tel. 816-878-6675 burger & brown engineering

fax 816-878-6683 2

Fixed Bar Installation

The following installation instructions are for reference

only. Installation may vary depending on knock-out

arrangement and pneumatic connection location.

1. Install studs into the mold ejector plate. See figure 3. If

the press has a non-adjustable ejector home position,

insert washers under the stud so the shoulder is flush

with the back face of the mold clamp plate. Use a thread-

locking compound where threaded parts connect to

prevent movement during use.

2. Insert the ejector bar and coupler through the platen and

into the press ejector plate. For presses with non-

adjustable ejector home position, install the coupler (in

the open position) so it extends 1/8"(3.18mm) past the

platen surface. The coupler, in the closed position, will

be flush with the platen surface. See figure 4.

3. Clamp A side mold plate to the machine, making sure the

mold is positioned squarely.

4. Install washer, nut and pneumatic connector per figure 5.

Use a thread-locking compound to prevent movement

during use.

5. If using the manifold accessory, mount the manifold and

tubing so they do not interfere with moving parts.

6. Connect shop air lines to the FASTIE couplers. Couplers

must be in the open position (see figure1) before

connection to male studs, otherwise coupler damage

will occur.

7. Move the platen forward so the coupler and stud are

connected.

8. Clamp the B side of the mold to the platen. Tighten the

nut to the press ejector plate after Fastie components are

coupled. This assures alignment of the FasTie system.

9. Follow “Test Installation” procedure on the next page.

SpeedBar™ Adjustable Knock-Out

Bar Installation

The following installation instructions are for reference

only. Installation may vary depending on knock-out

arrangement and pneumatic connection location.

1. Install studs into the mold ejector plate. See figure 3. Use

athread-locking compound where threaded parts connect

to prevent movement during use.

2. Shorten the SpeedBar to slightly shorter than the

working length to avoid interference during mold setup.

3. Insert the SpeedBar and coupler through the platen and

into the press ejector plate. The coupler must be in the

open position. See figure 1.

4. Clamp A side mold plate to the machine, making sure the

mold is positioned squarely.

5. Install washer, nut and pneumatic connector per figure 5.

Use a thread-locking compound to prevent movement

during use.

6. If using the manifold accessory,mount the manifold and

tubing so they do not interfere with moving parts.

7. Connect shop air lines to the FASTIE couplers. Couplers

must be in the open position (see figure 1) before

connection to male studs, otherwise coupler damage

will occur.

8. Move the platen forward so it just meets the ejector

housing.

9. Clamp the B side of the mold to the platen. With your

hand, push the SpeedBar locking sleeve toward the mold

and turn it clockwise (looking from the nut end) to

lengthen until the female coupler snaps shut, then

release.

10. Tighten the nut to the press ejector plate.

11. Follow “Test Installation” procedure on the next page.

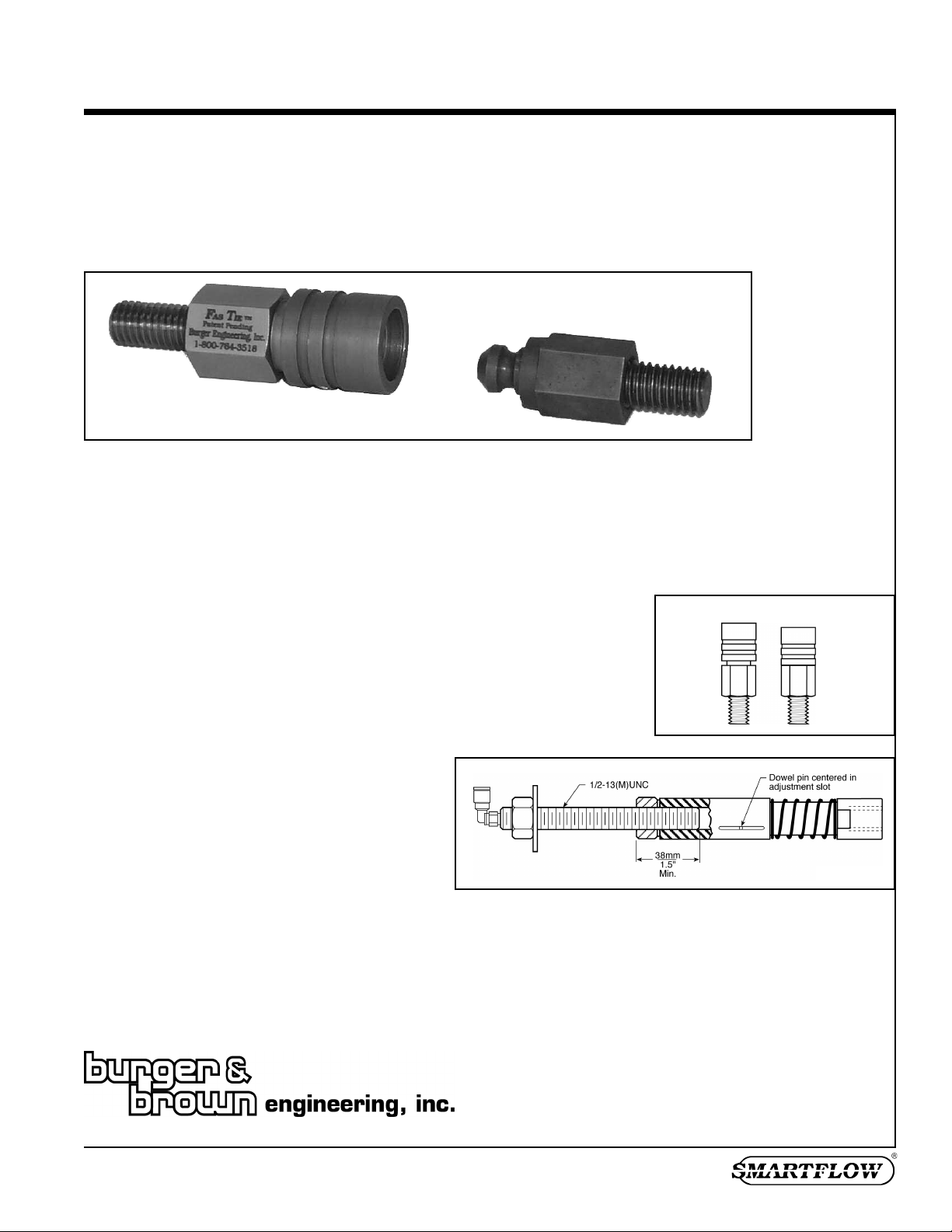

FasTie™ Quick-Connect Knock-Out System and

SpeedBar™ Adjustable Knock-Out Bar

figure 3

figure 4 figure 5