10

3. Light the firelighters and close the door until the notch in the end of

the latch is engaged with the pin on the body of the stove. This will

hold the door open ajar and allow the correct air flow for the first

part of the lighting process. As the kindling catches and starts

burning vigorously, gradually close the door latch fully

4. If the fire stays alight, leave the door shut. If the fire starts to die

down and the embers are dull, open the door and place into the

latch as described in 3 above. Leave it like this for a few minutes to

allow the fire to get hotter. Then shut the door completely.

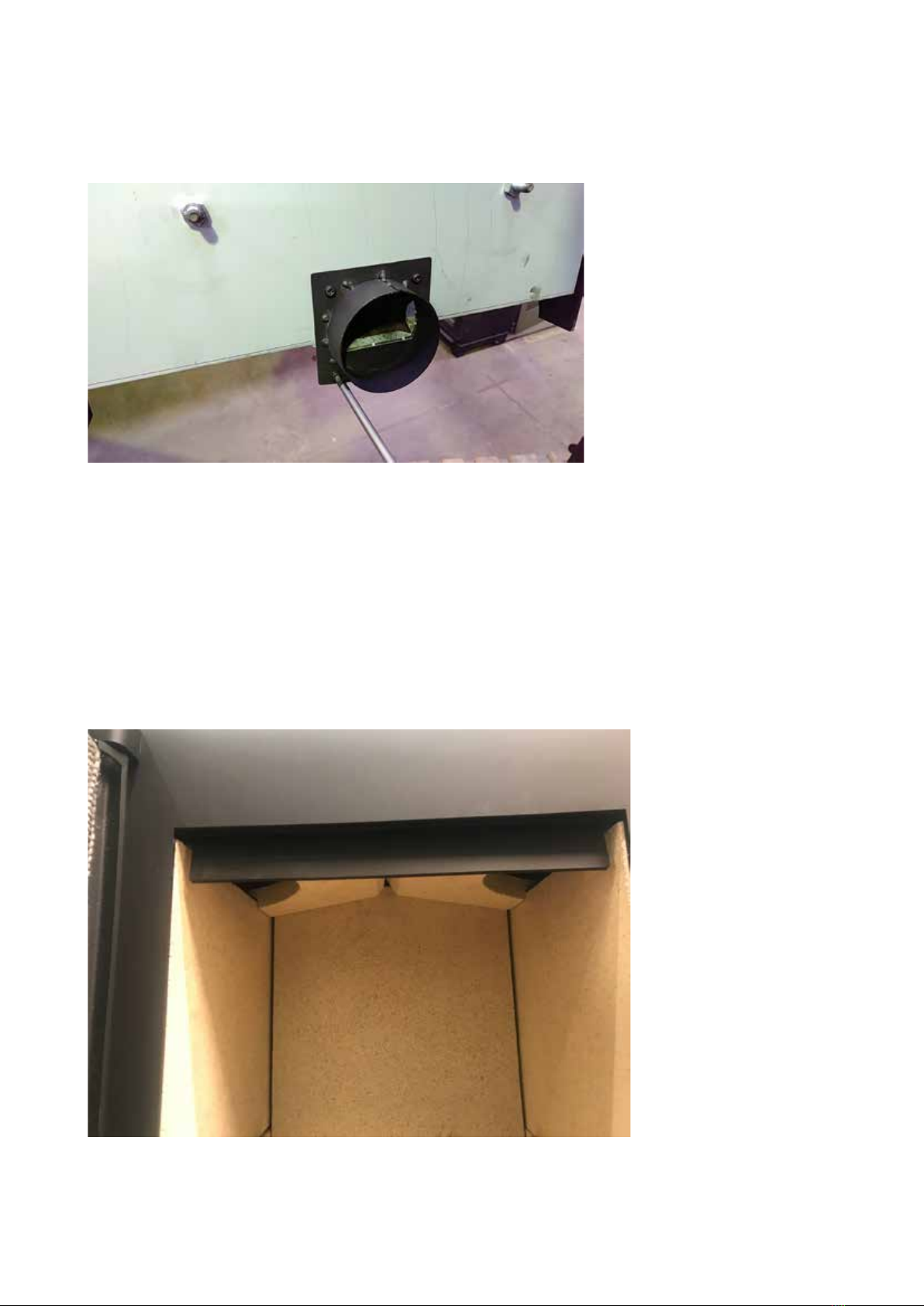

5. When the fuel bed has largely burnt down, refuel by adding

approximately 750g of wood every 30 minutes or so. The logs

should be loaded onto the ember bed in a manner which ensures

they do not fall forwards against the door. If a log does happen to

fall against the door do not open the door to reposition, the log

could roll out, instead allow the fire to burn down and let it go out.

