4

•The Kup-L-Weld® II can be set to draw from a minimum of

19 amps up to a maximum of 28 amps.

•After twisting together the ends of a thermocouple wire, use

the alligator clamp holder to grasp the thermocouple wires

about one inch from the ends to be welded.

•Press the “WELD” button and strike an arc between the

carbon rod and wires.

•Voltage is present on the carbon rod only while the “WELD”

button is depressed.

APPROVED WIRES

•The Kup-L-Weld® II welder will accommodate wire sizes

from 14 gauge to 30 gauge in chromel-alumel, chromel-

constantan, copper-constantan, iron-constantan, and

platinum-rhodium.

CURRENT ADJUST

•The “Current Adjust” control can be set at maximum for

most work.

•If diculty is experienced with excessive heat on smaller

gauge wires, the “Current Adjust” control can be turned

counter-clockwise to achieve a lower setting.

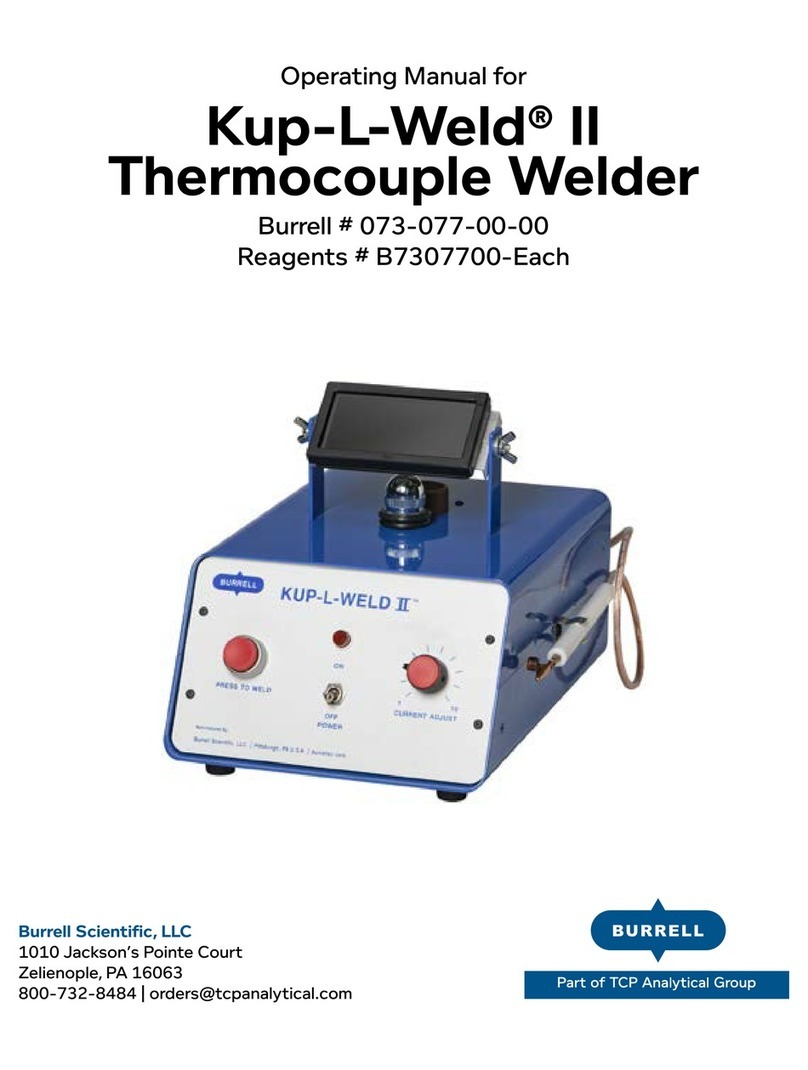

SAFETY FEATURES

•For operator safety, a ash protection viewing screen

is standard, however the screen is not to be used as a

substitute for proper eye protection.

•The viewing screen can be locked in the desired position by

tightening the thumb screws.

•The Kup-L-Weld® II welder has a 115-volt lamp which

illuminates the carbon rod contact area while welding. This

very useful feature adds to the overall safety of the unit

because it is not necessary to look over the viewing screen

to observe weld contact.

•The lamp may be replaced by removing the lamp shield,

then removing the lamp.

•Safety goggles or glasses are required, despite these safety

features.