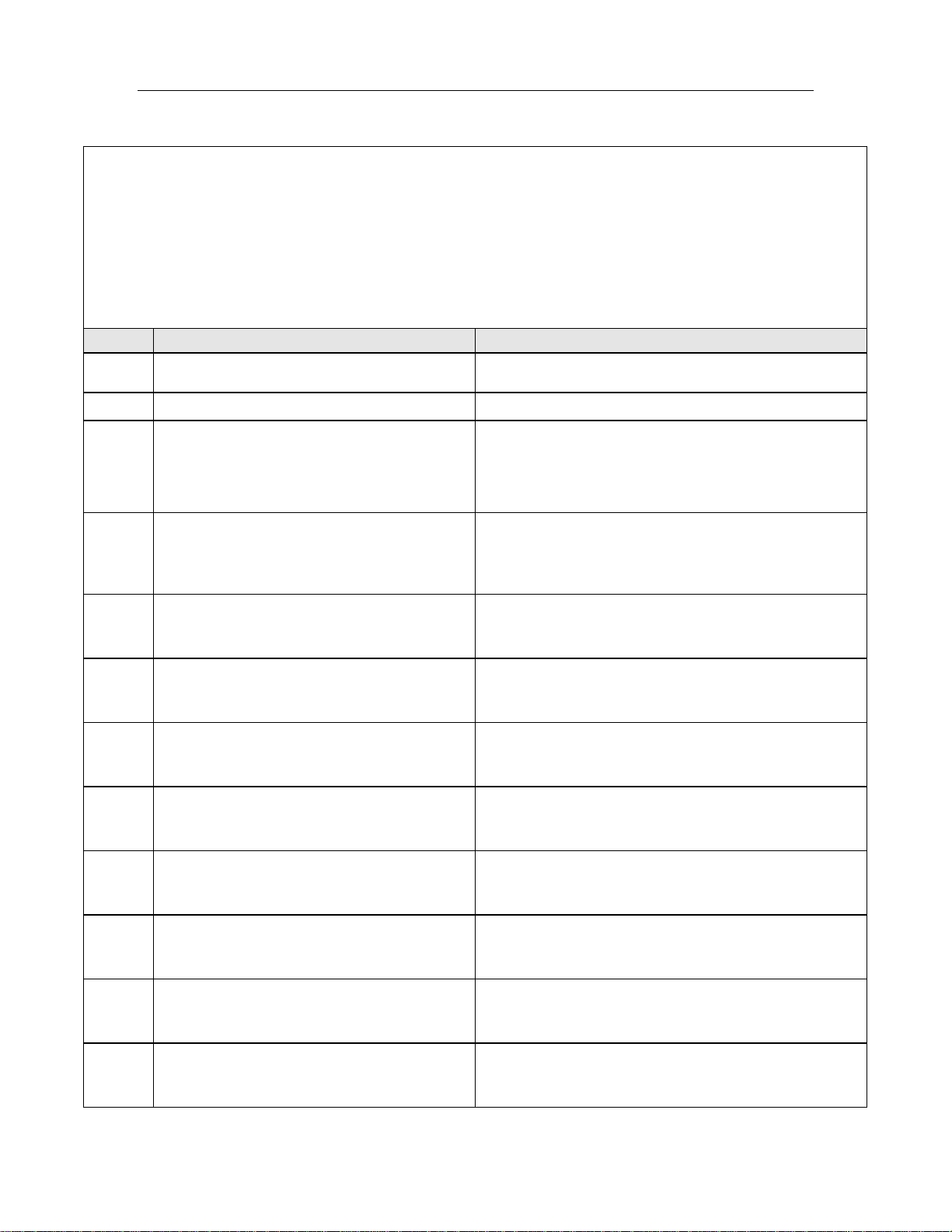

PART 1 –SYSTEM OVERVIEW

MYX-12383 REPLICATOR 1100 (for AC lifters)

“SOL”connector I/O ratings

Note: All solenoids are served by the same fuse, FU2, 6.3 A, on the

rear panel. Maximum total current of the solenoids is limited by this

fuse.

PIN # DESCRIPTION RATINGS

9Input -Solenoid Hot 24 V max AC, 50/60 Hz, or 24 V max DC, 6.3 A max

33 Input -Solenoid Neutral Neutral or common for pin 9

2, 6,

11, 17,

21, 24,

35, 30

Output -Solenoid Neutral Neutral or common for pins 1, 5, 10, 16, 20, 23, 34,

and 29

3, 7,

12, 18,

22, 25,

36, 31

Chassis ground 18 AWG wire

1Oxygen Vent Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

5Second Stage Cut O2 Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

10 Lo Preheat Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

16 Ignite Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

20 First Stage Cut Oxygen Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

23 Water Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

34 Hi Preheat Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.

29 Auxilliary Solenoid Output 24 V max AC, 50/60 Hz, or 24 V max DC.

2 A max, but on same 6.3 A fuse, FU2 with 7 other

solenoid outputs.