The maximum log size is approximately 400mm x 150mm. The

number of logs will vary depending on their size. Never over fill the

stove because burning wood may spill out of the stove which is

dangerous. Shut the door fully.

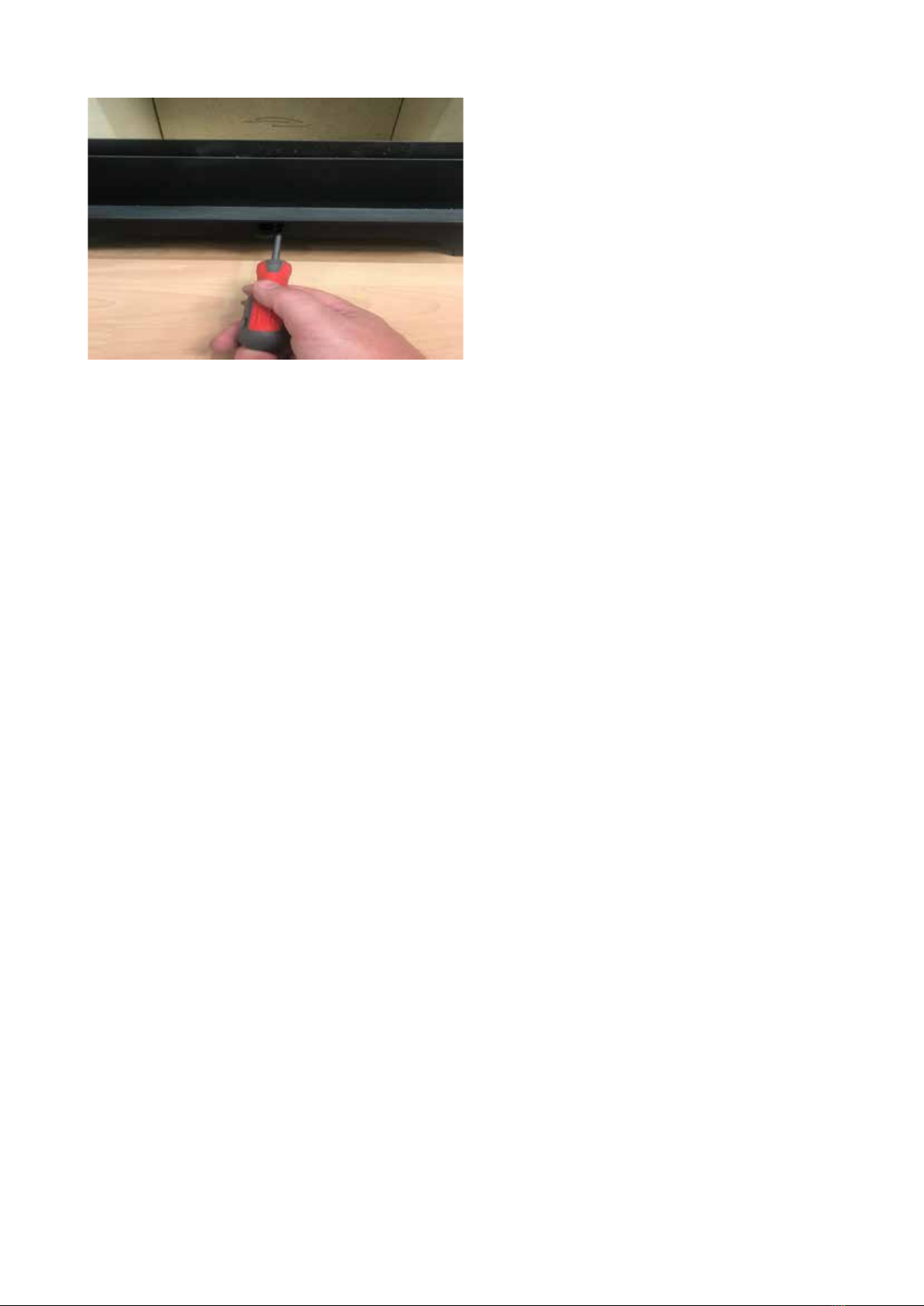

6. You can regulate how vigorously the fire burns by pushing in or

pulling out the lever. The air should NOT be shut right down

allowing the stove to smoulder, to prevent this there is a smoke

control screw which your fitter should have set (see page 10-11).

7. Allow the logs to burn down until you just have red embers and

little or no flame. When adding new fuel, have the logs ready, and

have the door open for as little time as possible to retain the heat in

the stove. Open the door slowly then add 1-3 logs. If the logs have

not shown any signs of lighting after a minute, open the air control

fully and allow the logs to catch light. Repeat until you no longer

wish to run the stove, then allow the fuel to burn out. Do not try to