Match Tubing Sizes with the Enclosure Sizing

8’x10’x5’

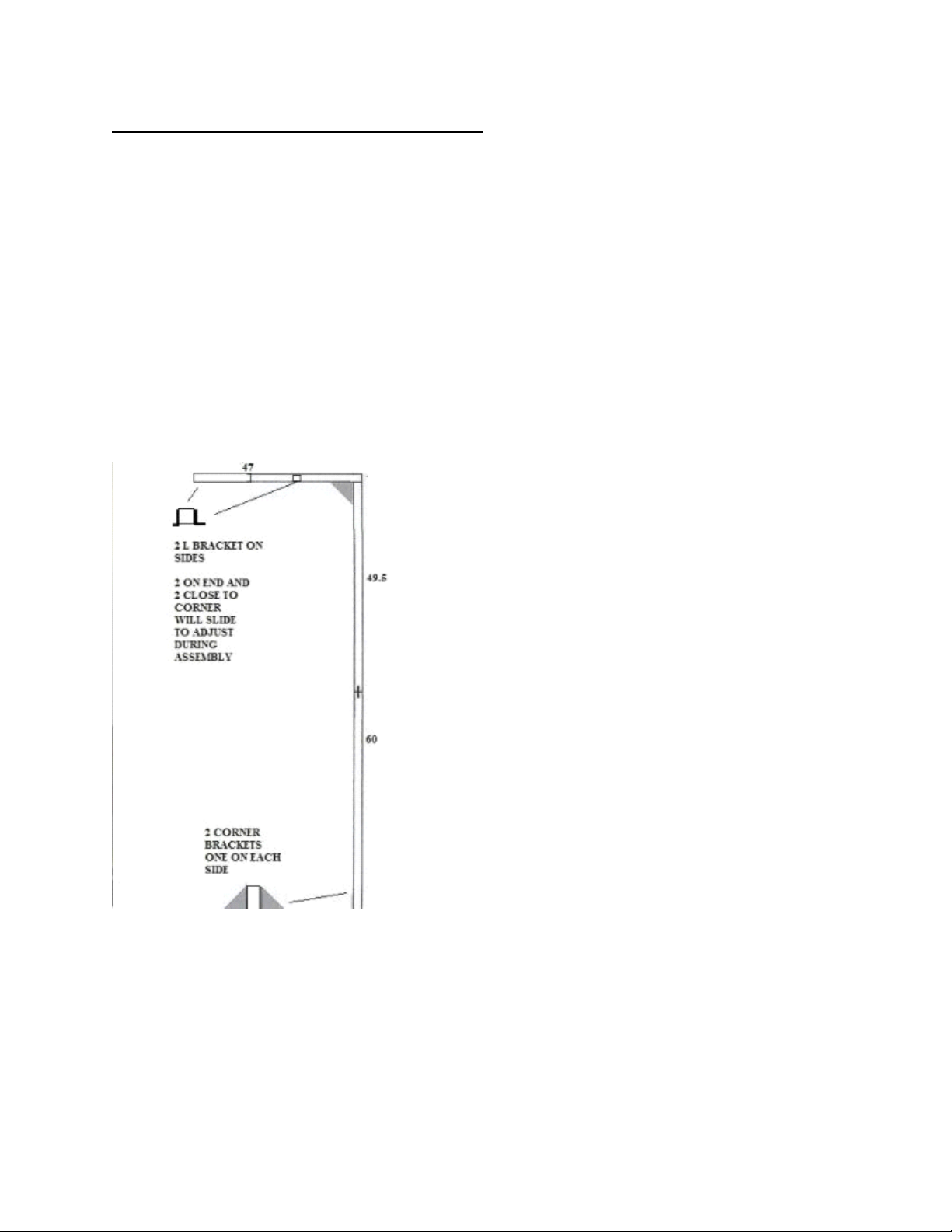

2 A-B (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2- A-B 48”+48”

2 A-C (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2- A-C 48”+46 1/2”

3 E-E (1 1/2” TUBING SPLICERS ON 3 SIDES , SIDES AND TOP) 3-60”+60”

2 D 68" (1 1/2” TUBING) 2-68”

2 H 60" (1 1/2” TUBING) 2-60”

9'x12'x5'

2 A-B (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2-A-B 60”+48”

2 A-C (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2- A-C 60”+ 46 1/2”

3 E-E (1 1/2” TUBING SPLICERS ON 3 SIDES , SIDES AND TOP) 3- 72”+72”

2 D 68" (1 1/2” TUBING) 2-68”

2 H 60" (1 1/2” TUBING) 2-60”

9'x14'x5'

2 A-B (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2-A-B 60”+48”

2 A-C (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2- A-C 60”+ 46 ½

3 E-E (1 1/2” TUBING SPLICERS ON 3 SIDES , SIDES AND TOP) 3- 60”+ 60"+48"

2 D 68" (1 1/2” TUBING) 2-68”

2 H 60" (1 1/2” TUBING) 2-60”

9'x15'x5'

2 A-B (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2-A-B 60”+48”

2 A-C (1 1/2” TUBING WITH SPLICER ON OPPOSITE SIDES) 2- A-C 60”+ 46 1/2”

3 E-E (1 1/2” TUBING SPLICERS ON 3 SIDES , SIDES AND TOP) 3-60”+ 60”+ 60”

2 D 68" (1 1/2” TUBING) 2-68”

2 H 60" (1 1/2” TUBING) 2-60”