Take note of the resulting color. Future coolant additions can be made by

approximating the color of the mix rather than exact measurement. When properly

mixed the color will be similar to Windex and have a distinct oily feel.

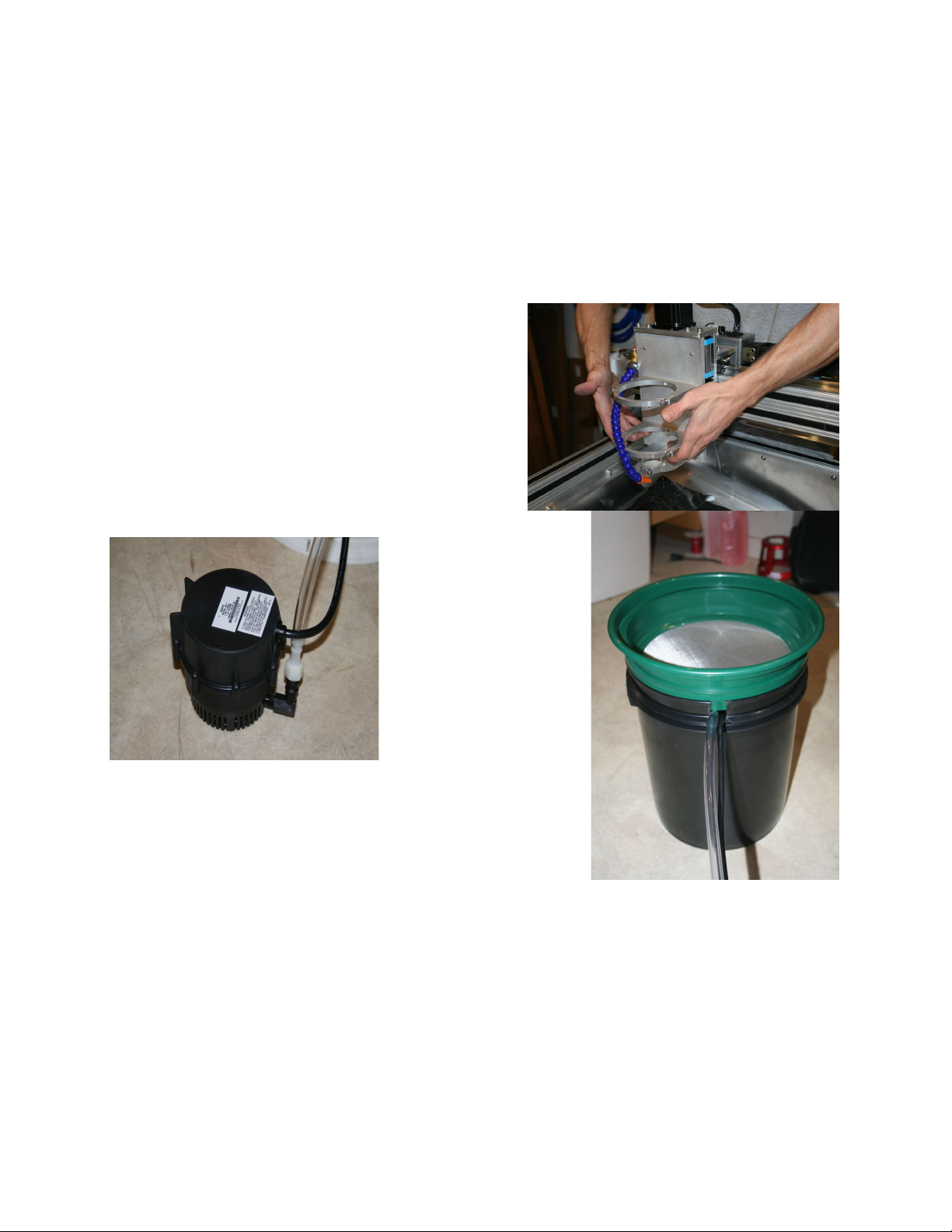

Check the coolant level before use by simply removing the lid and observing the level.

If it is less than about 2/3 full, add a gallon.

During use, if the coolant looks milky in the hose leading up to coolant spout, then the

pump is sucking air. Take care not too add too much coolant during cutting to prevent

overflow when all of the coolant drains into the pail.

The coolant level in the pail should cover the motor at all times for proper motor cooling.

You will find that you will need to add water frequently. It may not be necessary to add

Koolmist every time, but if the color becomes less blue, then the mixture is too lean, and

it loses lubrication capability.

The cutting process will create a sludge of very fine metal particles. Plan to replace the

coolant and clean the pail every 3-4 months or sooner.

Plan to clean the chips out of the drain pan every day. The chips may be scraped uphill

in the drain pan to facilitate draining.

.

