracies are ±(% of reading + number of least significant digits) at 23°C ±5°C, <75% RH.

DC Voltage

Range Resolution Accuracy

Input

Impedance

Overload

Protection

200mV

0.1mV

±(1.0%+3) 10MΩ

600V DC/ACrms

2V

1mV

20V

0.01V

200V

0.1V

600V

1V

AC Voltage

Range Resolution Accuracy

Frequency

(Hz)

Overload

Protection

200V

0.1V

±(1.2%+3d) 40~400 600V DC/ACrms

600V

1V

DC Current

Range Resolution Accuracy

Overload

Protection

20mA

0.01mA

±(1.2%+3d) 250V DC/ACrms

200mA

0.1mA

10A*

0.1A

±(5.0%+3d)

Resistance

Range Resolution Accuracy

Open circuit

voltage

Overload

Protection

200Ω

0.1Ω

±(1.2%+3d) <1.0V 250V DC/AC rms

<30 sec.

2kΩ

0.001kΩ

20kΩ

0.01kΩ

200kΩ

0.1kΩ

2MΩ

0.001MΩ

Capacitance

(BS1902/03)

Range Resolution Accuracy

Test

Volt/Freq

Overload Protection

20µF

0.01µF

±(2.5% + 3d) <3V/2.5Hz

250V DC/AC rms

<30 sec

200µF

0.1µF

Temperature

(BS1903)

Range

Resolution

Accuracy

Overload Protection

-20°C to

+400°C

1°C ±(2.5% + 4°C)

250V DC/AC rms <30 sec.

Diode Test

Test Voltage

Test Current

Overload Protection

<3V Approx. 1.6mA

250V DC/AC rms

<30 sec.

Continuity

Test

Test range

Open circuit

Voltage

Overload

protection

Buzzer sounds when

resistance value

<30Ω

<3V 250V DC/AC rms

<30 sec.

Transistor Test

(NPN-PNP)

(BS1901/02/03)

range hFE Value

Overload

protection

hFE 0 – 1000

250V DC/AC rms

<30 sec.

Phase Sequence

Indication

Range

Phase Sequence Indication

380ACV ±10%

Correct Phase Sequence

– Phase Sequence Light “ON”

Live Wire

Verification Voltage

Tested Voltage Range

100~250V

Battery Test

(BS 1901)

Range

Load Resistance

Overload Protection

1.5V load

150Ω

250V DC/AC rms

<30 sec.

12V load

900Ω

Square

Waveform Output

(BS 1901W)

Output Voltage

Frequency

Wave Form

Overload Protection

Approx. 3V 50Hz

Square

Wave

250V DC/AC rms

<30 sec.

* for BS1903 only, use 10A fused current adaptor at 200mV range

4. PANEL DESCRIPTIONS

1. Live wire verification indication light

(BS1901/01W)

2. LCD display

3. Transistor testing socket

(BS1901/02/03); Battery test key

(BS1901W)

4. Multifunction selector

5. HOLD key / Battery test key

6. Phase verification indication light

7. Input terminal

5. OPERATION

!

WARNING

1) When measuring voltage ensure that the instrument is not connected or switched to a

current or resistance, or battery test, or diode/ continuity check range. Always ensure that

the correct terminals are used for the type of measurement to be made.

2) Use extreme care when measuring voltage above 50V, especially from sources where

high energy exists.

3) Avoid making connections to “live” circuits whenever possible.

4) When performing current measurements ensure that the circuit is not “live” before opening

it in order to connect the test leads.

5) Before performing resistance/capacitance measurements or diode test, ensure that the

circuit under test is de-energised.

6) Always ensure that the correct function and range is selected. If in doubt about the correct

range, start with the highest and work downwards.

7) Extreme care should be taken when using the instrument to conjunction with a current

transformer connected to the terminals. High voltage may be produced at the terminals if

an open circuit occurs.

8) Ensure that the test leads and prods are in good condition with no damage to the

insulation.

9) Take care not to exceed the overload limits as given in the specifications.

5.1 DC and AC voltage measurement

1. Connect the black test lead to the “COM” terminal and red test lead to the “V” terminal.

2. Set the multifunction selector to desired DC V or AC V position and connect the test leads

across the source or load under measurement.

5.2 DC current measurement

1. Connect the black test lead to the “COM” terminal and red test lead to the “mA” terminal

for measurement up to 200mA.

