R

2

Thank you for your purchase of this Elcometer 355 Coating Thickness Gauge. Welcome to Elcometer.

Elcometer are world leaders in the design, manufacture and supply of coatings inspection equipment. Our

products cover all aspects of coating inspection, from development through application to post application

inspection.

The Elcometer 355 Coating Thickness Gauge is a world beating product. With the purchase of this gauge

you now have access to the worldwide service and support network of Elcometer. For more information visit

our website at www.elcometer.com

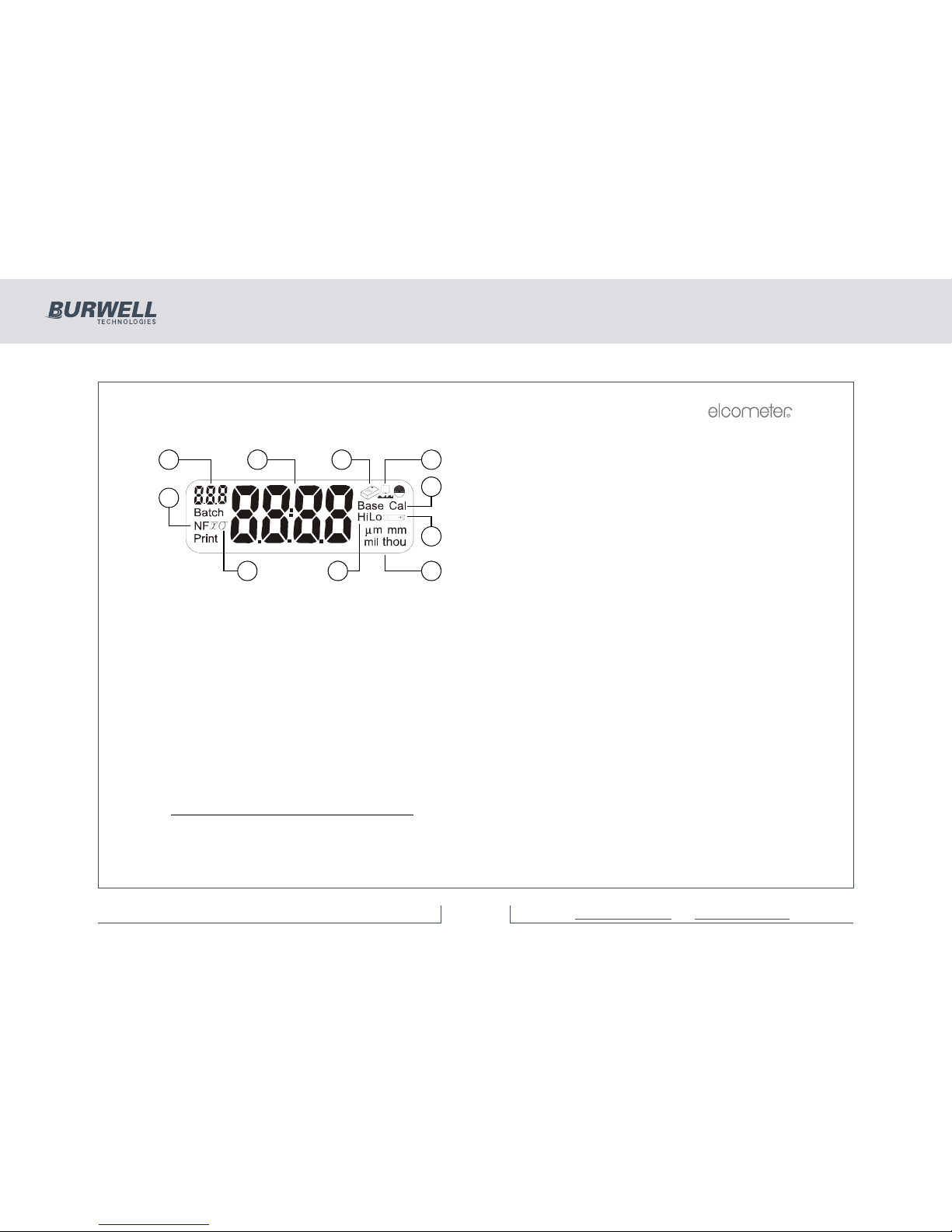

1 ABOUT YOUR GAUGE

The Elcometer 355 Coating Thickness Gauge is a handheld gauge for fast and accurate measurement of

the thickness of coatings.

With a memory of up to 5000 readings in multiple batches and accuracy to ±1%, your gauge is a measuring

system packed with time saving and cost cutting features.

1.1 STANDARDS

The Elcometer 355 can be used in accordance with the following National and International Standards:

FERROUS (F)

ASTM B 499, ASTM D 1186-B, ASTM G 12, BS 3900(C5), BS 5411 (11), DIN 50981, IMO MSC.215 (82),

IMO MSC.244(83), ISO 1461, ISO 2063, ISO 2808-7C, supersedes ISO 2808-6A, BS 3900-C5-6A, BS

5411-11, DIN 50981, ISO 2808-12, ISO 19840, NF T30-124, SSPC-PA2.