8

4.0 OPERATIONS

4.1 TO THE NEW OPERATOR OR OWNER

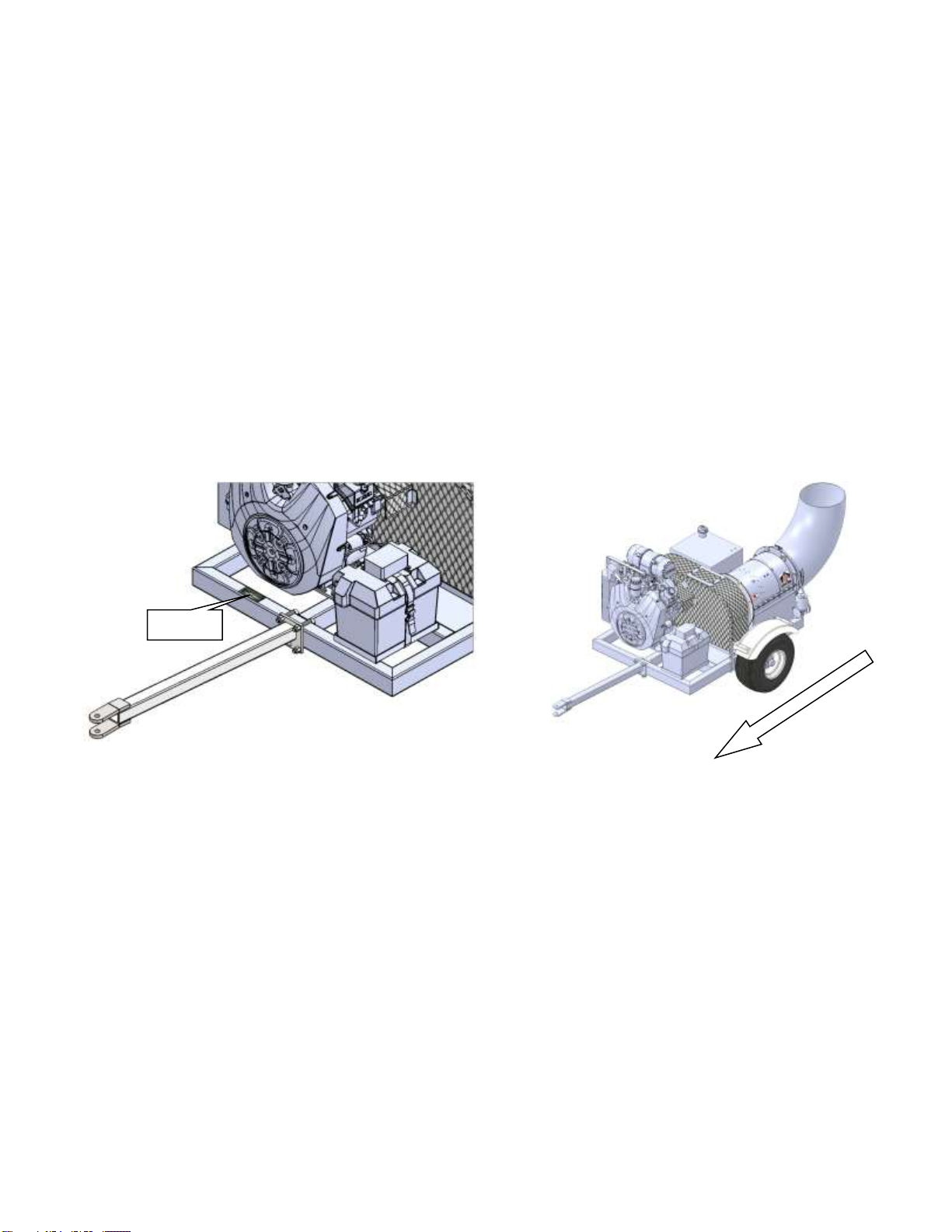

Buffalo Turbine Debris Blowers are designed to quickly and efficiently, blow away leaves, cuttings and other debris. The material is

conveyed on a stream of high volume and velocity of air to remove it from the area of concern. When the material is removed, it gives a

neat, professional look to the working area.

Many of the features incorporated into the machine are the result of suggestions made by customers like you. Read the manual carefully to

learn to operate the machine safely and how to set it to provide maximum efficiency. The manual will take you step-by-step through your

working day. By following the operating instructions in conjunction with a good maintenance program, your Blower will provide many

years of trouble-free service.

Potential Mechanical Hazards while operating your machine:

Never operate the debris blower around others to prevent the possibility of being run over by equipment.

Never ride on your debris blower to prevent the possibility of being thrown off the machine or hurt severely.

Potential Crushing Hazards while operating your machine:

Between Trailer Tongue and mounting hitch on towing vehicle

Between each nozzle

4.2 BREAK-IN

Although there are no operational restrictions on the Blower when it is used for the first time, it is recommended that the

following mechanical items be checked:

A. Operating for first ½ hour

1. Re-torque all wheel bolts, axle nuts and trailer mounting bolts and nuts.

2. Re-torque all other fasteners and hardware.

3. Check set screw (nozzle pulley) to ensure it tightened.

B. Operating for first 5 hours

1. Re-torque all hardware and fasteners.

2. Check set screw (nozzle pulley) to ensure it tightened.

3. Go to the normal servicing and maintenance schedule as defined in the Maintenance Section of the manual.

4.3 PRE-OPERATION CHECKS

Efficient and safe operation of the Buffalo Turbine Blower requires that each operator reads and understands the operating procedures and

all related safety precautions outlined in this section. A pre-operation checklist is provided for the operator. It is important for both personal

safety and maintaining the good mechanical condition of the machine that this checklist is followed.

BATTERY MUST BE CONNECTED BEFORE OPERATION (DISCONNECTED FOR SHIPPING).

Before Operating the Blower and each time thereafter, the following areas should be checked off.

1. For fuel, oil, and operating information of the Kohler Engine, refer to the Manufacturers specs included with this manual.

2. The Model MEGA turf trailer is not designed for highway towing. For highway use or speeds above 15mph (24kph) an optional DOT

approved trailer must be used.

3. Insure the Blower unit is attached to a proper receiver mounted on the towing vehicle. A pin hitch receptacle is standard with the

model MEGA. Attach the MEGA trailer using the proper size hitch pin with a locking presto pin.

4. Make sure all guards and shields are in place, secured and functioning as designed.

5. Check that all clamp bands are secure.

6. Check the belts and pulleys for proper tension and alignment.

Remote Nozzle and Throttle Control

(REFERENCE PAGES 21-27 FOR WIRELESS REMOTE INSTRUCTIONS)

The throttle control adjusts the engine RPM from an idle to maximum RPM and the nozzle control adjusts the rotation of the nozzle

assembly (360 in either direction).