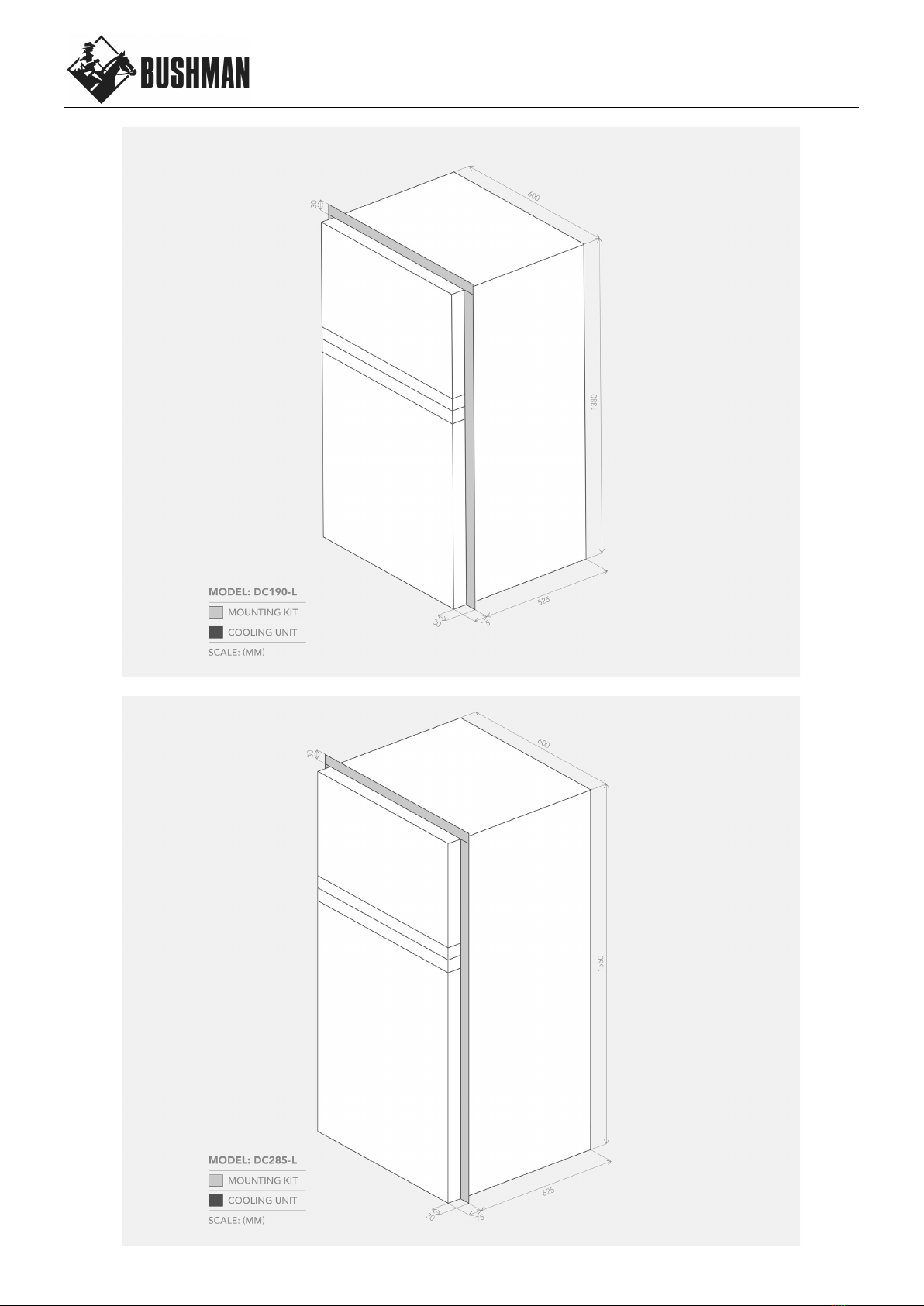

INSTALLATION IN A CAVITY WITH THE MOUNTING KIT

DC-L fridges are designed to be installed in a cavity. We recommend allowing a minimum 5mm gap in width

and height for ease of installation. A minimum gap of 50mm is recommended for the rear. Refer to the

following table for the recommended cut-out dimensions.

CUT-OUT CAVITY DIMENSIONS (MM)

VENTILATION

Two vents need to be provided from the rear of the fridge cavity to the outside environment, or to the general

area where the fridge is located. The vents should be located at the bottom and top of the fridge cavity and

have a free cross section of at least 300cm2 each. This allows for natural thermal air flows across the

condenser. As a general rule, the more ventilation you can provide, the better.

MOUNTING KIT

The mounting kit is first affixed to the side and top of the fridge cabinet using the screws provided.

Once the fridge has been connected to the power supply and moved into its final position, the mounting kit

can be affixed to the front of the cavity.

OPERATING THE FRIDGE

THERMOSTAT

• The cooling level can be set between 1 and 7.

• 7 is the coldest setting and 1 is the warmest.

EQUALISING THE FRIDGE

During the first 24 hours of operation, your compressor will operate for longer than usual. This process allows

the internal air temperature, food, drinks, condenser and insulation to equalise.

ENERGY SAVING TIPS

• Have a much ventilation as possible – the more the better.

• Keep the fridge out of direct sunlight whenever possible

• Only open the fridge or freezer door when necessary

• Allow hot food to cool down before placing inside the fridge

• Defrost the fridge as soon as a layer of ice forms

• Set the fridge to be only as cold as necessary

CLEANING

Wash the inside of your fridge with luke warm water and a mild soap. Never use abrasive or corrosive

cleaning agents, steel wool or scouring sponges. A soft sponge, towel, or soft brush is recommended.

Always keep the inside of the fridge clean and dry. Remove any condensate water or ice which gathers in or

near the tray under the freezer compartment.

Be careful when opening or closing the freezer door if ice has been allowed to accumulate in this area.

Keep the doors of the fridge ajar when the fridge is not in use, to allow fresh air to circulate inside the fridge

compartment.