2. Set the multifunction selector to desired current range position.

3. Connect the test leads in series with the current source to be measured.

4. When the tested current is above 100mA, the input voltage drop might above 1V; hence,

the test duration cannot exceed 15 seconds!

!

CAUTION: Max. input overload: 250V rms < 20sec.

5.3 Resistance measurement

1. Connect the black test lead to the “COM” terminal and red test lead to the “Ω” terminal.

2. Set the multifunction selector to desired resistance (Ω) range position.

3. Connect the test leads across the circuit to be tested.

!

CAUTION: Ensure that the circuit to be tested is “dead”.

Max. input overload : 250V rms < 20sec.

5.4 Capacitance Measurement (BS1902/03)

1. Connect the black test lead to the “COM” terminal and red test lead to the “ ” terminal.

2. Set the multifunction selector to desired Capacitance (C) range position.

3. Connect the test leads across the capacitance to be tested.

!

CAUTION: Ensure that the capacitance to be tested is discharged.

Max. input overload : 250V rms < 20sec.

5.5 Temperature Measurement (with K-Type

Thermocouple) (BS1903)

1. Connect the K-Type Thermocouple cathode (-) to

the “COM” terminal and the anode (+) to “°C”

terminal.

2. Set the multifunction selector to “°C” range

position.

3. Use the K-Type Thermocouple’ probe contact the

object to be tested (Liquid)

4. If the temperature of the environment is sudden

changed or the resettable fuse is in active mode,

the temperature measurement should continue

after 30 minutes; otherwise, the measurement is

not accurate.

5.6 Diode test

1. Connect the black test lead to the “COM” terminal and red test lead to the “ ” terminal.

2. Set the multifunction selector to (same as ) position.

3. Connect the black and red test leads to the cathode (-) and anode (+) ends of the diode

to be tested respectively.

4. Read the forward voltage drop (junction) value from the display. When the forward biased

is open, the display will shows overload ‘1’ .

!

CAUTION: Max. input overload: 250V rms < 20sec.

5.7 Transistor (NPN/PNP) Test (BS1901/02/03)

1. Set the multifunction selector to hFE position, the meter will display 000

2. Connect the transistor’s pin to the testing socket according to the type of the transistor,

the meter will display transistor’s hFE value, if display abnormal value, it mean wrong

connection is made or the transistor is damage.

!

CAUTION: Max. input overload: 250V rms < 20sec.

!

5.8 Phase Sequence Verification

1. Connect the red test lead to the “c” terminal, black

test lead to “b” terminal and yellow test lead to “a”

terminal

2. Set the multifunction selector to “600V~/abc”

range.

3. Connect yellow/black/red test lead to three-phase

contact point, If the phase sequence indicator

lights on, indicating the connection is in correct

phase sequence.

4. If the phase sequence indicator lights off, please

swap black (b) and red (c) test leads, if the

indicator remains off which means that there is a

missing phase or wrong connection, please use

Live Wire Verification function to verify each phase

again.

5.9 Live Wire Verification (BS1901/1W)

1. Connect the red test lead to the “ ” terminal, black test lead to “COM” terminal and hold

the black test lead (please note: do not touch the test pin and keep your hands away

from the finger guard of the test lead!)

2. Set the multifunction selector to “600V~/abc” range.

3. Use the red test lead to contact the live wire to be tested. When there is a live wire, the

Live Wire Verification lights will turn on.

5.10 Continuity test

1. Connect the black test lead to the “COM” terminal and red test lead to the “ ” terminal.

2. Set the multifunction selector to (same as ) position.

3. Connect the test leads across the circuit to be tested, if the resistance less than 30Ω,

buzzer will be activated.

!

CAUTION: Max. input overload: 250V rms < 20sec.

5.11 Battery test (BS1901/01W)

1. Connect the black test lead to the “COM”

terminal and red test lead to the “batt.”

terminal.

2. Set the multifunction selector to battery

“1.5V or 12V” range

3. To measure the battery voltage without

loading (V1), connect the test leads to

the battery, red test lead to the battery

cathode (+), back test lead to the battery

anode (-). If the display shows ‘−’ which

means the red test lead is connected to

the anode (-).

4. To measure the battery voltage with

loading (V2), press the “HOLD/batt.” key.

