5

A. Design and install system piping to prevent oxygen

contamination of appliance water and frequent water

additions.

1. There are many possible causes of oxygen contami-

nation such as:

a. Addition of excessive make-up water as a result

of system leaks.

b. Absorption through open tanks and fittings.

c. Oxygen permeable materials in the distribution

system.

2. In order to insure long product life, oxygen sources

must be eliminated. This can be accomplished by

taking the following measures:

a. Repairing system leaks to eliminate the need for

addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fittings which

allow oxygen absorption.

d. Use of non-permeable materials in the distribu-

tion system.

e. Use properly designed and operating air

elimination devices in water piping.

B. Connect system supply and return piping to appliance.

The supply piping should be connected to the front

connection of the coil to ensure proper venting. See

Figures 1, 3 and 4. Also consult I=B=R Installation and

PipingGuides.Maintainminimum½inchclearancefrom

hot water piping to combustible materials.

IV. Water Piping

C. Units must be assured an adequate supply of hot or

chilled water by proper sizing of the distribution

system, circulator and balancing provisions.

D. Supply and return piping may penetrate unit from the

bottom, rear or side (recessed units only). See Figure 2.

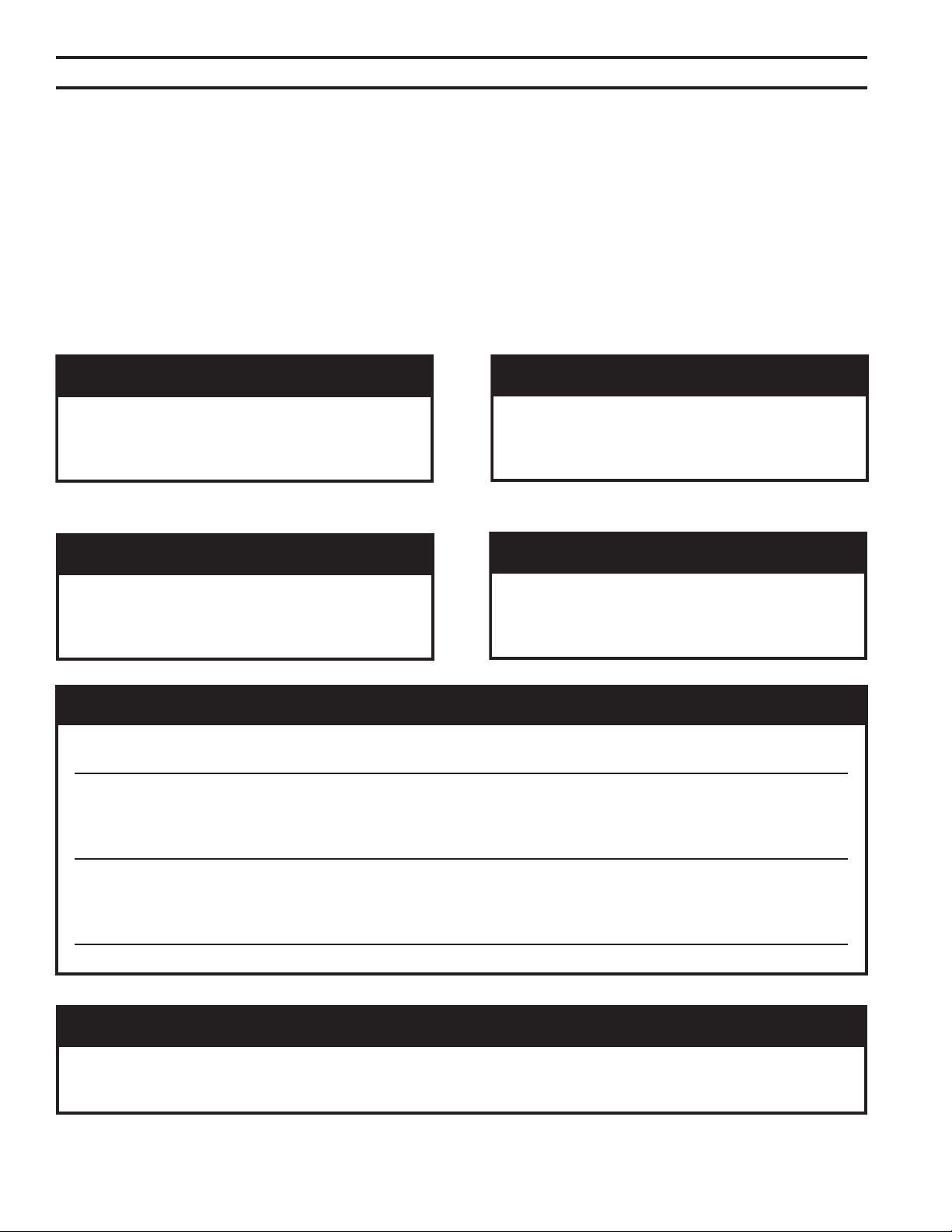

E. The heating units may be installed in a one-pipe system

with diverter fitting(s) for heating application only. The

location and quantity of diverter fitting(s) will affect the

flow to the unit. A single fitting located on the return

fromtheunitwillprovideminimalflow. Asinglefitting

located on the supply to the unit will provide increased

flow. Two fittings, one located on the supply and one

located on the return of the unit will provide the

maximumflowtotheunit. Consultthemanufacturer’s

instructions of the diverter fitting for additional informa-

tion. See Figure 3.

