User Manual

7

relevant national security regulations.

Warning: The electric conductors are strictly prohibited to be connected with water

supply pipes, natural gas pipes and caliducts, otherwise, security accidents would be

induced.

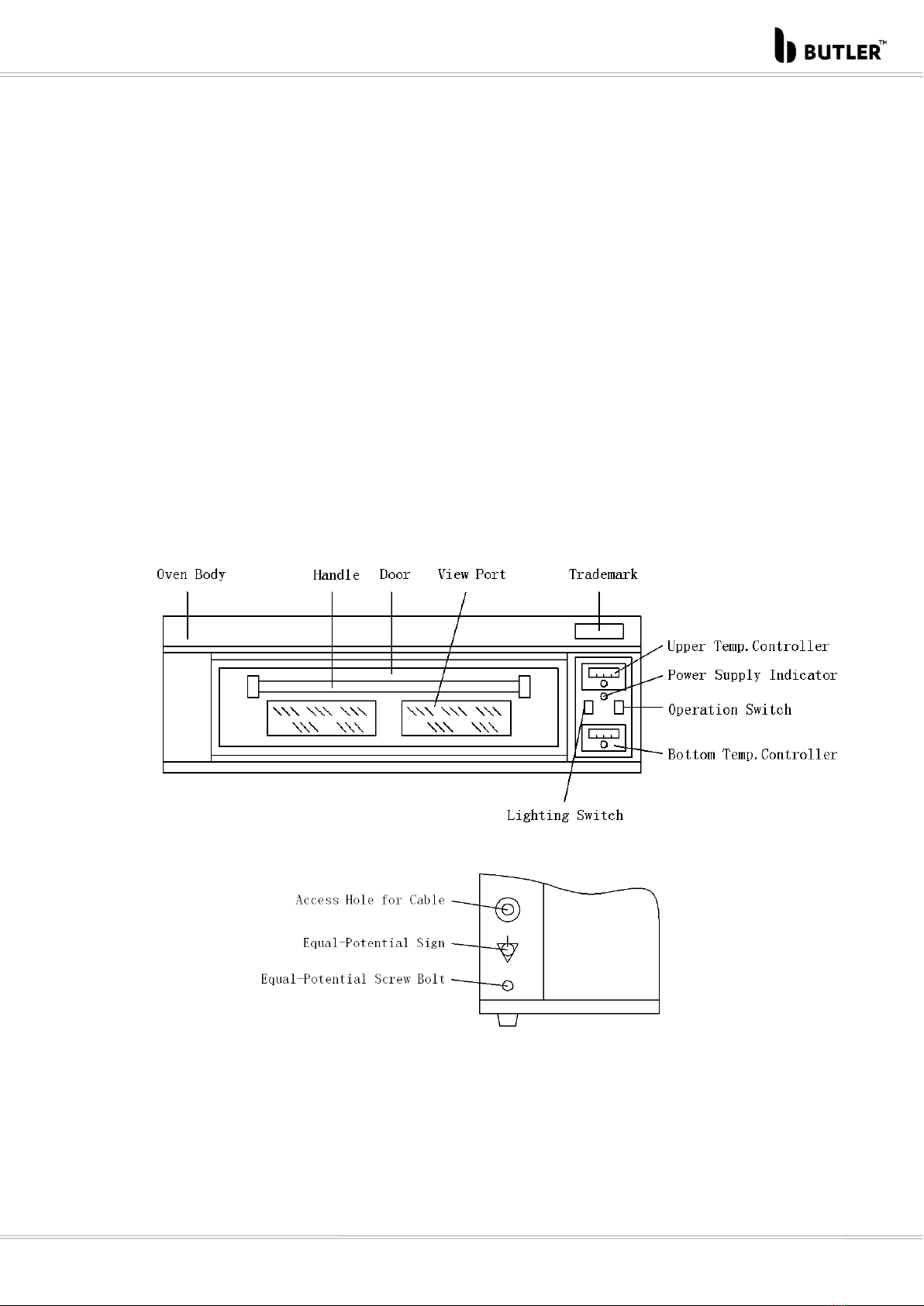

4. An equal-potential connection screw is foreseen on the back area of the machine. In case

that any other equipment inside the same room have equal-potential connections, the

equal-potential connection screw of this machine should be connected to an equal-

potential terminal of the other equipment through a copper conductor with a section area

of no less than 2mm2.

Operation Procedure

1. Before operation, pour water into the water tank until the surface of water reaches a height

of 10cm.