The meter presets the internal loading R0

=900Ωfor 12V and R0 =150Ωfor 1.5V.

5. To find the internal impedance (Ri) of the battery, the following formula can be used.

Ri=

Voltage without loading - Voltage with loading

Internal loading

=

(V1 - V2)×R0

V2

For example: V1=1.550V; V2=1.450V; R0=150Ωfor 1.5V battery measurement

5.12 Square waveform output (BS1901W)

1) Connect the black test lead to the “COM” socket and red test lead to the “

mA

” socket.

2) Set the function selector to “

OUT

“position.

3) connect test leads across device under test.

5.13 Measuring AC current with an add-on clamp

(optional)

1. Connect an add-on clamp anode (-) to “COM”

terminal and cathode (+) to terminal

2. Clamp the tested wire with the clamp head and the

AC current value will be shown on the display.

6. MAINTENANCE

CAUTION

BEFORE ATTEMPTING BATTERY REMOVAL OR REPLACEMENT, DISCONNECT

TEST LEADS OR PROBES FROM ANY ENERGISED CIRCUITS TO AVOID SHOCK

HAZARD.

6.1 Fitting and replacing the battery

1. Ensure that the instrument is not connected to any external circuit, set the Multifunction

selector to OFF position and remove the test leads from the terminals.

2. Remove the screw of the battery compartment on the bottom of the back case.

3. Replace the spent battery with the same type and rating.

4. Reinstate the battery compartment, tighten and securing screw.

6.2 Cleaning

Periodically wipe the case with a soft damp cloth and mild household cleanser. Do not use

abrasives or solvents. Ensure that no water gets inside the equipment to prevent possible

shorts and damage.

7. ACCESSORIES

The accessories contained inside the packaging are the following:

Pair of test leads

English instruction manual

3 Phases 3rd test lead with clip

K-Type Thermocouple (for BS1903 only)

10A Current Adaptor (for BS1903 only)

1.5V AAA battery x 3

Certificate of test

Optional: 10A DC current Adaptor 3700- 10A

AC current add-on clamp BS- 06

8. SERVICE

8.1 Warranty Conditions

This meter is guaranteed against any material fault or manufacturer’s defect, in accordance

with the general conditions of sale. During the warranty period (one year), faulty parts may be

replaced, with the manufacturer reserving the right to decide either to repair or replace the

product.

In the event of returning the meter to the after-sales service or to a regional branch, the

outward transport is payable by the customer. The delivery must be agreed in advance with

consignee.

For delivery indicate, by means of an enclosed note, as clear as possible, the reasons for

returning it. Use only the original packing.

Any damage caused by shipment using NOT the original packaging will be charged in any

case to the consignor.

The manufacturer will not be responsible for any damage to persons or things.

The warranty does not apply to the following cases:

Accessories and battery are not included in warranty.

Repairs following unsuitable use of the meter or by combining the latter with incompatible

meter or accessories.

Repairs resulting from incorrect shipping.

Repairs resulting from servicing carried out by a person not approved by the company.

Modifications to the meter without explicit authorisation from our technical department.

Adaptation to a particular application not provided for by the definition of the meter or by

the instruction manual.

The contents of this manual may not be reproduced in any form whatsoever without the

manufacturer’s authorization.

Our products are patented. The logotypes are registered. We reserve the right to

modify specifications and prices as part of technological developments which might

be necessary.

8.2 Service

If the meter should not work properly, before contacting the DEALER OR THE SERVICE

CENTRE, check the battery condition, the test leads, etc., Change them if necessary.

If the meter still does not work, check if your operating procedure agrees with the description

in this manual.

In the event of returning the meter, it must be re-sent to the after-sales service (at address or

to a regional branch), the outward transport is payable by the customer. The delivery must be

agreed in advance with consignee.

For delivery indicate the reasons for returning it. (By means of an enclosed note, as clear as

possible). Use only the original packing.

Any damage caused by delivery with NO original packaging will be charged in any case to the

consignor.

FOR TECHNICAL ASSISTANCE,

PLEASE CONTACT:

Ri=

(1.550 – 1.450)×150

≈10.34Ω

1.450

1901/1901W/1902/1903

REV1/DEC 06

!

Remarks: Due to our policy of continual product development, we reserve the

right to amend the specifications of the mentioned products without notice.

Other BST Multimeter manuals