1

Safety Information

GUIDELINES FOR USE:

All current and future users of Burntech® Fireplaces are

charged with the responsibility for full knowledge of the

information contained within this manual which includes:

Strict requirements for assembly.

Detailed instructions for installation.

Cautionary guidelines for use.

On-going maintenance instructions.

It is the responsibility of the installer, subcontractor and/or

the general contractor – whoever shoulders the liability for

installation of this product – to see to it that the work is in

complete compliance with the guidelines and instructions

in this manual. Note that the general contractor is the party

accountable for seeing that adequate clearances are provided

from all rebox surfaces per specications in this manual.

DO NOT USE A FIREPLACE INSERT OR OTHER

PRODUCTS NOT SPECIFIED FOR USE WITH THIS

FIREPLACE.

The Burntech® is Designed for Use Only with:

- Solid Wood Logs

- Plumbed LPG or Natural Gas Log Lighter.

- Plumbed ANSI Z21.60 Decorative Gas Log.

DO NOT USE OR STORE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR GASES IN OR NEAR THE

FIREPLACE!

ATTENTION: A re or an explosion could occur causing

property damage, injury or loss of life if you do not follow the

information in this manual!

NOTE: THIS MANUAL MUST BE REPRODUCED ONLY

IN ITS ENTIRETY.

Before Beginning the Installation

Read these instructions carefully before beginning the

installation of this replace. Also, if installing an ANSI Z21.60

Decorative Gas Log, read the gas log appliance manufacturer’s

literature regarding sizing and suitability for the installation into

this enclosure prior to installation.

Statement of Intended Use:

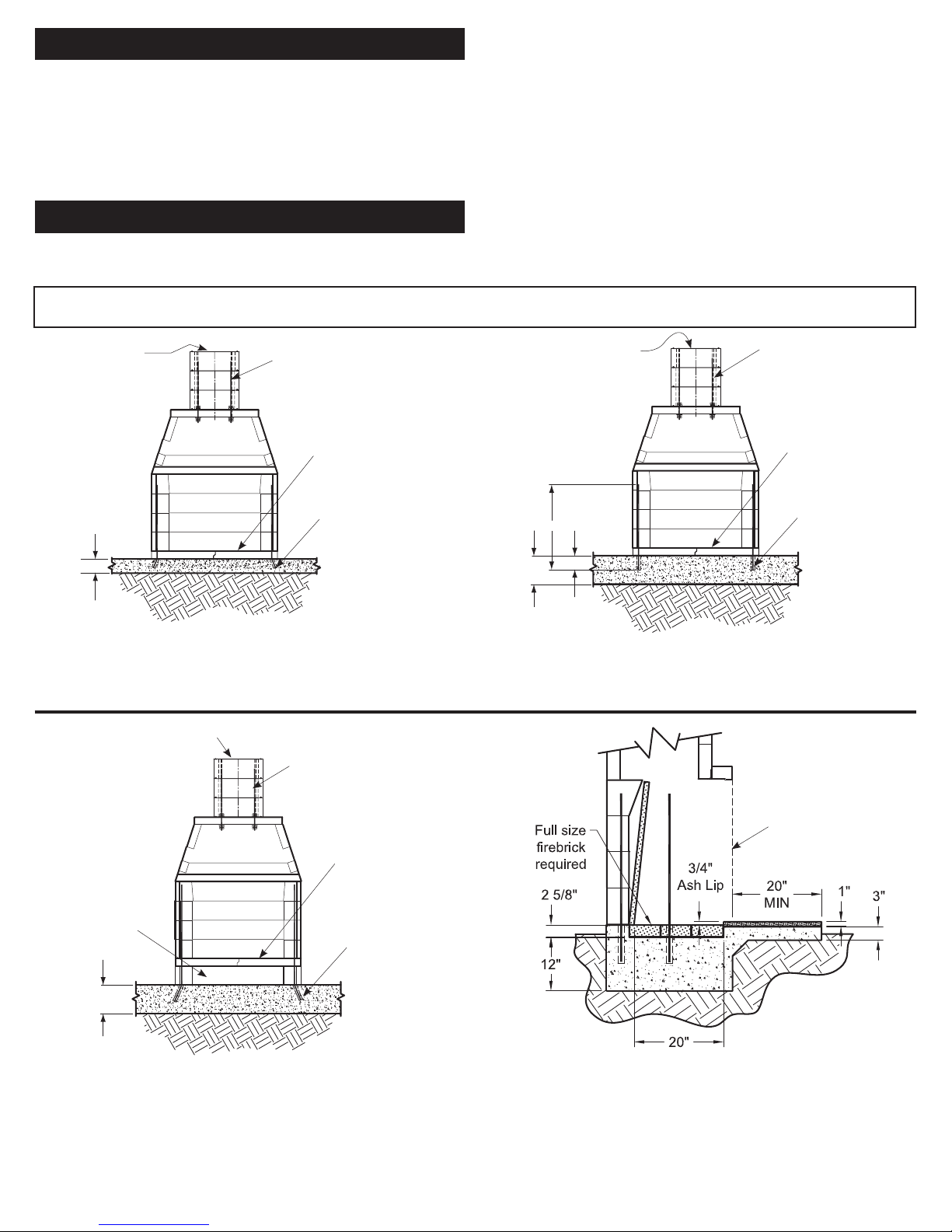

The Burntech® Masonry Fireplace is a modular refractory

masonry unit designed for eld assembly. The rebox is

constructed using pre-cast, interlocking refractory blocks.

The blocks are then secured to each other using Mortar. The

system includes all parts necessary for the assembly of a

complete masonry replace. In addition to the basic enclosure,

a standard 1-1/8” thick, high temperature refractory brick is

required to line the interior of the rebox and can be purchased

from the manufacturer.

These replaces are not intended to serve as a primary

heat source, rather, the replace was expressly created as a

supplemental source of heat. The unit is designed for use with

solid fuels such as cord wood.

WARNING:

Any application other than the “Intended Use” as stated above

is in violation of the manufacturer’s instructions and is hereby

prohibited. Such violation may cause immediate hazard,

property damage or loss of life and will void all liabilities to the

manufacturer and will void all warranties explicit or implied.

WARNING: THIS FIREPLACE HAS NOT BEEN TESTED

FOR USE WITH AN UNVENTED GAS LOG SET. TO

REDUCE THE RISK OF FIRE OR INJURY, DO NOT

INSTALL AN UNVENTED GAS LOG SET INTO FIRE-

PLACE.

WARNING: THIS FIREPLACE HAS BEEN TESTED FOR

USE WITH OPTIONAL GLASS DOORS FROM CROWN-

BRECKINRIDGE OR MCKENZIE-PENDELTON ONLY.

WARNING:

For all OFS-33,39,44 contained within a framed structure:

Install only approved, listed UL 103-12” I.D. ClassA Chimney

System.

For OFS-44 Contained within a framed structure: Install only

approved, listed UL 103-14” I.D. Class A Chimney System.

For OFS-63 Contained within a framed structure: Install only

approved, listed UL 103-16” I.D. Class A Chimney System.

Chimney maximum height: 40 feet

Chimney minimum height: 14 feet (with offset = 17 feet)

2 offsets maximum.

Important: Follow the chimney pipe manufacturer’s

instructions on the installation of their specic ue system.