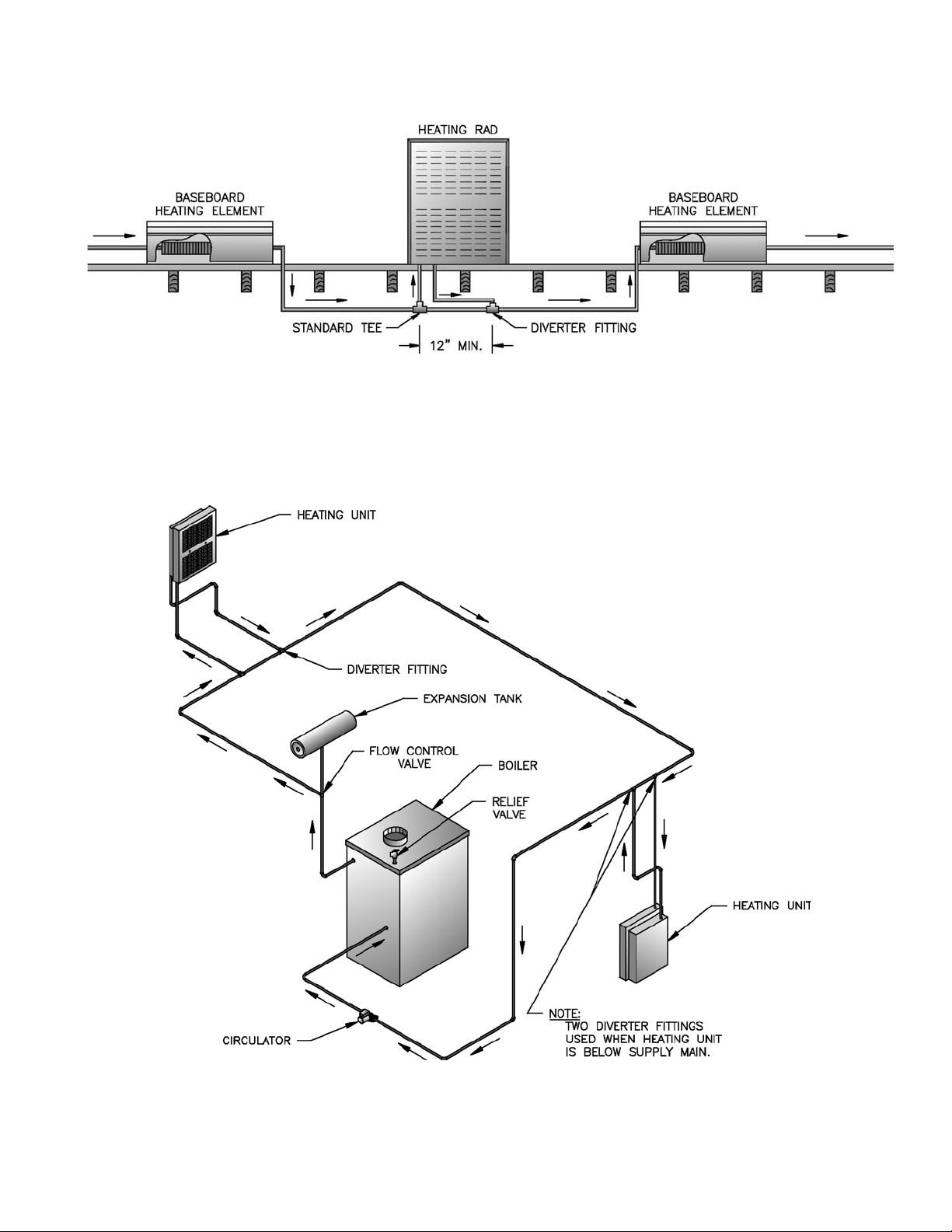

F. When the installation is to provide for heating and

cooling, it is highly recommended that a two pipe

reverse return distribution system be used. See Figure4.

It is also recommended that any piping carrying chilled

water be insulated and sealed with a suitable sealant as

necessary, to ensure condensation does not spill or

leak.

G. Before making connections to the units, the piping

should be flushed with water to remove dirt and

foreign matter from accumulating in the system.

ECITON

otegamaddnanoitareporeporpminitluseryamecnailppaepipylreporpoteruliaF

reporpehtfodnaeerfkaelyletulosba

signipipretawerussasyawlA.erutcurtsroecnailppa

.epytdnaezis

fonoitanimatnocnegyxoybdesuacsmelborprevoct

onseodytnarraWdradnatSs'mahnruB

.retawfonoitiddatneuqerfybdesuacpu-dliub)emil(elacsroretawecnailppa