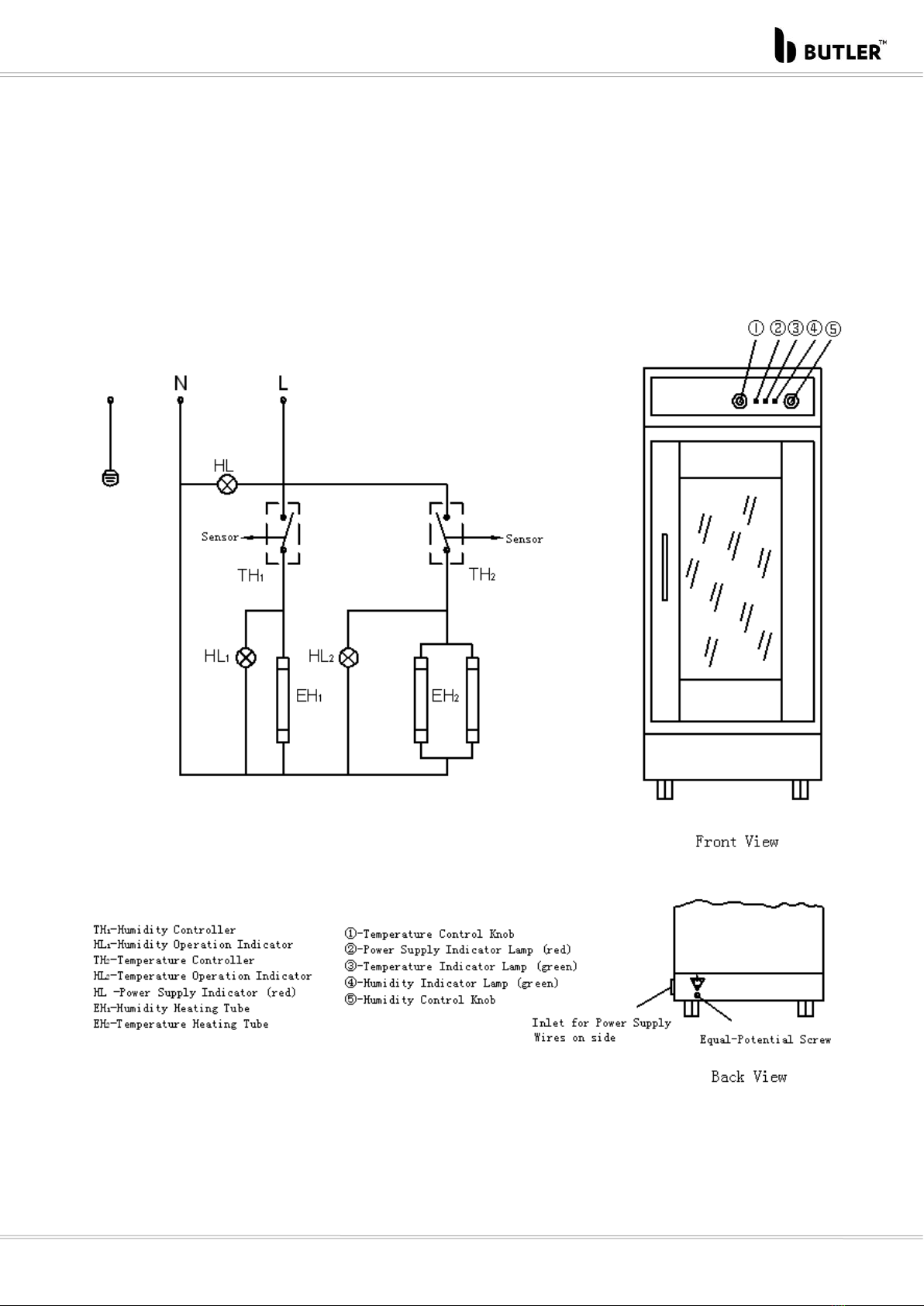

2. Insert the three-pole power supply plug of the Awaken Fermenting Box into a proper

socket, and then turn on the circuit breaker in the power supply circuit, at this moment,

the power supply indicator lamp will light(red). Turn the temperature and humidity control

knobs on the control panel to desired position, and then, the temperature and humidity

indicator lamps will light(green), indicating that the Awaken Fermenting Box is in operation

and is capable of automatic operating within the setting range of temperature and humidity.

3. When the machine is out of operation, the power supply should be switched off so as to

insure your safety.

4. The machine is equipped with a water-lacking protection device. In case that the red power

supply indicator lamp is on and that the machine fails to operate even if the temperature

and humidity control knobs have been adjusted, please check for water level inside the

water tank and pour water into it until the water surface reaches a standard level, then, the

machine will be able to operate. In case that the machine still fails to operate, the power

supply should be switched off immediately and the machine needs to be inspected and

repaired by professional technicians.

Attention and Maintenance

1. Regularly and often check the water level inside the water tank and insure that heating

tubes are dipped under the water surface so as to prevent the electro-thermal tubes from

being burned out. In case that these is no water inside the water tank, switching on the

power supply will be strictly prohibited so as to avoid any personal injury.

2. The awaken fermentation temperature is between 35℃~40℃, too high temperature will

influence the normal reproduction of the yeasts or even cause the death of them.

3. The waterproof category of the machine is of ordinary grade (IPXO), and therefore it is

suitable for indoor operation only. The machine is strictly prohibited to be placed at a place

where spraying water may possibly occur. Cleaning the machine with water spraying from

a pipe or by dipping it into water will be strictly forbidden.

4. The inside or outside area of the box body should be kept clean. The water in the water

tank should be replaced at least one time each day. The water tank should be kept in an

condition of cleanliness and sanitation. In case any dirt occurs on the surface of the