www.bullard.com

Free-Air® Pumps

Instruction Manual

7

Maintaining the Free-Air Pump/Troubleshooting Guide

Maintaining the Free-Air®Pump

Bullard Free-Air pumps consist of an electrically driven air pump with four

carbon vanes. The vanes self-adjust as they wear and should last from 5,000

to 15,000 hours if properly maintained.

For the pump to operate at its optimum performance level, the following

routine maintenance procedures must be performed:

1. REPLACE THE INLET AND OUTLET FILTERS REGULARLY

Dirty filters may inhibit air flow to the respirator(s), and cause the motor to

overload and decrease vane life.

- Replace the Carbofine outlet filter cartridge (Cat. No. S17101) at least once

every 200 running hours or sooner, if necessary.

- Replace the inlet filter (Cat. No. 23611) at least once every 500 operating

hours or sooner, if necessary.

2. FLUSH PUMP IF NECESSARY

Should excessive dirt, sand, foreign particles, moisture or oil be permitted

to enter the pump, the carbon vanes will become sluggish and the pump’s

performance will deteriorate. This will result in decreased outlet pressure or

failure of the pump to operate.

If the pump remains idle in a humid environment for a long period of time,

rust film may build up in the pump’s chamber and rotor slots. This will result

in decreased outlet pressure or a failure to operate at all.

If the above occurs, the pump should be flushed with the following

recommended solvent:

- Loctite Safety Solvent (Cat. No. S17931)

�WARNING

NEVER USE KEROSENE OR OTHER COMBUSTIBLE LIQUIDS OR VAPORS WITH THIS

PUMP. THEIR USE MAY RESULT IN AN EXPLOSION WHICH MAY CAUSE INJURY OR

DEATH.