17.You will find the 2 pieces of the flow director as flat pieces of aluminum shipped

inside the coolant pail. Fit the 2 pieces together and Install it in the drain hole. Its

purpose is to prevent coolant splashing beside the screen in the pail when a large

volume of coolant is poured in the pan. It is shown assembled and installed to the

right.

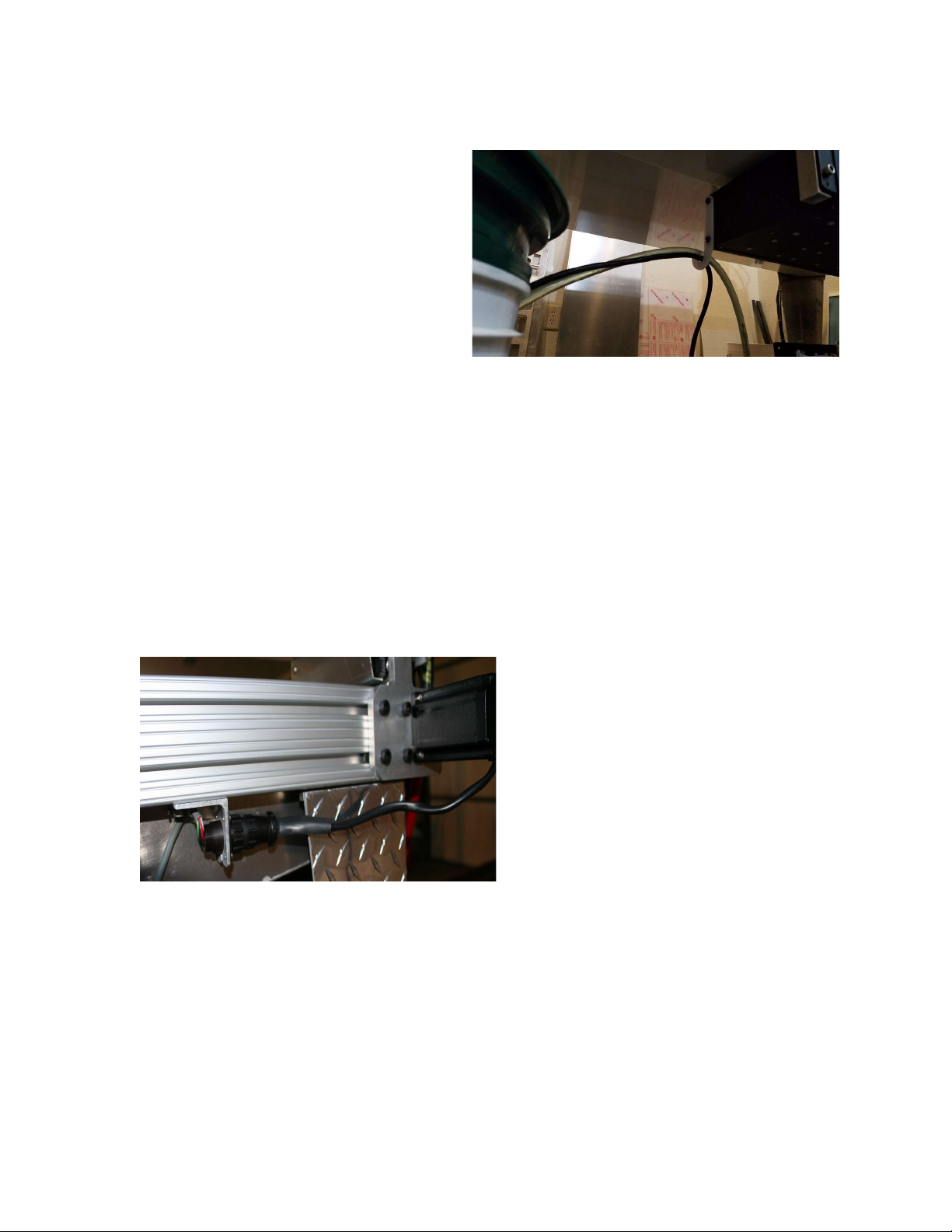

18.The controller mount bars (shipped in the tool box) are mounted to the front of the

drain pan. Supplied with the controller mount bars are 8 each 6x25 mm socket head

screws. Liberally apply silicone seal under the head of 4 of the 6mm socket head

screws. Loosely install the controller mount arms

to the drain pan with these screws. Attach the SC3

controller to the arms with the remaining 4

6x25mm screws. Line up the arms and tighten the

screws. There is a bag packaged with the

controller that includes the laser key and a 2 pin

shorting plug. The 2 pin shorting plug

MUST be installed on the rear of the controller in order for the

controller to turn on. The plug is provisions for a customer supplied safety

curtain.