Directions for Flushing Pump

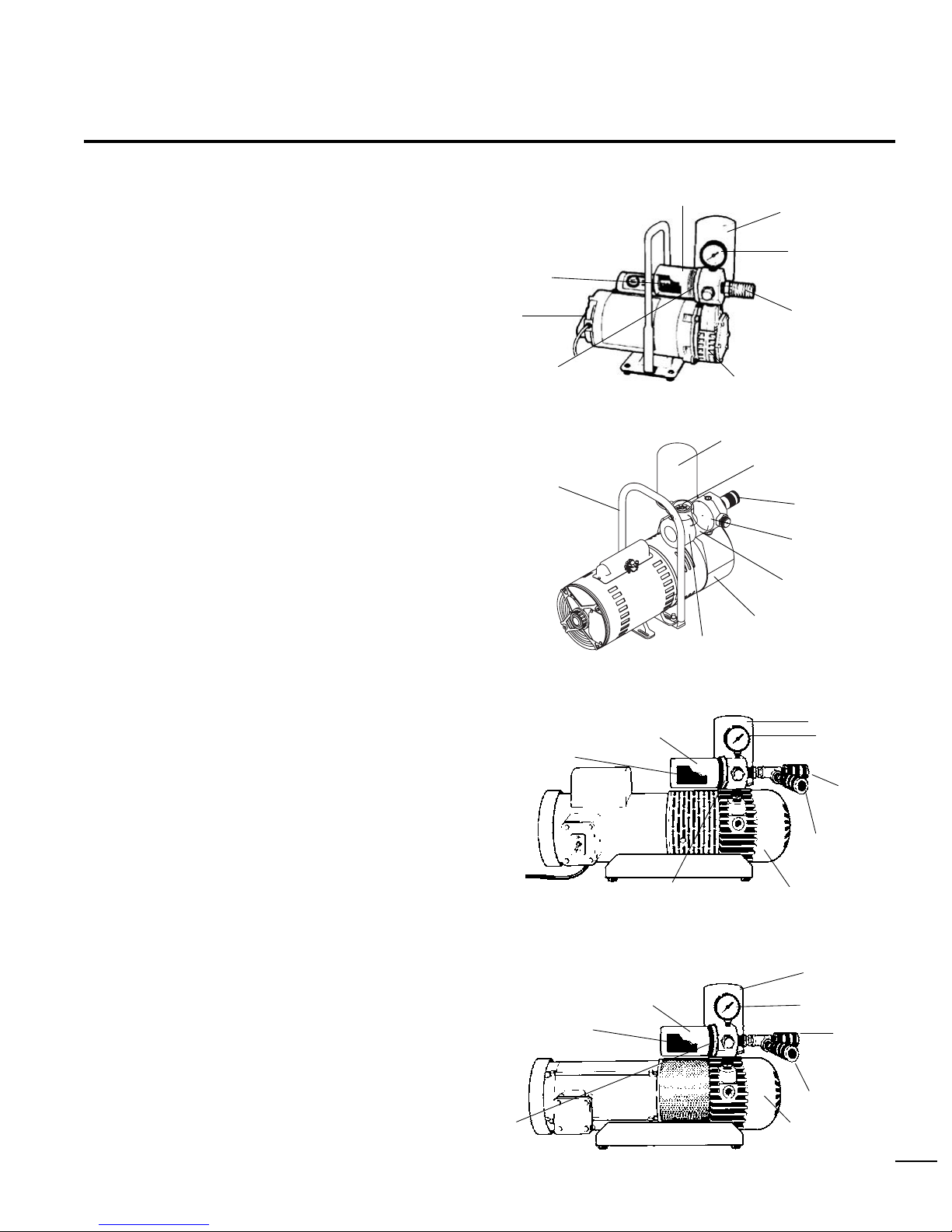

a. Before flushing, disassemble and remove the following parts from the

pump:

- Disconnect the respirator’s air supply hose

- Remove the pump’s inlet filter

- Remove the pump’s outlet filter jar and outlet filter cartridge

b. With the pump running, pour several ounces of approved safety solvent

into the pump’s air inlet port. Repeat the flushing if necessary.

�WARNING

RUN THE PUMP FOR A SUFFICIENT TIME TO PURGE ALL TRACES OF THE SOLVENT

BEFORE REPLACING THE FILTERS, RECONNECTING THE AIR SUPPLY HOSE(S) AND

USING THE RESPIRATOR.

3. IN EVENT OF BROKEN VANES

Should you experience broken vanes in your Free-Air pump, it is important to

thoroughly clean out not only the rotor and drum, but also the inlet and outlet

filters.

Before cleaning

- Disconnect pump from power source

- Disconnect respirator’s air supply hose

- Remove the pump’s inlet filter

- Remove the pump’s outlet filter jar and outlet filter cartridge

- Remove the end plate which covers the rotor and drum

Remove any large pieces of vane which may still be located in the vane slots,

located on the rotor.

Next, tilt pump forward towards the ground (in the direction of the quick-

disconnect coupler), being careful not to impact ground, and allow any unseen

dust and debris to fall out of the pump. Jiggling and shaking to aid removal is

acceptable.

Use a can of compressed air, or a compressed air tool to spray air through

the air inlet port. Do the same in and around the rotor and drum, ideally

while in a forward tilted position to aid in removal. Finally, apply compressed

air to the outlet filter housing.

Repeat steps as necessary, until no further debris is emitted.

After no further debris is present, turn the rotor by hand in a clockwise

direction to ensure that the rotation is smooth, with no audible or felt grinding

or resistance. If grinding or resistance is felt, re-apply compressed air.

4. AVOID RUNNING THE PUMP AT EXCESSIVE PRESSURE

Avoid running the Free Air pump above 15 psig (103 kPa) for any length of

time. Running the pump above 15 psig (103 kPa) could cause motor damage

and will create premature wear of the carbon vanes.

NOTE

NEVER LUBRICATE THIS OIL-LESS PUMP. THE MOTOR BEARINGS

ARE GREASE PACKED AND SEALED. THEY REQUIRE NO FURTHER

LUBRICATION.

Free-Air Pump Trouble Shooting Guide

If your Bullard Free-Air pump is not working satisfactorily, please follow the

trouble shooting steps below:

Initial Checklist

1. You should be using Bullard V20 hose for Free-Air Pumps.

2. If using an extension cord, Bullard recommends 15 amp, 3-wire, 12 AWG

grounded extension cord up to 100 feet. Do not overload the circuit with

additional electrical equipment. The EDP10 requires at least a 7 kw

generator and the EDP16TE requires at least a 12 kw generator.

3. If using a Bullard cool tube, only the Frigtron 2000 is approved for the

EDP30 and ADP20. All other Free-Air Pumps do not support cool tubes.

SYMPTOM: Pump Fails to Start or Hums

1. Turn pump switch off and disconnect from the power source.

2. Check for the correct electrical current as shown on the motor plate and in

the Electric Motor Specification Chart on page 7 of this manual.

3. The pump is equipped with a thermal overload protector that turns the

current off when subjected to electrical overloads. Check to be sure that

the circuit is not overloaded by the pump and other electrical equipment.

4. Check to make sure that the carbon vanes move freely. If stuck to the

housing wall then flush with Loctite Safety Solvent.

5. Wait 15 minutes and restart.